Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

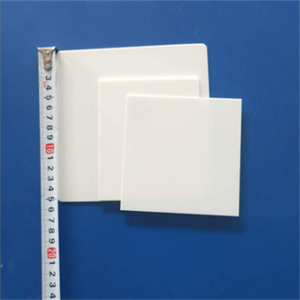

(High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications)

Specifications of High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications

High-temperature immune quartz glass plates are developed for vacuum cleaner heating system applications. These plates handle severe warmth and harsh conditions. The product is fused quartz glass. It offers high pureness and superb thermal security. The optimum constant operating temperature level gets to 1200 ° C. Short-term exposure can withstand as much as 1450 ° C. This makes home plates perfect for procedures like brazing, annealing, and sintering.

Thermal shock resistance is a vital attribute. Home plates endure rapid temperature level changes without splitting. They cool down from 1000 ° C to area temperature in air without damage. Reduced thermal growth makes sure dimensional stability under warm. This prevents bending or distortion during heater cycles.

The glass has high chemical pureness. It includes over 99.99% SiO2. This reduces contamination in vacuum settings. The product resists responses with the majority of acids, gases, and steels. It preserves performance in destructive environments.

Surface top quality is crucial. The plates are polished to a great surface. This ensures smooth call with heater components. Flatness tolerances are firmly regulated. Variances are kept under 0.1 mm per 100mm size. This guarantees correct sealing and warmth distribution.

Standard thickness varies from 5mm to 50mm. Personalized sizes are readily available. Common dimensions include 300x300mm, 400x400mm, and 500x500mm. Bigger plates can be produced for industrial-scale heaters.

Optical transmission residential or commercial properties are significant. The glass allows noticeable and near-infrared light to pass through. This sustains applications requiring thermal tracking or laser heating.

Mechanical stamina suffices for vacuum cleaner use. Home plates stand up to stress distinctions up to 1×10 ^ -6 mbar. They stand up to creep contortion under extended warmth exposure.

Cleaning up and upkeep are simple. The material does not soak up moisture or chemicals. An easy wipe with ethanol or deionized water recovers surface tidiness.

Compatibility with vacuum cleaner systems is ensured. The glass outgasses minimally under heats. This protects furnace vacuum levels.

Applications expand past vacuum furnaces. The plates offer in semiconductor handling, optical tools, and aerospace components. Durability makes certain lengthy service life. Replacement regularity is decreased compared to common glass variations.

(High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications)

Applications of High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications

High-temperature immune quartz glass plates are important parts in vacuum cleaner heater applications. These plates manage extreme warmth and harsh problems efficiently. Their distinct buildings make them suitable for markets calling for exact thermal processing. Quartz glass layers keep structural honesty at temperatures as much as 1200 ° C. They resist thermal shock, making certain sturdiness throughout rapid heating or cooling down cycles. This dependability is vital in vacuum cleaner environments where worldly failing risks contamination or downtime.

The primary use of these plates is as checking out home windows or thermal barriers in vacuum cleaner furnaces. Clear quartz glass permits drivers to keep an eye on procedures without breaking the vacuum cleaner. This exposure is essential in applications like semiconductor manufacturing or metal heat therapy. The material’s high pureness protects against chain reactions with sensitive substances inside the furnace. It makes sure no undesirable bits hinder procedures such as thin-film deposition or crystal development.

Quartz glass plates likewise function as support frameworks for workpieces. Their low thermal expansion coefficient decreases warping under warm. This stability warranties regular positioning of products throughout high-temperature treatments. Industries like aerospace usage these plates for processing advanced alloys. The glass stands up to extended exposure to hostile gases, typical in vacuum brazing or sintering.

One more advantage is optical quality under severe conditions. Unlike other products, quartz glass stays clear even after duplicated home heating. This function sustains applications needing specific light transmission, like laser handling or optical finish. Home plates’ smooth surface stands up to sticking, simplifying maintenance and minimizing contamination risks.

Personalized shapes and thicknesses permit combination into varied furnace styles. Producers commonly coat quartz layers with anti-reflective or conductive layers for specialized requirements. These alterations boost performance without jeopardizing heat resistance.

Quartz glass surpasses options like ceramics or steels in vacuum settings. It incorporates thermal endurance with chemical inertness, ensuring lasting dependability. Individuals benefit from decreased replacement prices and improved procedure consistency. The product’s resistance to devitrification keeps its residential or commercial properties gradually, even in continual operation.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications

What is high temperature resistant quartz glass plate?

High temperature resistant quartz glass plate is a specialized material used in vacuum furnaces. It handles extreme heat without cracking or warping. The main component is silicon dioxide. It has high purity and low thermal expansion. This makes it ideal for environments needing stability under intense temperatures.

How much heat can this quartz glass plate withstand?

The plate can handle temperatures between 1200°C and 1500°C. Exact limits depend on thickness and manufacturing quality. Short-term exposure to higher temperatures is possible. Prolonged use near the upper limit may reduce lifespan. Always check the product specifications for precise ratings.

Why choose quartz glass over other materials for vacuum furnaces?

Quartz glass outperforms metals and ceramics in thermal shock resistance. It does not release harmful gases under vacuum conditions. Its transparency allows visual monitoring of processes. Metals corrode at high temperatures. Ceramics may crack under rapid temperature changes. Quartz glass avoids these issues.

How to clean and maintain the quartz glass plate?

Clean the plate regularly with isopropyl alcohol or distilled water. Avoid abrasive materials that scratch the surface. Check for cracks or discoloration before use. Store in a dry environment to prevent moisture absorption. Handle with gloves to avoid oil contamination. Minor surface flaws can be polished professionally.

Can the plate be customized for specific furnace designs?

Yes. Manufacturers offer custom sizes, shapes, and thicknesses. Provide exact dimensions and temperature requirements. Holes or grooves for mounting can be added. Customization ensures compatibility with unique furnace setups. Lead times vary based on complexity. Confirm details with the supplier before ordering.

(High Temperature Resistant Quartz Glass Plate for Vacuum Furnace Applications)

REQUEST A QUOTE

RELATED PRODUCTS

Whole Ceramic Tile Sintered Stone Display Rack Mosaic Marble Quartz Display Drawer Cabinet Tabletop Display Stand for Tiles

New Crack Series Artificial Calacatta Quartz Stone Slabs Whole Engineered Vanity Tops/Countertops/Table Tops High Quality

Ceramic Liner Ball Mill for Quartz (CE Certification)

Portable Manual Granite Marble Quartz Stone Ceramic Porcelain Tile Edge 45 Degree Chamfer Cutting Machine Countertops Machine

Gas Burner HD220 Industrial Cast Iron Infrared Ceramic Provided 220V SGS Infrared Heaters China Quartz Electric Infrared Heater