Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Good Thermal Conductivity Boron Nitride Ceramic Sleeve)

Specification of Good Thermal Conductivity Boron Nitride Ceramic Sleeve

The Good Thermal Conductivity Boron Nitride Ceramic Sleeve is made for high-performance applications requiring effective heat management. It is made from costs boron nitride ceramic, a material recognized for outstanding thermal conductivity. This home enables the sleeve to transfer warmth rapidly, minimizing hotspots in devices. The ceramic structure makes certain security also under extreme temperature levels, making it suitable for environments up to 1800 ° C.

The sleeve provides reduced thermal development, preserving form and integrity during fast temperature level modifications. This prevents breaking or buckling, common problems in metal or polymer choices. Its non-reactive surface area stands up to rust from acids, alkalis, and molten steels. This makes it ideal for usage in severe chemical or metallurgical processes.

Electrical insulation is another key feature. The product does not conduct power, decreasing dangers of short circuits in electronic or high-voltage systems. The smooth surface lessens friction, prolonging the life-span of moving components in machinery. It is light-weight contrasted to steel sleeves, reducing energy consumption in turning equipment.

Machining precision makes certain limited resistances for tailor-made applications. The sleeve can be produced in numerous shapes and sizes to meet specific industrial demands. It is compatible with heating systems, activators, and semiconductor manufacturing devices. The material produces no unsafe gases, lining up with safety and environmental standards.

Longevity is a priority. The ceramic resists wear from abrasion, keeping performance over extended periods. Upkeep demands are minimal, minimizing downtime and operational expenses. The sleeve works in vacuum cleaner conditions, increasing its use in aerospace or innovative product handling.

Cost performance comes from extensive service life and minimized power use. Industries like metallurgy, electronic devices, and power benefit from enhanced heat monitoring and tools reliability. The boron nitride ceramic sleeve is a functional remedy for requiring thermal and mechanical obstacles.

(Good Thermal Conductivity Boron Nitride Ceramic Sleeve)

Applications of Good Thermal Conductivity Boron Nitride Ceramic Sleeve

Excellent thermal conductivity boron nitride ceramic sleeves manage heat well. These sleeves relocate heat far from hot spots quick. They operate in electronics. They maintain components like semiconductors and circuit boards cool down. This quits getting too hot. It makes tools last much longer. It aids electric lorry batteries remain risk-free. High warm can damage batteries. The sleeves spread out heat uniformly. This stops troubles.

They work in industrial equipments. Devices produce lots of warm when running. The sleeves shield components like sensing units and heating units. They manage severe temperature levels. Heaters and activators utilize them. The sleeves insulate heat-sensitive parts. This keeps devices running efficiently.

They protect electrical power. Boron nitride does not carry out electrical power. This works in high-voltage systems. High-voltage line and transformers require insulation. The sleeves quit stimulates or short circuits. They make equipment safer. Aerospace systems utilize them. Electronic devices in planes deal with tough conditions. The sleeves safeguard against heat and electricity.

They resist chemicals. Harsh chemicals damages many products. Boron nitride remains stable. It operates in chemical plants. Pipes and valves deal with destructive fluids. The sleeves secure these parts. Labs use them for liquified steel handling. Semiconductor manufacturers depend on their pureness. No impurities influence manufacturing.

They last long. Boron nitride is difficult. It takes care of wear and friction. Bearings and seals in devices encounter continuous activity. The sleeves decrease damage. Reducing devices utilize them. Tools remain sharp much longer. Upkeep expenses drop.

They help lasers and optics. Lasers produce warmth during use. The sleeves cool laser parts quickly. Clinical lasers require precision. Warm can misshape results. The sleeves keep temperature levels stable. Optical fiber use them too. Secure heat improves signal top quality. Interaction systems work much better.

These sleeves fit several industries. Electronics, production, power, and more depend on them. Their warmth administration boosts performance. Their durability cuts downtime. Their safety and security features avoid accidents. They address heat-related challenges silently.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Good Thermal Conductivity Boron Nitride Ceramic Sleeve

What makes boron nitride ceramic sleeves good for thermal management?

Boron nitride has high thermal conductivity. It moves heat away from hot spots efficiently. This material stays stable under extreme temperatures. It works better than many metals or plastics in heat transfer. The structure allows even heat distribution without degrading over time.

Where are these sleeves commonly used?

They suit high-temperature industrial setups. Examples include semiconductor manufacturing, furnace parts, and aerospace components. Electronics like high-power LEDs or laser diodes use them for cooling. They protect sensitive parts from overheating. Any application needing heat dissipation benefits from these sleeves.

How temperature-resistant are boron nitride ceramic sleeves?

They handle temperatures up to 1000°C in air. In non-oxidizing environments, they withstand over 2000°C. Most metals or polymers fail at lower temperatures. This makes boron nitride ideal for extreme conditions. It doesn’t melt or warp easily under heat stress.

Do these sleeves resist chemicals or corrosion?

Boron nitride is chemically inert. It doesn’t react with acids, alkalis, or molten metals. Corrosion isn’t an issue even in harsh settings. This durability extends the sleeve’s lifespan. It performs reliably in aggressive industrial processes.

Are boron nitride sleeves safe for handling?

They’re non-toxic and safe for most applications. No harmful fumes release under high heat. Dust from machining may irritate lungs—wear protective gear during processing. Once installed, they pose no health risks. They meet industrial safety standards.

(Good Thermal Conductivity Boron Nitride Ceramic Sleeve)

REQUEST A QUOTE

RELATED PRODUCTS

Pyrolysis PBN Boron Nitride Ceramic Nozzle Customization

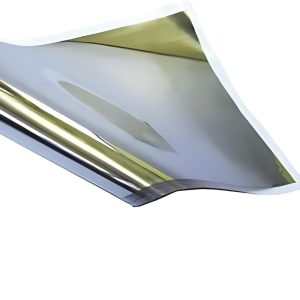

Chemically Stable Boron Nitride Ceramic BN Film

Boron Nitride CAS 10043-11-5 Ceramic Coating Daily Chemicals Chinese Factory

Ceramic Boron Nitride Nozzle for Gas Vacuum Metal Powder Atomizer

3-5 Micron BN Powder Boron Nitride Powder Ceramic Grade Factory Supply for Various Industrial Uses