Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Boron Nitride Ceramic

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Boron Nitride Ceramic

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic)

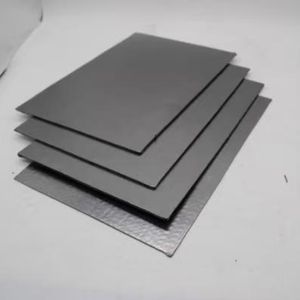

Specification of thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic

Thermal shock resistance boron nitride insulator hot press ceramic is created for severe temperature modifications. This material takes care of quick heating & cooling without fracturing. Boron nitride (BN) ceramic has high thermal conductivity and low thermal growth. These properties make it suitable for environments with unexpected temperature changes. The framework of boron nitride consists of hexagonal layers. These layers permit the material to take in stress and anxiety from thermal expansion differences. Other porcelains usually fail under similar conditions. BN insulators preserve architectural honesty over repeated thermal cycles.

The thermal shock resistance originates from a mix of elements. BN ceramic carries out warmth rapidly. This minimizes temperature gradients within the product. Reduced slopes mean less internal anxiety. The material likewise broadens minimally when heated. A low coefficient of thermal growth prevents warping or fracturing. These attributes let the insulator work in temperatures from -200 ° C to 900 ° C. Performance remains steady even during rapid shifts.

Mechanical toughness remains high at raised temperature levels. BN ceramic resists deformation under tons. Warm press manufacturing guarantees a dense, consistent framework. This procedure removes porosity. A pure, dense material resists wear and corrosion. Chemical stability is an additional benefit. BN does not react with the majority of acids, antacid, or molten steels. It functions well in aggressive commercial environments.

Applications consist of high-temperature furnaces, semiconductor production, and aerospace parts. The material works as crucibles, thermocouple tubes, and diffusion obstacles. In steel handling, BN insulators take care of molten alloys. Electronic devices utilize it for warm dissipation in power devices. The warm press technique warranties exact forms and smooth surfaces. Custom dimensions and geometries are attainable for details demands.

Thermal conductivity arrays between 25-30 W/m · K. Thermal expansion coefficients stay listed below 3 × 10 ⁻⁶/ ° C. Flexural strength exceeds 60 MPa at area temperature. Electrical insulation buildings protect against present leakage. Dielectric stamina reaches 40 kV/mm. These specs make BN ceramic a reputable selection for demanding thermal management jobs. Customers benefit from longer equipment life and minimized downtime. Maintenance prices drop as a result of the product’s longevity.

(thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic)

Applications of thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic

Thermal shock resistance boron nitride insulator warm press ceramic takes care of extreme temperature level changes without damages. This material functions well in high-heat settings. It keeps its shape and strength under rapid home heating or air conditioning. Industries requiring reputable efficiency in hard problems utilize it widely.

Steel processing uses this ceramic for lining heating systems and molds. It stands up to unexpected temperature adjustments throughout casting or creating. This lowers downtime from worldly failing. Equipment lasts longer. Production efficiency improves.

Semiconductor making relies upon this insulator for wafer processing. High temperatures take place during production. The ceramic’s stability stops contamination. It makes sure regular lead to chip manufacture. Electronics take advantage of higher integrity.

Aerospace applications consist of heat shields and engine components. Components face severe heat during trip. Thermal shock resistance avoids splits or bending. Safety and security and durability increase. Maintenance prices drop.

Electronics like LEDs and power devices utilize this product for warmth monitoring. It conducts heat away from sensitive components. Quick air conditioning cycles do not harm it. Gadget lifespan extends. Performance remains constant under stress and anxiety.

Protective coverings made from this ceramic guard tools and equipment. Surfaces stand up to thermal tiredness in high-heat environments. Deterioration decrease. Devices remain useful longer. Replacement regularity decreases.

The ceramic’s non-reactive nature fits chemical processing devices. It withstands deterioration from acids or liquified metals. Security in hostile settings keeps operations smooth. Leakages or failures end up being unusual.

Custom shapes are possible due to the hot press method. Suppliers create components tailored to details demands. Versatility in layout satisfies varied commercial needs. Waste decreases. Performance rises.

This boron nitride ceramic addresses problems in high-temperature areas. Its toughness and flexibility make it a leading selection for difficult applications. Industries achieve far better end results with fewer interruptions.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic

Thermal shock resistance refers to a material’s ability to withstand sudden temperature shifts without cracking. Boron nitride insulators excel here. They transfer heat quickly and expand minimally when heated. This reduces internal stress caused by rapid heating or cooling. Materials without these properties often fail under similar conditions.

Boron nitride is ideal for thermal shock resistance due to its unique structure. It combines high thermal conductivity with low thermal expansion. Heat spreads evenly, preventing localized stress. The material remains stable even under extreme temperature swings. This makes it superior to many traditional ceramics.

The operating temperature range for boron nitride insulators typically spans -200°C to 900°C in oxidizing environments. In inert or vacuum conditions, it withstands up to 1800°C. Performance depends on purity and manufacturing quality. Specific grades may vary. Always check the product specifications for exact limits.

Common applications include high-temperature furnaces, semiconductor manufacturing, and aerospace components. These industries rely on rapid heating or cooling processes. Boron nitride insulators prevent equipment failure in metal casting molds or electronic substrates. They ensure reliability in environments where temperature changes are sudden and extreme.

Proper care extends the lifespan of boron nitride insulators. Avoid mechanical impact during handling. Clean surfaces regularly to prevent contamination from dust or chemicals. Store in dry conditions to minimize moisture absorption. Inspect for cracks or wear before reuse. Follow manufacturer guidelines for installation and maintenance.

(thermal shock resistance thermal shock resistance boron nitride insulator hot press ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

HBN Custom Boron Nitride Ceramic Parts

Customized Boron Nitride Ceramic Rod Ceramic Protection Insulating Rod Shaft Part

Pyrolytic Boron Nitride Ceramic Crucible PBN Boat for Vacuum Melting

Factory Supply Hexagonal Boron Nitride Powder Ceramic Cubic Boron Nitride Powder

Hexagonal Boron Nitride Machinable BN bar Boron Nitride Insulator Ceramic Rod