Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications

Boron Nitride (BN) ceramic is a unique material renowned for its exceptional properties, making it highly valuable in various industrial applications. It exists in multiple forms, primarily hexagonal boron nitride (h-BN), cubic boron nitride (c-BN), and wurtzite boron nitride (w-BN). Hexagonal BN, the most common form, is often compared to graphite due to its lubricious and thermally conductive yet electrically insulating nature. Boron Nitride ceramics are synthesized under high temperatures and pressures, offering a rare combination of properties not found in many other materials.

Features of Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications

Thermal Conductivity: Excellent thermal conductivity, especially in the hexagonal form, allowing efficient heat dissipation.

Electrical Insulation: Outstanding electrical insulation properties make it ideal for electrical applications requiring thermal management.

Chemical Stability: Highly resistant to chemical attacks, including strong acids and bases, ensuring durability in harsh environments.

Thermal Shock Resistance: Superior resistance to thermal shock, enabling it to withstand rapid temperature changes without cracking.

Mechanical Strength: Good mechanical strength at both room and elevated temperatures, although this can vary with the form of BN.

Lubricity: Self-lubricating property due to its layered structure, which reduces friction and wear in moving parts.

Non-Toxic: Safe to use in various settings, including medical and food processing industries, due to its non-toxic nature.

High-Temperature Performance: Maintains stability at extremely high temperatures, exceeding 1000°C in inert atmospheres, making it suitable for refractory applications.

(Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications)

Specification of Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications

HBN boron nitride porcelains use special properties for requiring circumstances. This material takes care of severe warmth quite possibly. It stands up to temperature levels over 3000 levels Fahrenheit conveniently. It maintains its stamina and shape under these problems. Lots of steels fall short a lot previously. This makes HBN excellent for components in furnaces or jet engines.

Warmth relocations through HBN efficiently. It conducts warm far better than stainless-steel. This aids pull warmth away from crucial components. So points run cooler and last longer. It protects against overheating problems in electronics or power systems.

HBN is additionally a solid electrical insulator. Power does not stream via it quickly. This is vital for components needing electrical seclusion. It works accurately in high-voltage settings. It keeps delicate electronic devices safe from roaming currents.

The product imitates a strong lubricating substance as well. Its layers slide over each other smoothly. This decreases rubbing substantially. Moving components experience less wear. It works well in vacuum or high heat where oils fail. Bearings and seals profit greatly.

HBN ceramics resist chemical assault strongly. Acids and bases don’t harm them conveniently. Molten steels also don’t adhere to them. This provides excellent corrosion defense. Components remain cleaner and last much longer in harsh chemical procedures.

It machines fairly well for a ceramic. You can form it precisely making use of conventional devices. This permits complicated part designs. Manufacturing costs stay reduced as a result of easier machining. Facility forms for aerospace or semiconductor devices come to be sensible.

HBN ceramics are light-weight compared to metals. This conserves weight in relocating systems. It assists boost performance and efficiency. Much less weight indicates much less energy required for operation. Applications like aerospace value this greatly.

The surface of HBN denies sticking. Molten products slide right off. This avoids build-up throughout casting or steel handling. Clean-up is easier and downtime lowers. Production lines run smoother with much less upkeep.

(Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications)

Applications of Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications

HBN boron nitride porcelains unlock remarkable opportunities for requiring usages. Their unique buildings make them valuable across numerous markets. Electronics greatly depend on them. They keep things cool efficiently. This protects against overheating in vital parts. They act as excellent electric insulators as well. This is important for risk-free procedure. HBN components handle warmth in power electronic devices and LED systems. They make sure secure efficiency.

The aerospace field requires products that hold up against extreme warm. HBN ceramics succeed below. They maintain toughness at extremely heats. They stand up to thermal shock very well. Abrupt temperature level modifications do not split them. They serve accurately in rocket nozzles and thermal protection systems. Their stability is crucial.

Metal casting and glassmaking advantage substantially. HBN ceramics are outstanding release agents. Molten steel and warm glass don’t adhere to them. This makes demolding easier. It boosts surface area coating on cast components. Crucibles and mold and mildews last much longer. Manufacturing costs drop. Product high quality rises.

Cosmetics utilize HBN powder extensively. It offers a smooth, smooth feel. It helps spread items evenly on skin. It adds a refined shine. You locate it in structures, lipsticks, and eye makeup. It improves structure and application.

Semiconductor making needs ultra-pure materials. HBN ceramics fulfill this need. They supply exceptional chemical pureness. They stand up to rust from harsh chemicals. Crucibles for growing crystals are a vital application. They ensure high-purity silicon and other semiconductors. HBN elements are necessary for advanced chip manufacturing.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications

What makes HBN ceramics different for tough jobs?

HBN ceramics handle extreme heat incredibly well. They stay stable and strong even when things get really hot. This is vital for parts near furnaces or rocket engines. They also resist chemical attacks from molten metals or harsh gases. This combination is hard to find in other materials.

How good is HBN at moving heat?

HBN moves heat away very effectively along its surface layers. This stops hot spots from forming. It keeps sensitive electronics or tools cooler. This heat spreading is crucial for making things last longer under stress. Think semiconductor tools or high-power electronics needing reliable cooling.

Does HBN conduct electricity?

No. HBN is an excellent electrical insulator. This is key even when it gets very hot. Many good heat spreaders also conduct electricity, which causes problems. HBN insulates reliably. This makes it safe around high voltages or delicate circuits needing electrical isolation.

Is HBN easy to work with?

Yes. HBN is naturally slippery and relatively soft for a ceramic. Machining it into precise shapes is simpler than with harder ceramics like alumina. This saves time and cost during manufacturing. Complex parts like crucibles, nozzles, or insulators are easier to produce accurately.

Why choose HBN over other options?

HBN solves multiple problems at once. It handles extreme heat, spreads heat fast, blocks electricity, and resists chemicals. It’s also easier to machine than many alternatives. This unique mix cuts costs long-term. It improves performance and reliability in demanding applications like aerospace, electronics, and metal processing.

(Unlocking The Potential of Hbn Boron Nitride Ceramics for High-Performance Applications)

REQUEST A QUOTE

RELATED PRODUCTS

Customized Industry Usage High Temperature Resistant Bn Boron Nitride Ceramic

Low Thermal Expansion Boron Nitride Ceramic Parts

High Precision Insulation Boron Nitride Composite Ceramic Bnsz

Professional Manufacture Large Size Boron Nitride Ceramic Tubes

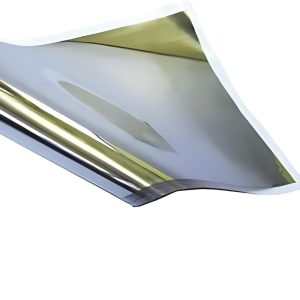

Chemically Stable Boron Nitride Ceramic BN Film