Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

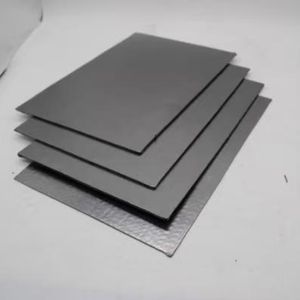

Overview of Industrial Bn Machined Boron Nitride Ceramic Parts

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Industrial Bn Machined Boron Nitride Ceramic Parts

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Industrial Bn Machined Boron Nitride Ceramic Parts)

Specification of Industrial Bn Machined Boron Nitride Ceramic Parts

Industrial BN machined boron nitride ceramic components are necessary components. They are made from an unique ceramic product. This material is mostly boron and nitrogen. BN porcelains use distinct buildings. They handle very heats well. This makes them good for warm environments. They are also exceptional electrical insulators. You can use them safely around electrical power.

These parts withstand chemical strike highly. Acids and bases typically do not damage them. They are also very unsafe. This all-natural lubricity reduces rubbing. Put on is much less of a problem. Thermal shock resistance is one more key feature. They can warm up or cool off quickly without cracking. This is essential for numerous commercial procedures.

Machining BN ceramics is feasible. We form them precisely. We make complicated geometries. We achieve tight tolerances. This consists of parts like nozzles, crucibles, insulators, and washing machines. Personalized forms are also available. We device them to your specific drawings. This makes certain an excellent fit.

People make use of these parts in many challenging industries. Factories and metal casting depend on them. Semiconductor manufacturing needs them. Aerospace applications utilize them also. They prevail in glass handling tools. High-temperature heating systems depend upon them. They function well in vacuum systems. Plasma applications use their properties.

BN parts last a long time. They endure harsh conditions better than metals. They outmatch other ceramics in thermal shock. Their low rubbing conserves power. Their electric insulation prevents shorts. Chemical resistance prevents deterioration. This reliability minimizes downtime. It reduces substitute prices overall. They are a smart choice for requiring work.

(Industrial Bn Machined Boron Nitride Ceramic Parts)

Applications of Industrial Bn Machined Boron Nitride Ceramic Parts

Industrial BN machined boron nitride ceramic components deal with extreme warmth and harsh chemicals. They function dependably where various other materials fall short. These custom-shaped parts are crucial throughout lots of challenging industries.

High-temperature applications count heavily on BN. Parts work as crucibles and setters in furnaces. They hold liquified metals like aluminum or glass during handling. BN remains stable and won’t infect the melt. This makes parts essential for pure semiconductor crystal development. BN insulators likewise border furnace burner. They safeguard the aspects and direct warm efficiently.

BN is an outstanding electrical insulator. It keeps high-voltage equipment secure. Parts separate electrodes in high-power plasma systems. They also protect vital elements within semiconductor processing tools. BN does regularly also under extreme electrical tension.

Chemical resistance is one more major benefit. BN components hold up against strong acids and liquified salts. This makes them excellent for chemical processing devices. They line reaction vessels and form sturdy nozzles. BN endures hostile settings where steels wear away quickly. This resistance prolongs component life considerably.

Thermal management uses BN’s distinct buildings. Parts conduct heat well in one instructions. They work as warmth spreaders or insulators in electronics. BN parts manage warm in lasers and high-power lighting systems. Efficient warmth control protects against overheating and damage.

BN parts offer low friction and use resistance. They create bearings and seals for high-temperature machinery. These parts reduce rubbing without conventional lubricants. This is vital in vacuum cleaner or cleanroom settings. BN likewise devices exactly right into intricate shapes. This enables custom parts for certain equipment requirements like plasma lanterns or sensor housings. Machined BN parts fit perfectly and carry out reliably. They last longer, reducing downtime and maintenance expenses.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Industrial Bn Machined Boron Nitride Ceramic Parts

What exactly are machined boron nitride ceramic parts?

They’re custom-shaped components made from boron nitride powder. Factories press and bake this powder into solid blocks. Then they machine these blocks into precise parts using special tools. These parts handle extreme heat and resist chemicals well.

How much heat can these boron nitride parts take?

They work fine in temperatures up to 850°C in air. They handle even higher heat, up to 3000°C, in vacuum or inert gases. Crucially, they resist thermal shock very well. This means they won’t crack easily when heated or cooled fast.

Do these parts conduct electricity?

No, they are excellent electrical insulators. This is true even at very high temperatures. It makes them perfect for electrical and electronic applications needing heat resistance. They keep electricity safely contained.

Are boron nitride parts good for wear resistance?

They have low friction, acting like a solid lubricant. But their wear resistance is just moderate. They aren’t the best choice for high-abrasion situations where parts rub hard constantly. They work better in less severe sliding conditions.

What special care do these parts need?

Handle them carefully. They are brittle and can chip or crack if dropped or hit. Keep them very dry before heating them above 300°C in air. Moisture at high heat can cause slow surface degradation over time. Store them in a dry place.

(Industrial Bn Machined Boron Nitride Ceramic Parts)

REQUEST A QUOTE

RELATED PRODUCTS

Ceramic Pyrolytic Boron Nitride Part

High Quality One End Open and the Other End Closed Boron Nitride Ceramic Tube BN Thermocouple protection Pipe

Superior Dielectric Strength Hpbn Ring Boron Nitride Ceramic

Hbn Boron Nitride Ceramic Precision Part for Hot Press Industry Ceramic

Boron Nitride Ceramic Boron Nitride Insulator Wear Resistance