Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

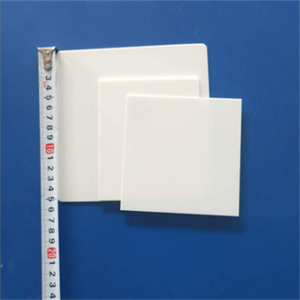

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine)

Specifications of CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine

The CNC developed terrazzo porcelain piece cutting maker processes marble-look Calacatta quartz rock pieces with accuracy. It makes use of advanced CNC innovation to ensure accuracy in cutting, forming, and describing. The equipment takes care of products approximately 3200mm in length, 1800mm in size, and 80mm in thickness. Its high-power pin operates at rates between 6000-24000 RPM, enabling smooth cuts on hard surface areas like quartz and porcelain.

The system includes a diamond-tipped blade for clean sides. The device reduces product waste through enhanced cutting courses. An automatic lubrication system keeps components running smoothly. Operators control settings through an user-friendly touchscreen interface. Preloaded templates streamline typical cutting tasks.

Dust collection ports attach to exterior systems to keep a clean work area. Safety and security functions include emergency stop switches, safety covers, and overload alerts. The machine collaborates with CAD/CAM software program for custom styles. File styles like DXF and DWG are compatible.

The electric motor delivers 15 kW for regular efficiency under heavy lots. Heavy-duty steel structures ensure security throughout procedure. Adjustable clamps safe pieces in place. Laser guides help line up materials accurately. Error detection software application decreases blunders.

This machine fits factories creating kitchen counters, floor covering, or wall panels. It deals with terrazzo, porcelain, and quartz pieces with marble patterns. Maintenance needs are low due to durable elements. Technical assistance consists of remote diagnostics and on-site service. A 2-year service warranty covers components and labor.

Training programs teach operators to utilize the software application and hardware effectively. Customizable settings adjust to different manufacturing needs. Energy-efficient motors reduce power consumption. Water-cooling systems protect against overheating throughout expanded usage. The maker fulfills worldwide safety and security standards for industrial tools.

(CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine)

Applications of CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine

The CNC honed terrazzo porcelain slab marble look Calacatta quartz rock piece cutting maker is made for precision cutting in building and construction and interior design. It deals with materials like terrazzo, porcelain, marble-effect quartz, and similar surface areas. The device suits kitchen counters, floor covering, wall cladding, and ornamental items. Its advanced CNC technology guarantees accurate cuts for complex shapes and patterns. Individuals conserve time and lower product waste with constant outcomes.

The equipment deals with multiple piece sizes and thicknesses. It adapts to customized designs for property and commercial tasks. Engineers and fabricators use it to develop seamless setups. The automatic system decreases human mistake. Operators input designs through software program, and the maker carries out cuts swiftly. This speeds up manufacturing without sacrificing top quality.

Dirt control features keep workspaces tidy throughout operation. The enclosed cutting location and suction systems secure employees from particles. Safety systems like emergency situation stops and blade guards stop crashes. Maintenance is simple as a result of sturdy elements and easy-access components.

The maker’s adaptability makes it perfect for reproducing premium marble checks out reduced expenses. It produces realistic veining and appearances on quartz pieces. Customers attain deluxe visual appeals without all-natural stone expenditures. The honed surface includes a smooth, matte look prominent in modern designs.

Businesses benefit from enhanced performance and lowered labor prices. The equipment handles large orders dependably. It meets need for tailored stone products in cooking areas, bathrooms, and lobbies. Its compatibility with various products permits diverse project applications.

The straightforward interface requires marginal training. Updates and repairing guides sustain smooth procedure. Manufacturers focus on sturdiness to endure hefty usage. The maker’s precision guarantees limited resistances for best installations. It sustains innovative liberty while preserving industrial-grade performance.

Integrity and adaptability make the device an essential device for rock manufacture. It fulfills the requirements of small workshops and big factories. The technology bridges style vision and practical implementation. Customers provide high-grade results continually.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine

What materials can this machine cut? The CNC honed terrazzo porcelain slab marble look Calacatta quartz stone slab cutting machine handles terrazzo porcelain, marble-effect slabs, Calacatta quartz, granite, ceramic, and similar hard materials. The machine’s diamond-tipped blades and high-speed spindle ensure clean cuts without chipping. It adapts to varying thicknesses from 3mm to 50mm.

How precise is the cutting accuracy? The machine delivers precision within ±0.1mm. Advanced CNC software controls blade speed and movement. Laser guides align slabs correctly. This eliminates errors in complex shapes or angled cuts. Operators achieve smooth edges consistently.

What maintenance does the machine require? Clean debris from the cutting area daily. Lubricate rails and bearings weekly. Check blade sharpness monthly. Replace worn blades immediately. Update CNC software regularly. Proper maintenance extends the machine’s lifespan.

Can beginners operate this machine easily? Training is provided for new users. The interface uses simple icons and menus. Pre-programmed settings handle common cuts. Manual overrides allow adjustments. Most operators learn basic functions in one day. Technical support is available for troubleshooting.

What safety features are included? Emergency stop buttons are placed on all sides. Protective shields cover moving parts. Sensors detect abnormal vibrations or overheating. The machine shuts down automatically if issues arise. Safety goggles and gloves are recommended during operation.

The machine works for countertops, flooring, wall panels, and custom designs. It supports batch processing for large projects. Dust collection systems keep workspaces clean. Energy-efficient motors reduce power consumption. Custom blade configurations are available for specialty materials.

The machine suits small workshops and industrial factories. Noise levels stay below 85 decibels. Installation requires a stable floor and three-phase power supply. Warranty covers parts and labor for two years. Extended service plans include priority repairs.

Technical specifications are adjustable based on user needs. Demo sessions can be arranged before purchase. Payment options include leasing or installment plans. Shipping is global with onsite assembly support. Spare parts are stocked for quick replacements.

(CNC Honed Terrazzo Porcelain Slab Marble Look Calacatta Quartz Stone Slab Cutting Machine)

REQUEST A QUOTE

RELATED PRODUCTS

Whole CE Certified Cnc Granite Machine Water Jet Cutting Machine for Quartz Plates and Large Ceramic Tiles

Whole Nano Quartz Powder for Wafer Fabrication and Foundry High Quality Silica Flour for Glass Factory

Custom Quartz Stone Display Tower Rack Tile Sample Display Stand for Wood Products with Silk-screen logo

The beauty of quartz shines through in your kitchen in 2025

Best-ing Black Quartz Stone With Double Bowl for Household Kitchen