Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

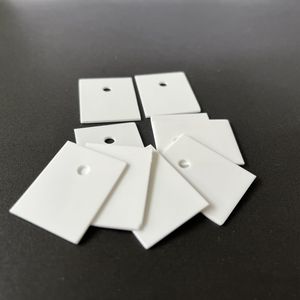

Description

Introduction to Quartz Ceramic Products

Quartz ceramic, also known as fused quartz ceramic or pure silicon ceramic, is an advanced ceramic material made of pure silicon dioxide (SiO₂). It is made by melting high-purity quartz sand at high temperature and then cooling and solidifying it. It has unique physical and chemical properties, making it an ideal choice for many high-tech applications. Quartz ceramic products are widely used in semiconductor manufacturing, optics, electronics, chemical industry and high-temperature industries.

Characteristics and advantages of quartz ceramics

Extremely high thermal stability: Quartz ceramics can remain stable under extreme temperature conditions. They are not only resistant to high temperatures, but also show excellent thermal shock resistance in rapid temperature changes.

Low thermal expansion coefficient: Due to its low thermal expansion coefficient, quartz ceramics have good dimensional stability when the temperature changes and are not easy to deform or crack.

Excellent electrical insulation: Provides excellent electrical insulation performance and is suitable for applications requiring high voltage isolation.

High transparency: It has good light transmittance in a wide band from ultraviolet to infrared, and is particularly suitable for applications such as optical windows and lenses.

Chemical stability: Excellent resistance to most acids, alkalis and other corrosive substances, and almost unaffected by other chemicals except hydrofluoric acid and phosphoric acid.

Mechanical strength: Although quartz ceramic is not as hard as some other types of ceramics, it still has enough mechanical strength to meet the needs of many application scenarios.

High UV transmittance: It has high transmittance in the ultraviolet region, which makes it very useful in UV curing equipment and UV spectrometers.

(Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools)

Specifications of Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools

Quartz ceramic poles act as necessary devices for stirring liquified metals in jewelry production. These rods stand up to extreme temperature levels. The maximum operating temperature reaches 1800 ° C. This ensures integrity during smelting processes. The material structure consists of high-purity quartz ceramic. It stands up to thermal shock efficiently. Abrupt temperature level modifications do not trigger fractures. The rods continue to be secure in harsh settings. Chemical reactions with molten metals are very little. This avoids contamination of priceless products like gold or silver.

The rods include a smooth, non-porous surface. Residue from liquified steels does not stick easily. Cleaning calls for minimal effort. A fast wipe with a fabric often is sufficient. The rods are available in numerous sizes. Usual sizes vary from 6mm to 12mm. Lengths vary between 20cm and 40cm. Customized measurements are offered for particular needs. The straight layout makes sure even distribution of warm. This allows exact control throughout stirring.

Durability stands apart as an essential benefit. Quartz ceramic resists wear from repeated usage. The poles maintain structural integrity gradually. They do not flex or warp under high warmth. This minimizes replacement frequency. Individuals conserve expenses in the long term.

Security functions are prioritized. The rods do not have sharp edges. Handling remains safe during extreme operations. Shielding residential or commercial properties shield customers from straight heat transfer. Heat-resistant handwear covers are still advised for extra security.

Compatibility covers various smelting arrangements. The poles deal with electrical heaters, torches, and crucibles. They suit small fashion jewelry workshops and bigger production devices. Applications extend past rare-earth elements. Glassblowing and lab processes also take advantage of these devices.

Upkeep entails easy actions. Shop the rods in a completely dry area after cooling. Prevent abrupt effects to avoid cracking. Inspect for surface area fractures before each use. Immediate substitute is suggested if damage appears.

Efficiency uniformity makes these rods a functional option. They guarantee uniform blending of molten metals. Bubbles and contaminations distribute efficiently. Last precious jewelry pieces achieve better. Defects like air pockets or uneven appearances are lessened.

The style focuses on user convenience. Light-weight building and construction lowers hand fatigue. A firm hold is feasible also throughout prolonged use. The neutral shade of quartz ceramic enables simple presence of molten metal circulation. Adjustments throughout mixing come to be extra accurate.

(Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools)

Applications of Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools

Quartz ceramic poles serve as essential tools in metal smelting and fashion jewelry making. These poles handle heats without damage. Workers use them to mix molten steels. The process requires materials that endure severe heat. Quartz ceramic poles fit this duty. They stand up to thermal shock. Sudden temperature adjustments do not break them. This makes the rods trusted during repeated home heating and cooling down cycles.

The chemical stability of quartz ceramic pole matters. They do not respond with a lot of metals or alloys. This maintains the liquified product pure. Contaminations can wreck jewelry or steel products. Conventional steel stirring devices sometimes contaminate the mix. Quartz ceramic avoids this issue. Jewelers benefit from clean outcomes. Smelters attain regular steel quality.

Longevity sets these poles apart. They last longer than steel or graphite devices. Steel can melt or warp under high warm. Graphite wears down faster. Quartz ceramic preserves form and toughness. This lowers replacement expenses. Customers conserve money and time over extended periods.

Precision matters in precious jewelry making. Quartz ceramic poles have smooth surface areas. They do not scrape mold and mildews or fragile metal pieces. Fine details remain intact throughout mixing. Smelting applications demand robust performance. The rods manage hostile stirring without damaging. This suits both small jewelry job and huge commercial smelting.

Quartz ceramic rods operate in numerous heaters. Electric, gas, or induction heater all use. The rods execute well in oxygen-rich or inert environments. Individuals change mixing methods without tool restrictions. This flexibility sustains varied metalworking projects.

Managing molten metals requires safety. Quartz ceramic rods stay awesome at the end held by customers. Warmth focuses on the functioning idea. Burns or accidents lower. Workers manage the procedure much better. This boosts overall workshop safety and security.

These poles fit gold, silver, platinum, and other steels. Artisans produce detailed designs without product interference. Industrial smelters produce bulk metal with consistent results. The very same device offers different demands. High-temperature stability and chemical resistance make quartz ceramic rods a functional selection.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools

Quartz ceramic rods are tools for stirring molten metals in jewelry making. They mix materials evenly, remove air bubbles, and help metals cool correctly. These rods work with gold, silver, and similar metals. Their heat resistance makes them dependable for repeated use.

People choose quartz ceramic rods because they withstand high heat without cracking. They do not react with molten metals, keeping the material pure. The smooth surface stops metal from sticking, reducing waste. They last longer than metal or wooden rods, saving costs over time.

These rods handle temperatures up to 1500°C. This suits most jewelry smelting needs. Sudden temperature changes can damage them. Let rods cool slowly after heating to avoid cracks.

Clean rods after each use with a soft brush or cloth. Soak them in warm soapy water for tough residue. Avoid harsh cleaners or scrubbing. Store rods in a dry place. Check for cracks or chips before using them again.

Always use heat-resistant gloves and tongs when handling hot rods. Keep water away from heated rods to prevent shattering. Work in a well-ventilated area to avoid fumes. Let rods cool fully before touching them directly. Replace rods if they show cracks or wear.

(Quartz Ceramic Rods Stirring Rod for Smelting Metal Jewelry Making Tools)

REQUEST A QUOTE

RELATED PRODUCTS

Italy System Bridge Saw Machine for CNC Granite Stone Marble Quartz Ceramic Tile Cutting Machine

High Quality Low Customized Corrosion-Resistant Quartz High Temperature Resistant Ceramic HOP

4 Inch 3-Step Dry Diamond Buffing Polishing Pad for Ceramic/Tile/Marble/Granite/Quartz Stone for Marble & Granite Surfaces

High Quality Rotating Stone Sample Ceramic Quartz Granite Artificial Stone Large Plate Ceramic Tile Display Rack

Good Quality Durable Quartz Coal Grinding Ball Mill , Cement Ceramic Industrial Dry Ball Mill Grinding Machine