Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

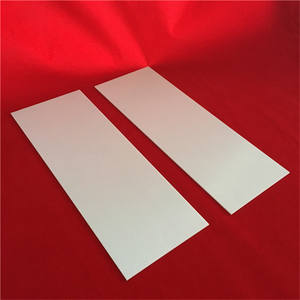

(High Temperature BN Boron Nitride Ceramic Tubes Rods Bars)

Specification of High Temperature BN Boron Nitride Ceramic Tubes Rods Bars

High Temperature BN Boron Nitride Porcelain Tubes Rods Night clubs withstand extreme heat. They operate in atmospheres as much as 2000 ° C. They stay strong and secure also under intense warmth. This fits heaters, reactors, and commercial procedures needing heats. They perform dependably in vacuum or inert gas ambiences.

These ceramics do not carry out electrical energy. They insulate effectively versus electrical currents. They withstand arcing and high voltage. This makes them risk-free for electronics and high-power systems.

BN ceramic resists most chemicals. It does not react with acids, alkalis, or liquified metals. This is important for steel casting, glass production, and chemical laboratories. It remains durable when revealed to harsh products.

The product is solid yet very easy to equipment. It is less breakable than other porcelains. Individuals can reduce, drill, or form it right into exact components without complicated steps. This minimizes manufacturing time and prices.

Requirement sizes are offered. Tubes, rods, and bars vary from 5mm to 100mm in size. Sizes reach up to 500mm. Custom-made sizes satisfy specific demands. This versatility fits varied industrial usages.

Industries like aerospace, metallurgy, and semiconductors use BN ceramics. Common applications consist of crucibles, insulators, thermocouple guards, and laser tools. They operate in atomic power plants because of radiation security.

BN ceramic handles quick temperature changes. It stands up to thermal shock, preventing splits from abrupt home heating or cooling. This reliability cuts downtime and maintenance expenses. The material’s low thermal growth guarantees constant efficiency.

High-purity grades suit semiconductor production. They protect against contamination in delicate procedures. Their non-wetting surface area homes improve efficiency in steel handling. These characteristics make BN porcelains a sensible choice for requiring conditions.

(High Temperature BN Boron Nitride Ceramic Tubes Rods Bars)

Applications of High Temperature BN Boron Nitride Ceramic Tubes Rods Bars

High-temperature BN boron nitride ceramic tubes, poles, and bars serve critical functions in markets calling for severe warm resistance and resilience. These elements manage temperature levels over 2000 ° C in inert atmospheres. They withstand thermal shock, chemical corrosion, and electric conductivity. This makes them ideal for high-stress atmospheres.

These ceramics are widely utilized in high-temperature heating systems. They operate as thermocouple defense tubes, heating elements, and insulation components. They preserve architectural stability under prolonged warm exposure. Steel handling markets rely upon BN ceramic rods and tubes for managing liquified metals. They prevent contamination and stand up to destructive reactions.

Semiconductor production uses BN ceramic bars for wafer handling. They provide electrical insulation in crystal development systems. Their non-reactive nature makes certain purity in sensitive processes. Aerospace and defense sectors apply BN tubes in rocket nozzles and thermal securing. They take care of extreme heat during propulsion.

The chemical industry benefits from BN ceramic rods in harsh atmospheres. They work as activator linings or support frameworks. They do not degrade when revealed to acids or antacid. BN ceramic bars are used in metallurgical procedures like continual spreading. They guide molten steel without sticking.

Welding and brazing procedures make use of BN ceramic tubes as components. They place materials specifically under high warmth. Their reduced rubbing surface area allows very easy release after processing. BN ceramics are likewise found in laser modern technology. They act as parts in high-power laser tools. They dissipate heat successfully to avoid damages.

These materials are vital in electronics for heat sinks and insulating components. They move warmth away from components while blocking electrical currents. BN ceramic bars are used in glass manufacturing. They handle liquified glass without contamination. Their adaptability throughout markets highlights their dependability in severe problems.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature BN Boron Nitride Ceramic Tubes Rods Bars

What are high temperature BN boron nitride ceramic tubes rods bars used for? These products handle extreme heat. They work in furnaces, semiconductors, and metal processing. They insulate well and resist chemical reactions. They are common in labs and factories needing materials that last under stress.

How hot can BN boron nitride ceramic tubes rods bars get before failing? They handle up to 2000°C in air. In oxygen-free settings, they withstand 3000°C. Most metals or plastics melt or break earlier. This makes them better for high-heat tasks.

Why pick BN boron nitride over other ceramics like alumina or silicon nitride? BN conducts heat faster but insulates electrically. It doesn’t stick to molten metals. Alumina cracks under rapid temperature shifts. Silicon nitride costs more. BN balances performance and price for many industrial uses.

Do BN boron nitride tubes rods bars need special care during use? Avoid sudden temperature jumps. Thermal shock can still cause cracks. Keep them dry. Moisture weakens them over time. Clean them with non-abrasive tools. Rough handling damages the surface.

Can these parts be customized in size or shape? Yes. Manufacturers cut BN ceramics into tubes, rods, or bars. Sizes vary by supplier. Custom shapes take longer and cost extra. Share exact needs early to check feasibility.

(High Temperature BN Boron Nitride Ceramic Tubes Rods Bars)

REQUEST A QUOTE

RELATED PRODUCTS

Excellent Machinability Heat Resistant Hot Pressed Boron Nitride Part BN Ceramic Crucible

Boron Nitride Rings High Temperature Resistant Customized Insulation BN Ceramic Ring Part

High Purity Boron Nitride Heater Heating Element

Customized Cubic Boron Nitride Blade CBN Solid Ceramic Blade Hard Outer Ring CNC Roll Brake Drum Milling Blade Carbide Insert

Boron Nitride Tube Hot Pressed Hexagonal Boron Nitride Ceramic Tube