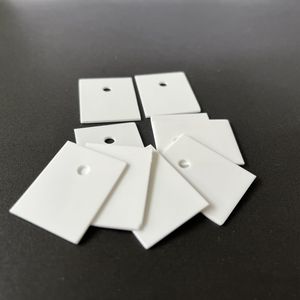

Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel)

Specifications of 100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel

The 100/115/125mm Vacuum Brazed Diamond Triangle Star Grinding Cup Wheel matches marble, ceramic, quartz rock, and steel surface areas. The wheel’s vacuum brazing modern technology bonds ruby particles to the steel core. This process guarantees strong attachment. It improves longevity. The wheel stands up to wear throughout hefty use. The ruby sections feature a triangle star style. This pattern increases grinding performance. It lowers blocking. Particles gets rid of promptly during job. The mug wheel operates at broadband. Warmth accumulation remains low. The vacuum brazed structure prevents segment loss. Performance remains secure gradually.

3 dimensions (100mm, 115mm, 125mm) in shape basic angle mills. Customers change between products without transforming devices. The wheel’s fractional rim supplies aggressive material elimination. It handles rough grinding and great ending up. The ruby grit concentration is enhanced. It balances reducing rate and long life. The steel body includes enhanced joints. Resonance reduces during procedure. Control boosts. Safety dangers lower.

The mug wheel works completely dry or damp. Water usage expands life expectancy. It decreases dirt. The vacuum brazed rubies remain sharp. Smooth outcomes require less initiative. Breaking or fracturing risks lower on brittle products like ceramic. The wheel’s lightweight style decreases individual fatigue. Jobs surface faster.

Professional contractors and do it yourself customers pick this wheel for versatility. It adapts to concrete, granite, and crafted rock. The triangle celebrity sections produce constant grooves. Surface area prep work for adhesives or layers becomes reliable. Storage is straightforward. The wheel withstands corrosion. Maintenance stays very little.

Purchase consists of a compatibility talk to your mill’s power and RPM. Proper use ensures maximum life expectancy. Stay clear of overheating. Comply with security standards for disc mounting. Put on protective equipment during procedure. The wheel satisfies sector standards for abrasives. It uses affordable product elimination. Repetitive tasks see boosted results. Time and labor prices decline.

The product ships with a guarantee against producing issues. Customer support assists with use inquiries. Mass orders receive discounted rates. Shipment times vary by region. Inspect availability before purchase. Regional guidelines may request specialist use. Evaluate the wheel on a little location initially. Validate efficiency suits assumptions. Adjust stress or rate as required. Change the wheel when sections put on down. Consistent performance counts on prompt substitute.

(100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel)

Applications of 100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel

The 100/115/125mm vacuum cleaner brazed diamond triangle star grinding cup wheel deals with tough materials like marble, ceramic, quartz rock, and steel. Its vacuum cleaner brazed ruby sectors stay sharp much longer. This device benefits grinding, smoothing, and forming surfaces. Specialists in building, rock fabrication, and renovation depend on it for constant results. The style decreases warm accumulation throughout usage. This prevents damages to both the tool and the workpiece.

The cup wheel fits angle mills commonly located in workshops. The 100mm size fits tight rooms and thorough tasks. The 115mm version balances rate and control for general-purpose work. The 125mm alternative removes material faster on huge surfaces. All sizes reduced easily without breaking breakable materials like ceramic tiles. The diamond grit distribution makes certain also wear. This prolongs the wheel’s life-span compared to common abrasive discs.

Concrete professionals utilize it to level irregular floors or gloss countertops. Stone makers smooth harsh sides on slabs. Metalworkers grind welds on steel surfaces. DIY lovers take on home projects like improving stone pavers. The wheel operates dry or damp. Water air conditioning minimizes dust in interior setups. The vacuum cleaner brazing approach bonds diamonds firmly to the steel core. This avoids sections from removing under high pressure.

The triangular celebrity segment pattern boosts particles clearance. This maintains the wheel from clogging throughout heavy use. Aggressive grinding remains effective without constant stops. The cup form supplies stability on tilted surface areas. Individuals preserve control also at high speeds. Constantly put on safety goggles and handwear covers. Protect the workpiece before beginning. Check the mill’s RPM matches the wheel’s rating.

Various products need differing pressure and speed. Examination on a scrap item initially. Clean the wheel on a regular basis to eliminate embedded fragments. Shop it in a dry area to prevent rust. Replace the wheel if sections reveal substantial wear or fractures.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel

What materials can this grinding cup wheel handle?

The 100/115/125mm Vacuum Brazed Diamond Grinding Cup Wheel works on marble, ceramic, quartz stone, steel. It grinds, smooths, shapes surfaces. Vacuum brazing bonds diamonds tightly. This allows fast material removal. It works dry or wet. Professionals use it in construction, stonework, metal jobs.

Why choose vacuum brazing over other methods?

Vacuum brazing fixes diamonds to the wheel base using high heat in a vacuum. This creates stronger bonds than sintering or electroplating. More diamonds stay attached during grinding. The wheel lasts longer. It cuts faster with less vibration. Performance stays steady under heavy use.

Can this wheel handle concrete?

No. This wheel focuses on harder materials like marble, ceramic, quartz, steel. Concrete contains aggregates. These cause uneven wear. Use a sintered or segmented diamond wheel for concrete. This wheel’s design targets precision on dense surfaces.

How long does the wheel last?

Lifespan depends on material hardness, pressure, usage frequency. Proper use on recommended materials gives 80-120 hours of grinding. Avoid overheating. Clean debris regularly. Check for diamond exposure. Replace when cutting speed drops or vibrations increase.

What safety steps should I follow?

Wear goggles, gloves, a mask. Secure the workpiece. Ensure the tool’s RPM matches the wheel’s rating. Start grinding at a low angle. Increase pressure gradually. Let the wheel cool if it overheats. Inspect for cracks or damage before each use. Store in a dry place.

(100/115/125mm Vacuum Brazed Diamond Triangle Star Marble Ceramic Quartz Stone Steel Grinding Cup Wheel)

REQUEST A QUOTE

RELATED PRODUCTS

Basair Granite Line Polishing Machine for Stone/Granite/Quartz/Ceramic/Porcelain in China Polangiz Poleringsmaskin

Clear High Quality Quartz Glass Plates Polished Fused Silica Glass Sheet

Factory Supply Whole Mug Ceramic Heating Element Quartz Ceramics

Factory Custom Heat Resistant Alumina Ceramic Crucible Large Silica Opaque Quartz Crucible

Good Quality Durable Quartz Coal Grinding Ball Mill , Cement Ceramic Industrial Dry Ball Mill Grinding Machine