Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

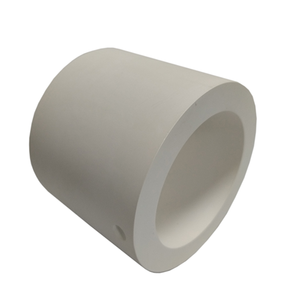

(Fused Silica Quartz Crucible Casting Dish)

Specifications of Fused Silica Quartz Crucible Casting Dish

The Fused Silica Quartz Crucible Spreading Dish is made for high-temperature applications. It works well in laboratories and industrial settings. The material is pure fused silica. This guarantees high thermal stability. The dish takes care of temperature levels up to 1200 ° C. It resists sudden temperature level modifications. This makes it ideal for processes including fast home heating or air conditioning.

The dish has reduced thermal expansion. This maintains its shape under severe warm. It remains chemically inert. Acids and bases do not influence it. This prevents contamination of examples. The surface is smooth. This makes cleaning simple. No deposits stay with it after usage.

The item can be found in numerous dimensions. Common sizes vary from 50mm to 300mm. Personalized sizes are available. The density is consistent. This ensures also warm circulation. The meal is transparent. Individuals can check reactions visually.

It suits melting and casting metals. It works for glass processing. Semiconductor production utilizes it for crystal growth. The dish is resilient. It lasts longer than ceramic options. Very little upkeep is needed. Manage it meticulously to stay clear of mechanical shock.

Safety is a top priority. The material does not release dangerous fumes. It satisfies sector standards for pureness. No additives or binders exist. This ensures constant efficiency.

Storage is straightforward. Keep it completely dry and dust-free. Stay clear of stacking heavy products ahead. Evaluate for fractures prior to each usage. Replace it if damages shows up.

The design focuses on individual convenience. It fits standard lab equipment. No unique tools are needed for handling. It deals with induction heating units and heaters. Compatibility with automated systems is made sure.

Price efficiency is an essential benefit. The lengthy life expectancy reduces substitute frequency. Energy usage remains reduced. Heat transfers successfully. This accelerates procedures.

Performance stays trustworthy in harsh problems. It stands up to oxidation. High-purity applications take advantage of its inertness. Study laboratories and production centers extensively use it. Feedback highlights its stability and ease of use.

Technical support is offered for personalization. Specifications can be readjusted based on needs. Preparations vary by order dimension. Mass orders obtain discount rates. Examples are attended to testing.

The item ships in protective packaging. This stops transit damage. Worldwide delivery choices are supplied. Service warranty covers manufacturing problems. Customer support helps with questions.

(Fused Silica Quartz Crucible Casting Dish)

Applications of Fused Silica Quartz Crucible Casting Dish

Integrated silica quartz crucible casting meals serve numerous duties across various markets as a result of their unique residential or commercial properties. These recipes handle heats well, stand up to thermal shock, and maintain chemical stability. Their main usage remains in steel handling. Shops and metallurgical laboratories rely on them to thaw and cast metals like gold, silver, and platinum. The material’s purity makes sure no contamination, which is important for generating top quality alloys.

The semiconductor industry also depends on these crucibles. They are suitable for expanding single crystals used in electronics. Integrated silica’s low thermal expansion enables constant performance even under quick temperature level changes. This dependability makes the recipes appropriate for processes like chemical vapor deposition, where accuracy issues.

Solar power production gain from these items also. Suppliers utilize them to produce silicon ingots for solar batteries. The crucibles hold up against duplicated home heating and cooling down cycles during crystal growth. Their non-reactive nature maintains the silicon without pollutants, enhancing the effectiveness of the final photovoltaic panels.

In fashion jewelry making, fused silica crucibles are preferred for small casting. Artisans utilize them to develop thorough molds without fretting about product degradation. The smooth surface of the dishes ensures finished items have a tidy, sleek look.

Chemical research laboratories use these recipes for high-temperature reactions. They take care of harsh materials like acids and molten salts without damaging down. This durability reduces substitute costs and downtime in laboratory setups.

Glass and porcelains manufacturing also utilizes integrated silica crucibles. The recipes melt basic materials at severe temperatures while preserving structural integrity. This consistency assists in generating uniform glass or ceramic items.

Integrated silica quartz crucible casting dishes are functional tools. Their warm resistance, pureness, and toughness make them necessary in areas requiring accuracy and dependability. Industries from electronic devices to renewable energy remain to find brand-new applications for these products.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Fused Silica Quartz Crucible Casting Dish

What is a fused silica quartz crucible casting dish? It is a lab tool made of high-purity fused silica. It handles extreme heat. It melts metals, alloys, or other materials. The material resists thermal shock. It stays stable at high temperatures. It works in labs, foundries, or industrial settings.

What temperature can it withstand? It handles up to 1200°C continuously. Short-term use allows higher temps. Sudden temperature changes won’t crack it. This makes it better than regular glass. It suits repeated heating-cooling cycles.

What applications is it used for? Common uses include metal casting, glasswork, or chemical analysis. Labs use it for sample preparation. Jewelers melt precious metals in it. Semiconductor makers grow crystals with it. It works where purity matters. No contamination happens.

How do I clean it after use? Let it cool first. Use warm water and mild detergent. Avoid abrasive scrubbers. Stubborn residue needs diluted acid. Rinse thoroughly. Dry it before reuse. Never expose hot crucibles to cold liquids. Thermal shock risks cracks.

How long does it last? Lifespan depends on usage. Proper care extends it. Avoid mechanical impacts. Store it separately. Check for cracks or cloudiness. Replace if damaged. High-purity fused silica resists wear. Regular inspections ensure safety.

(Fused Silica Quartz Crucible Casting Dish)

REQUEST A QUOTE

RELATED PRODUCTS

Powder Grinding Mill Equipment, Quartz Limestone Kaolin Coal Gypsum Calcite YGM Raymond Grinding Mill

2024 Custom Countertop Quartz Ceramic Tile Sample Desk Rack Display Stand

Factory Custom Heat Resistant Alumina Ceramic Crucible Large Silica Opaque Quartz Crucible

Factory Direct Supply China Quartzite Stone Porcelain Slab Luxury Pandora Brazil Countertop Sintered Stone

Outdoor R7s Ceramic 230v 500w clear Quartz Tube Halogen Infrared Heating Lamp Bulb for Food Warming Dog