Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Factory Customized Bn Disc Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Factory Customized Bn Disc Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Factory Customized Bn Disc Boron Nitride Ceramic)

Specification of Factory Customized Bn Disc Boron Nitride Ceramic

Manufacturing Facility Direct Custom-made BN Disc Boron Nitride Porcelain delivers outstanding performance for requiring applications. We make these discs specifically to your requirements. You inform us the diameter and density you need. We generate them. You obtain the precise size for your tools or procedure. This ceramic offers exceptional thermal conductivity. It relocates heat away quickly and effectively. This is vital for high-temperature operations. Points stay cooler and function better.

Electrical insulation is another crucial toughness. BN ceramic doesn’t conduct power. It works as a trusted barrier. You can utilize it securely in electrical systems needing isolation. Chemical resistance is impressive too. It deals with challenging problems. Acids, bases, and molten steels normally don’t influence it. This makes sure long life and reliability. Purity is crucial. Our high-purity boron nitride minimizes contamination risks. This is essential for sensitive procedures like semiconductor manufacturing or steel casting.

Machinability sets this product apart. You can equipment it right into complicated shapes relatively conveniently. This allows for custom-made functions beyond basic discs. Required slots, holes, or details shapes? It’s feasible. Surface area surface issues. We provide alternatives from common to extremely smooth. A smoother coating minimizes friction and wear. It additionally helps with launch residential or commercial properties, helpful in molding. Low rubbing is intrinsic. Components slide easily versus it. This lowers energy loss and part wear. Lubrication requires frequently reduce.

The product normally stands up to sticking. Molten steels and glass launch cleanly. This makes BN discs ideal for crucibles, setters, and linings. Thermal shock resistance is outstanding. It makes it through fast temperature changes without breaking. Heat it up fast or cool it down quickly. It handles the tension. Stamina stays efficient high temperatures. It does not compromise significantly when things get hot. This preserves structural integrity under thermal tons.

Applications prevail. Use it in semiconductor handling tools. It works well in high-temperature heaters and kilns. Steel and glass handling advantages substantially. Aerospace components utilize its homes. Research study labs count on its regular performance. This ceramic manages tough jobs reliably. It solves issues where other products stop working.

(Factory Customized Bn Disc Boron Nitride Ceramic)

Applications of Factory Customized Bn Disc Boron Nitride Ceramic

Factory tailored BN disc boron nitride ceramic fixes tough issues. This product deals with severe warm. It does not melt or degrade easily. Several manufacturing facilities need this. High-temperature kilns use BN discs. They work as linings or separators. Heater parts benefit too. BN discs resist thermal shock well. Abrupt temperature level changes do not break them. This is essential in steel handling. Foundries utilize BN discs in casting mold and mildews.

Electrical insulation matters in factories. BN ceramic is an outstanding insulator. It works also at extremely high temperatures. Semiconductor manufacturing requires this. BN discs different parts in development chambers. They avoid electric shorts. Power electronics use them likewise. BN keeps high-voltage equipment secure.

Chemical resistance is an additional key stamina. Harsh chemicals strike several materials. BN ceramic withstands acids, bases, and molten metals. Chemical plants make use of BN discs for seals and crucibles. Glass manufacturing facilities use them near liquified glass. Molten light weight aluminum handling needs BN components. The discs do not respond or pollute.

Customization is crucial. Every manufacturing facility configuration is different. BN discs can be made in certain sizes. Density can be changed. Holes or various other functions are added precisely. This ensures an ideal suitable for equipment. Machining is feasible. Manufacturing facilities get discs customized to their specific tools. This improves efficiency and lifespan.

BN ceramic is also unsafe. It has natural lubricity. This aids in moving parts. Bearings and sleeves occasionally use BN discs. Put on is lowered. Upkeep periods obtain longer. Metal creating tools make use of BN for release. Sticking is avoided.

Dealing with liquified products is vital. BN discs offer steady surfaces. They don’t wet quickly. Molten metals slide off easily. This is crucial for casting quality. Clean splitting up conserves time and product. Semiconductor crystal development relies on BN watercrafts and setters. Purity is maintained.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Customized Bn Disc Boron Nitride Ceramic

What customization options exist for BN ceramic discs?

Factories offer many choices. You pick the disc size and thickness. You select the exact boron nitride grade. Different grades suit different needs. You decide the surface finish. Options include smooth, textured, or specific roughness. You request special shapes. Simple holes or complex geometries are possible. Discuss your application details with the factory. They confirm what they can make.

Why choose boron nitride ceramic for demanding applications?

BN ceramic handles extreme conditions well. It withstands very high temperatures. It manages sudden temperature changes without cracking. It conducts heat fast like a metal. It blocks electricity completely. It resists most molten metals and chemicals. It doesn’t stick to materials. It offers low friction. These properties make it unique. It solves problems other materials cannot.

Where are customized BN discs typically used?

These discs see heavy use in high-temperature processes. They are common fixtures in semiconductor manufacturing. They serve as crucibles for melting metals. They act as insulators in high-power electronics. They function as components in plasma equipment. They are found in aerospace test environments. They support glass forming operations. Their stability under heat and corrosion is key.

How strong and durable are these ceramic discs?

BN ceramic is strong but brittle. It handles compression forces well. It resists thermal shock excellently. Avoid heavy impacts or bending stress. It maintains strength at temperatures over 2000°C in inert atmospheres. In air, it works reliably up to about 900°C long-term. Proper handling prevents chipping. It lasts a long time under correct operating conditions. Its wear resistance is good.

What support does the factory provide for custom orders?

Factories give technical advice. They help select the right BN grade. They assist with design feasibility. They provide quotes based on your specifications. They manage the manufacturing process. They offer quality control reports. They handle packaging and shipping. They solve production issues. Communicate your exact needs early. Good factories partner with you for success.

(Factory Customized Bn Disc Boron Nitride Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

The Ultra-Pure Processing Powerhouse – Boron Nitride Ceramic Barrel

High Thermal Conductivity Bn Tube/Bn Rod/Bn Plate/Heat Sink Boron Nitride /Bn Ceramics

Boron Nitride Aerosol Spray Boron Nitride Ceramic High Thermal Shock Resistance

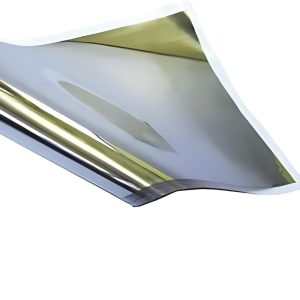

Chemically Stable Boron Nitride Ceramic BN Film

Heating & Semiconductor Applications Semicircular Bn Crucible Boron Nitride Ceramic