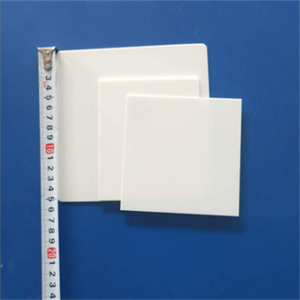

Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube)

Specifications of 1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube

The 1200C Single Zone Ceramic Sintering Powder Laboratory Tube Muffle Heater helps high-temperature applications. It handles ceramic sintering, powder processing, and product testing. The heating system gets to a maximum temperature level of 1200 ° C. The heating zone utilizes a 100mm diameter quartz tube. The quartz tube resists thermal shock. It ensures constant warmth distribution. The tube fits examples up to 300-600mm in size. The furnace warms up rapidly. It maintains secure temperatures for specific experiments.

The heating element uses silicon carbide rods. These rods provide fast warmth generation. They ensure long service life. The furnace chamber is made from alumina ceramic fiber. This product offers superb insulation. It lowers energy consumption. The external shell is steel. It secures inner elements. The framework continues to be awesome during operation.

Temperature level control relies on a programmable digital controller. The controller sustains several home heating programs. Users established temperature ramps and hold times. The system consists of a K-type thermocouple. It keeps an eye on temperature precisely. Over-temperature defense stops damage. The furnace shuts down automatically if limits surpass.

The device operates on 120V or 220V power. Power usage is 3kW. Setup suits basic lab electrical outlets. The small style conserves room. The front panel includes a clear screen. Buttons enable very easy changes. Safety and security features consist of a circuit breaker. The door stays secured during heating.

This heating system refines ceramics, steels, and composites. Applications include annealing, calcination, and binder fatigue. It helps research study or small production. The quartz tube permits gas inlet links. Users present inert or reactive ambiences. Optional cooling systems quicken cooldown.

Maintenance is simple. The heating chamber withstands chemical deterioration. The quartz tube cleans easily. Substitutes are readily available. Devices include crucibles, watercrafts, and example owners. Technical assistance helps with configuration. Service warranty covers one year for components.

(1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube)

Applications of 1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube

The 1200C Solitary Area Ceramic Sintering Powder Laboratory Tube Muffle Furnace with a 100mm Quartz Tube offers multiple duties in research and commercial setups. This heating system handles high-temperature processes up to 1200 ° C. It helps products testing, ceramic sintering, and warm therapy of steels. The design includes a quartz tube with a 100mm diameter. This allows very easy insertion and removal of examples. The quartz product stands up to thermal shock. It additionally guarantees visibility throughout experiments.

The heating system fits laboratories concentrated on product scientific research. It supports explores ceramics, glass, and composites. The solitary home heating area supplies uniform temperature level distribution. This is crucial for consistent sintering results. Users can control home heating prices exactly. The digital user interface streamlines temperature level modifications. Safety attributes include overheat security. The insulation lessens warmth loss. This boosts energy effectiveness.

Industrial applications consist of screening finishings and alloys. The quartz tube protects against contamination throughout responses. It works well for annealing steel parts. Scientists utilize it for catalyst researches. The furnace fits tiny batches of powder examples. It is portable sufficient for benchtop arrangements. The structure uses resilient ceramic fiber. This guarantees long-lasting performance under repeated home heating cycles.

Academic labs gain from its versatility. Pupils can research stage transitions in products. The furnace help in synthesizing innovative ceramics. It is compatible with inert or responsive environments. Gas inlet ports permit controlled environments. This is needed for oxidation or reduction experiments. Maintenance is uncomplicated. The burner are very easy to replace.

This version meets strict research laboratory criteria. It stabilizes cost with accuracy. The temperature uniformity remains within ± 1 ° C. Quick ramp rates conserve time throughout experiments. Individuals can program numerous home heating phases. The furnace is optimal for prototyping new materials. Industries like aerospace and electronic devices count on its integrity. The robust building decreases downtime. Technical support ensures smooth operation.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube

What is the maximum temperature this furnace can reach? The furnace heats up to 1200°C. This suits processes like ceramic sintering, powder treatments, or metal heat-tests. The temperature stays stable during operation. The system uses advanced controls for precise adjustments.

Why does the furnace include a 100mm quartz tube? The quartz tube handles high temperatures without cracking. Its 100mm diameter fits most lab samples or small batches. Quartz resists thermal shock better than other materials. Users can replace the tube if damaged. Always check the tube’s condition before heating.

Is the furnace safe for long runs? Safety features prevent overheating. The furnace auto-shuts off if temperatures exceed limits. The outer casing stays cool even at max heat. Ceramic insulation reduces heat loss. Always place the furnace on a non-flammable surface. Keep flammable items away during use.

How do I install the quartz tube correctly? Align the tube with the furnace’s heating zone. Secure both ends with supplied brackets. Ensure no gaps exist between the tube and heating elements. Follow the manual’s step-by-step guide. Contact support if alignment issues persist. Never force the tube into place.

What maintenance does the furnace need? Clean the chamber after each use to remove residue. Inspect the quartz tube for cracks or discoloration monthly. Check wiring connections for looseness or wear. Avoid sudden temperature changes to extend component life. Schedule professional servicing yearly for calibration. Store the furnace in a dry area when unused.

(1200c Single Zone Ceramic Sintering Powder Lab Tube Muffle Furnace With 100mm Quartz Tube)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality the Frosted Ceramic Quartz Crucible Which Melts and Melts Gold and Silver Evaporating Dish

Zhuodi New Automatic Ceramic Tile Marble Quartz Stone Pressing Forming Machine Key Including Motor Pump Manufacturing Plants

Double-Lamp Three-Hole Ceramic and Glass Condenser Cavity Reflector for Laser Devices Quartz Tubes Product Category

Quartz ./silica Sand Grinding Machine -Ceramic Ball Mill Classigfying Production Line

China Whole White Quartz Stone Veneer 3200*1600*30mm Quartz Stone Cabinets Quartz Stone Powder