Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

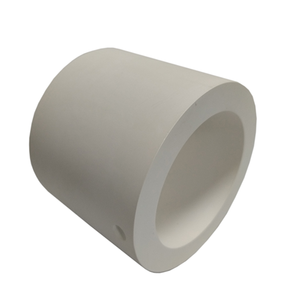

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder )

Specifications of Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder

Manufacturing Facility Straight Supply Quartz Powder Quartz Sand Silica Quartz Powder is created for commercial applications calling for high pureness and uniformity. The item consists of over 99.5% silicon dioxide (SiO2), making sure marginal impurities. Fragment dimensions vary from coarse granules to fine powders, with mesh alternatives like 200, 300, and 400 offered. This adaptability matches varied needs across markets.

The material is sourced from costs quartz deposits and processed making use of electric arc furnaces and progressed milling innovations. These approaches boost pureness and control fragment circulation. Rigorous top quality checks are performed at every stage, from resources choice to last product packaging. Examining includes X-ray fluorescence (XRF) for chemical structure and laser diffraction for bit size accuracy.

Applications cover building and construction, glass manufacturing, ceramics, paints, layers, and electronics. In construction, it reinforces concrete and improves durability. Glass producers depend on its high silica content for clearness and thermal resistance. Ceramic suppliers utilize it to improve product hardness and heat stability. Paints and finishes take advantage of its chemical inertness and UV resistance. Electronics applications include semiconductor production and epoxy molding compounds.

Factory-direct sourcing cuts middleman prices, providing competitive pricing without jeopardizing top quality. Bulk orders are supported with scalable supply options. Product packaging choices include 25-kilogram woven bags, 1-ton big bags, and customized arrangements. Moisture-resistant materials make certain product stability throughout storage and transit.

Customization is available for particle dimension circulation, purity degrees, and packaging. Technical assistance aids in selecting specs matching certain project requirements. Logistics networks guarantee timely shipment to international locations. Strict adherence to global criteria like ISO and ASTM makes sure reliability. The item satisfies environmental and safety guidelines, making it suitable for lasting manufacturing methods.

(Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder )

Applications of Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder

Manufacturing facility straight supply quartz powder, quartz sand, silica, and quartz powder offer numerous markets. These materials are crucial for building. Home builders mix quartz sand right into concrete. This makes frameworks more powerful. Quartz powder is added to ceramics. It enhances heat resistance. These uses aid structures last much longer. Glass manufacturing relies on high-purity silica. It forms the base product for glass products. This consists of windows, containers, and optical fibers. The electronic devices market requires ultra-pure quartz powder. It is utilized in semiconductors and microchips. These parts power gadgets like smart devices and computers.

The ceramics sector gain from quartz items. They are mixed right into tiles, tableware, and sanitaryware. This enhances longevity and surface area coating. Paints and coatings utilize silica as a filler. It improves structure and resistance to weathering. Chemical plants procedure quartz powder right into silicon substances. These are utilized in adhesives, sealers, and lubes.

Water therapy systems use quartz sand as a filter medium. It catches pollutants in alcohol consumption water and wastewater. This ensures cleaner result. Metallurgy applications consist of mold and mildews and refractory products. Quartz sand endures heats in metal spreading. Factories depend on it for accuracy.

The oil and gas sector uses silica in hydraulic fracturing. It props open rock fissures to draw out fuel. This increases well performance. Manufacturing facilities supply these materials wholesale. This reduces expenses for massive jobs. Custom-made grain sizes and purity levels are available. Buyers choose based on their market needs.

Quartz products are chemically inert. They stand up to deterioration and warm. This makes them trusted for harsh atmospheres. Constant quality is made sure through rigorous handling. Raw quartz is cleaned, dried, and ground. Advanced testing types fragments by size. Every batch meets sector standards.

Services sourcing directly from manufacturing facilities save time and money. Middlemen are gotten rid of from the supply chain. This guarantees competitive prices. Dependable delivery routines maintain tasks on course. Technical assistance is usually supplied. Professionals help customers pick the ideal item requirements.

These products are necessary across international markets. Their versatility drives development in production and modern technology. Reliable manufacturing approaches keep them affordable. This supports economic growth in numerous markets.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder

What is quartz powder mainly used for? Quartz powder serves many purposes. It is common in construction materials like concrete and cement. It strengthens these materials. It is also used in ceramics, glass production, and electronics. Its heat resistance and durability make it ideal for industrial applications.

How is quartz sand different from silica sand? Quartz sand and silica sand are similar. Both contain silicon dioxide. The difference lies in purity and texture. Quartz sand has higher purity, often above 99% silica. Silica sand may contain more impurities. Quartz sand particles are usually more uniform in size.

What particle sizes are available for quartz powder? Quartz powder comes in various sizes. Fine grades range from 200 mesh to 500 mesh. Coarser options go up to 10 mm. Sizes depend on the application. Fine powder suits paints and coatings. Coarser grains work better for filtration or abrasives.

Does your quartz powder meet industry standards? Yes. Our quartz powder follows strict quality guidelines. It has over 99.5% SiO2 content. We test for chemical consistency, particle size, and contaminants. Certificates of analysis are provided. This ensures compatibility with global industrial requirements.

Why choose factory-direct quartz products? Buying directly cuts costs. Middlemen add extra fees. We offer competitive pricing without sacrificing quality. Production is closely monitored. Bulk orders are accepted. Custom specifications like particle size or packaging are available. This flexibility meets specific project needs.

(Factory Direct Supply Quartz Powder Quartz Sand Silica Quartz Powder )

REQUEST A QUOTE

RELATED PRODUCTS

Quartz crucible for jewelry casting

Lower Quartz Powder for Industrial Made in India

CNC-4 4 Axis Automatic Marble Granite Ceramic Quartz Bridge Saw with Chamfer Function , Stone Cutting Machine

D18-30mm Fused Silica Laser Protective Lens Quartz Protection Window Optical Laser Machine Lens

Whole High Purity High Quality Fused Quartz Crucible Wear-resistant Arc Crucible