Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

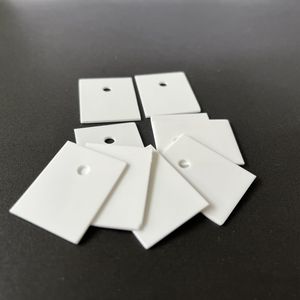

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products)

Specifications of 99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products

99.99% High-Grade Quartz sets the criteria for purity in commercial and manufacturing applications. This premium material consists of 99.99% silicon dioxide (SiO2), ensuring unmatched uniformity for precision-driven industries. The ultra-low impurity profile– listed below 0.01% for trace elements like iron, aluminum, and titanium– makes it optimal for high-tech usages. Semiconductor producing relies upon it for silicon wafer production. Optical devices utilizes it for lenses and prisms as a result of its quality. Laboratories rely on its inert homes for chemical-resistant devices.

The raw quartz undertakes strenuous processing. Advanced filtration techniques remove pollutants. High-temperature refining guarantees architectural stability. The outcome is a homogenous product without splits, bubbles, or incorporations. Granules and powders can be found in customizable dimensions. Great powders match microelectronics. Coarse grains help high-durability surfaces.

Thermal security is a key benefit. It holds up against temperatures as much as 1,650 ° C without deformation. This makes it best for heater components or aerospace components. Chemical inertness enables use in harsh atmospheres. Acidic or alkaline problems trigger no destruction. Electrical insulation buildings meet stringent industry standards.

Quality control consists of X-ray fluorescence screening. Every set validates SiO2 material. Laser fragment analyzers confirm grain dimension circulation. Moisture degrees remain below 0.02% to stop clumping. Packaging utilizes moisture-resistant, vacuum-sealed bags. Mass orders ship in reinforced containers to prevent damages.

Lower-grade quartz often falls short under severe anxiety. Pollutants trigger defects in semiconductor wafers. Inconsistent thermal development dangers equipment failing. This product removes such problems. Performance stays trustworthy also in long-lasting use.

High-end industries utilize it for premium surfaces. Countertops and attractive items acquire resilience and aesthetic charm. Very little upkeep is needed. Staining or scraping hardly ever happens.

Consumers receive technical assistance for application-specific demands. Customized mixes adapt to unique task requirements. Preparations are short for immediate orders. International logistics ensure prompt distribution.

The item satisfies ISO 9001 and ASTM E11 criteria. Certifications are readily available upon request. Safety and security data sheets detail handling procedures. No unsafe discharges happen throughout processing or use.

Buying 99.99% High-Grade Quartz guarantees performance and decreased waste. Operational prices drop as a result of less replacements. Result top quality boosts throughout sectors.

(99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products)

Applications of 99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products

Applications of 99.99% High-Grade Quartz: The Gold Requirement in Pureness Costs Quartz Products

99.99% top-quality quartz is the purest form of quartz available. This product is vital for markets requiring unequaled precision and dependability. Its near-perfect purity makes it optimal for advanced modern technology and high-performance applications.

In electronic devices, this quartz is crucial. Semiconductor producing depends on it for silicon wafer manufacturing. The pureness guarantees marginal contaminations, boosting chip performance and device longevity. Quartz crucibles made from this material handle severe temperature levels throughout silicon melting. They stop contamination, maintaining the integrity of digital components.

The optics sector advantages substantially. Top-quality quartz is made use of for lenses, prisms, and UV illumination systems. Its transparency to ultraviolet light makes it best for clinical tools and medical gadgets. Lasers and telescopes make use of quartz elements for quality and sturdiness. Also small contaminations can misshape optical efficiency, so 99.99% pureness is non-negotiable.

Industrial making usages this quartz for high-temperature procedures. It resists thermal shock and chemical corrosion, making it optimal for heating system tubes and laboratory devices. In chemical production, quartz activators guarantee reactions occur without interference from contaminants. This purity degree extends tools life expectancy and lowers downtime.

Solar power systems rely on high-purity quartz for photovoltaic panels. The product converts sunshine to electrical energy efficiently. Contaminations reduced energy outcome, so 99.99% quartz optimizes performance. This integrity supports lasting power remedies globally.

Scientific research requires precision devices. Quartz with 99.99% pureness is utilized in logical tools like spectrometers and chromatographs. Exact measurements hinge on material consistency. Even trace impurities can skew results, taking the chance of data stability.

Costs quartz items meet rigorous high quality criteria. Qualifications like ISO make certain conformity with commercial and environmental guidelines. Makers trust this quartz for critical applications where failing is not an alternative.

The need for top-quality quartz expands as innovation advances. Industries focus on materials that enhance efficiency and reduce dangers. 99.99% quartz remains unparalleled for purity, performance, and flexibility. Its role in advancement covers electronic devices, power, scientific research, and beyond.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of 99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products

What is 99.99% High-Grade Quartz?

This quartz is nearly pure. It contains 99.99% silicon dioxide. Other quartz products have more impurities. This level of purity makes it ideal for precision tasks.

Where is 99.99% High-Grade Quartz used?

It works in high-tech industries. Semiconductors, solar panels, and lab equipment rely on it. Its stability under extreme conditions matters. Heat, pressure, or chemicals rarely affect it.

Why choose this over lower-grade quartz?

Higher purity means better performance. It resists cracks, discoloration, and chemical damage longer. Products last more. Maintenance costs drop. Industries needing accuracy trust it.

Is it safe for daily or industrial use?

Yes. It meets strict safety standards. No harmful substances leak. Still, handle it carefully. Wear gloves and masks when cutting or grinding. Dust can irritate lungs.

Why call it the “Gold Standard” in purity?

The 99.99% mark is rare. Most quartz products hit 99.9% or lower. That extra 0.09% reduces flaws. It sets a benchmark others aim for. Labs and manufacturers prefer it. Consistency matters. Results stay reliable.

(99.99% High-Grade Quartz the Gold Standard in Purity Premium Quartz Products)

REQUEST A QUOTE

RELATED PRODUCTS

Customizable Size Long Life Casting Quartz Ceramic Crucible for Dental Lab

Book Matched Marble Calacutta Type White Quartz Countertops Stone Slab Manufacturing For Quartz Kitchen Stone Benchtops

Ceramic Silica Quartz Crucible Bowl for Melt Gold Silver Copper Platinum Jewelry Tool with Metal Boat Pot

Ceramic Crucible High Purity 2500 G High Temperature Resistance Gold Melting Crucible Melting Metal Quartz Bowl

Foshan Display Shelf Chest of Drawers Shop Tile Quartz Stone Floor Stand Displays Ceramic Tile Display Cabinet