Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

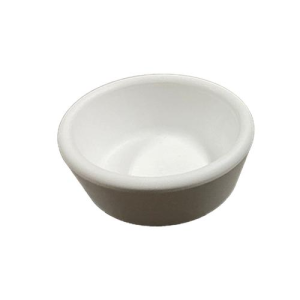

(The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring)

Specification of The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring

The Heat-Withstanding Hero in High-Tech Frontiers– the High Pureness Boron Nitride Ceramic Ring– masters severe atmospheres. This sophisticated product handles temperatures as much as 2000 ° C in inert gases. It continues to be stable in air up to 900 ° C. The ring stands up to thermal shock, making it ideal for quick heating-cooling cycles. Its low density decreases component weight without compromising efficiency. The ceramic ring operates smoothly in corrosive atmospheres. It stands up to acids, antacid, and molten metals. This makes certain toughness in severe commercial setups. The material’s high thermal conductivity enables efficient warmth distribution. It stops localized getting too hot in essential systems. Electric insulation residential or commercial properties decrease short-circuit risks in high-voltage applications. The ring keeps architectural honesty under mechanical anxiety. It withstands wear, expanding equipment life-span in high-friction environments. Accuracy machining makes sure limited dimensional resistances. Custom-made dimensions fit specific design demands. Standard inner diameters vary from 5mm to 500mm. Wall surface density options vary between 1mm and 50mm. Surface area surface alternatives consist of polished or matte textures. The brightened version reduces particle adhesion in vacuum systems. The matte finish boosts hold in setting up processes. High pureness levels surpass 99.9%. This minimizes contamination in semiconductor production. The ceramic ring follow aerospace-grade material criteria. It fulfills RoHS and REACH guidelines for worldwide usage. Lubricity properties minimize the demand for additional finishes. This streamlines maintenance in high-temperature machinery. The material’s non-wetting behavior avoids steel attachment throughout metal casting processes. It acts as a trustworthy crucible liner in metallurgy. The ring’s low thermal development coefficient makes sure shape stability across temperature level arrays. It fits safely in accuracy equipment without warping. Radiation resistance makes it appropriate for nuclear applications. Biocompatibility allows usage in clinical device manufacturing. The item undertakes rigorous top quality screening. Each batch gets look for cracks, porosity, and density. Performance uniformity is guaranteed across production runs. Custom-made finishings enhance functionality for specialized uses. Options consist of anti-oxidation layers for extended air exposure. The High Pureness Boron Nitride Ceramic Ring sustains technology in electronic devices, energy, and progressed production. It links the void between severe functional demands and material dependability.

(The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring)

Applications of The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring

The Heat-Withstanding Hero– High Pureness Boron Nitride Ceramic Ring– plays an essential role in state-of-the-art industries. Its special homes make it ideal for extreme environments. It handles intense warm, stands up to rust, and protects power. These features resolve obstacles in sophisticated production and technology.

Semiconductor manufacturing counts on this ceramic ring. Chip-making tools encounters temperatures above 2000 ° C. The ring stays stable, making sure accurate procedures. It protects against contamination in vacuum cleaner chambers. This keeps silicon wafers pure, enhancing chip top quality.

Aerospace engineers utilize the ring in rocket components. Engine components withstand quick temperature changes. The product’s thermal shock resistance prevents cracks. It shields sensors and electronics from severe warm. This enhances security and performance throughout goals.

The electronics industry benefits from its electrical insulation. High-power devices create excess warm. The ring isolates components while managing temperatures. It prolongs the life-span of gadgets like lasers and power converters.

Chemical handling plants utilize it in rough responses. Aggressive acids and molten steels damages equipment. The ring stands up to chemical disintegration. It secures activators and safeguards parts. This lowers downtime and upkeep costs.

LED manufacturing depends on the ring for crystal development. Developing sapphire crystals requires controlled high-heat conditions. The ring keeps security in furnaces. It ensures consistent crystal structures, improving LED illumination and effectiveness.

Additive manufacturing adopts the ring for 3D printing steels. Printers operate at extreme temperature levels. The ring lines printing chambers, consisting of warm and stopping bending. This enables exact metal part manufacturing.

Renewable energy systems utilize it in solar and nuclear technology. Solar cell production entails high-temperature coating procedures. The ring sustains consistent movie deposition. In nuclear reactors, it protects components from radioactive heat.

The High Purity Boron Nitride Ceramic Ring adapts to diverse requirements. It combines strength, thermal monitoring, and durability. Industries trust fund it to press technical limits. Its function in development grows as demands for high-performance materials climb.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring

What is a high purity boron nitride ceramic ring?

This ring is made from boron nitride ceramic. It has high purity. It handles extreme heat. It works in tough conditions. It keeps its shape. It resists damage.

Where is this ceramic ring used?

It fits in high-tech industries. Factories use it in aerospace. Labs use it in electronics. Machines need parts that last. This ring works in furnaces. It works in reactors. It works where temperatures jump.

Why pick this ring over others?

It beats metals and regular ceramics. Metals melt or warp. Regular ceramics crack. This ring stays strong. It insulates electricity. It doesn’t corrode. It cuts downtime. It saves money.

How hot can this ring get before failing?

It handles up to 1800°C in air. It handles 2200°C in vacuum. Most materials fail below this. It cools fast. It won’t break from sudden heat changes.

How long does this ring last?

It lasts years with care. Clean it regularly. Check for wear. Avoid harsh chemicals. It resists most reactions. Replace it if cracks appear. It needs little upkeep.

(The Heat-Withstanding Hero in High-Tech Frontiers – High Purity Boron Nitride Ceramic Ring)

REQUEST A QUOTE

RELATED PRODUCTS

High temperature high purity 99% BN boron nitride crucible

High Purity 99% Boron Nitride Advanced Composite Pipe BN Ceramic Heat Shield Tube

Ceramic Profiled Boron Nitride BN Ceramic Products

High Quality Boron Nitride Ceramic Boat Evaporation Boats Ceramics Boron Nitride Crucible Boat

High Working Temperature Corrosion Resistance Boron Nitride Gasket