Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

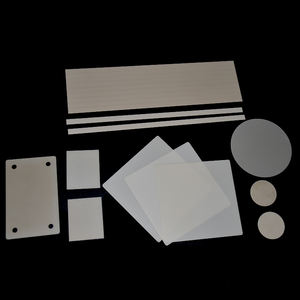

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop)

Specifications of Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop

The Bridge Saw Kind CNC Stone Cutting Maker is designed for cutting marble, granite, and quartz into kitchen area countertops. It supplies high precision and performance for commercial applications. The maker takes care of slabs as much as 3200mm in length, 2000mm in size, and 120mm in thickness. This makes it ideal for large projects. The diamond blade determines 700mm in size. It turns at 1500 RPM for fast, smooth cuts. A water air conditioning system maintains the blade temperature low. This minimizes dust and extends blade life.

The electric motor supplies 15HP power. It ensures regular performance under hefty work. The CNC system enables automated procedure. Users can post digital designs directly. The software program supports formats like DXF and DWG. Operators input dimensions making use of a control panel. Modifications are quick and exact.

Laser overviews help position pieces properly. Sensors monitor cutting deepness in real time. This minimizes product waste. The maker deals with marble, granite, quartz, and similar rocks. It adapts to different hardness degrees. Security functions include an emergency situation quit button. Protective guards cover moving parts. The style avoids accidental contact with the blade.

The frame is constructed from reinforced steel. Trick components use anti-corrosion layers. This makes certain long-lasting sturdiness. Upkeep calls for minimal effort. Gain access to panels allow customers reach internal components quickly. Regular cleansing prevents debris buildup. Technical support is offered for troubleshooting. Extra parts can be ordered online.

The machine fits manufacturing facilities and workshops. It speeds up manufacturing without giving up quality. Training is offered brand-new drivers. Personalized setups conserve time on repetitive tasks. Energy-saving settings reduce power intake. Sound levels remain low during operation.

(Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop)

Applications of Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop

The Bridge Saw Kind CNC Rock Cutting Machine is made for accuracy cutting of marble, granite, and quartz. It is commonly utilized in developing kitchen countertops. The equipment manages large stone pieces successfully. It guarantees clean cuts with marginal material waste. This makes it suitable for high-volume production.

The machine cuts kitchen counters to precise shapes and sizes. It processes straight edges, bent designs, and facility patterns. This versatility fits modern-day kitchen styles. The blade readjusts automatically for different materials. Granite requires a slower reducing speed. Marble needs a finer blade. The CNC system takes care of these adjustments without hands-on input.

Custom-made forms like sinks, faucet openings, and water drainage grooves are conveniently accomplished. The equipment reviews digital layouts straight from CAD data. This reduces mistakes in measurement. Operators can configure the maker for repetitive jobs. Batch manufacturing becomes faster and much more regular.

The Bridge Saw Kind CNC is also made use of for vanity tops, wall panels, and flooring floor tiles. Its vacuum cleaner table holds slabs strongly during reducing. This protects against shifts or vibrations. The result is smooth sides and accurate angles. Water cooling systems maintain the blade and material from overheating. Dust and particles are reduced throughout operation.

Dining establishments, hotels, and property tasks rely upon this equipment for durable surfaces. Quartz counter tops obtain popularity for their reduced maintenance. The maker handles quartz’s firmness without breaking. Its diamond-tipped blades remain sharp longer. Maintenance expenses remain low gradually.

Operators regulate the device through an easy interface. Training new customers takes little time. Safety and security attributes include emergency quits and protective covers. Production downtime is decreased. The equipment functions continuously for hours. Power intake continues to be effective.

Services benefit from faster turn-around times. Personalized orders are completed within limited target dates. Product waste is minimized by up to 20%. Profit margins enhance. Clients get top quality products regularly. The equipment’s toughness ensures long-term use. Preliminary financial investment expenses are offset by efficiency gains.

This modern technology fulfills the demands of modern-day stone manufacture. It integrates rate, precision, and integrity. Little workshops and huge factories both discover it crucial. The focus stays on supplying perfect surfaces for every job.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop

What is a Bridge Saw Type CNC Stone Cutting Machine?

This machine cuts stone materials like marble, granite, or quartz. It uses CNC technology for precise control. A diamond blade moves along a bridge structure. It handles large slabs smoothly. The design suits kitchen countertop production. Custom shapes and sizes are achievable.

How accurate is the machine?

CNC systems ensure high precision. Cuts stay within 0.5mm tolerance. Computer-guided movements reduce human error. Blades maintain sharpness for clean edges. Repeat jobs produce identical pieces. Software updates improve accuracy over time.

Can it cut different materials like marble, granite, and quartz?

Yes. The machine works on all three materials. Diamond blades handle varying hardness levels. Adjust speed and pressure settings for each stone type. Granite requires slower cutting speeds. Quartz needs careful handling to avoid cracks.

What safety features does the machine include?

Emergency stop buttons are installed. Blade guards protect operators from debris. Sensors detect abnormal vibrations or blockages. Automatic shutdown prevents overheating. Safety shields cover moving parts. Training ensures proper use.

How often does the machine need maintenance?

Clean debris after each use. Lubricate rails weekly. Check blade alignment monthly. Replace worn blades every 6-12 months. Inspect coolant systems regularly. Professional servicing is recommended yearly.

(Bridge Saw Type Cnc Stone Cutting Machine for Marble Granite Quartz Kitchen Countertop)

REQUEST A QUOTE

RELATED PRODUCTS

Marble Ceramic Quartz Vacuum Brazed Profiling Wheels With Metal Bonding Agent for Deburring Applications Premium Grinding Wheels

Custom Logo Stone Quartz Tower Display Stand Tile Showroom Displays Rack Marble Granite Mosaic Glass Metal Display Shelf

High Purity Quartz Products for Advanced Manufacturing

Foshan Display Shelf Chest of Drawers Shop Tile Quartz Stone Floor Stand Displays Ceramic Tile Display Cabinet

Milky Big Size Quartz Glass Sand Blasted Cylindrical Lab Crucible