Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

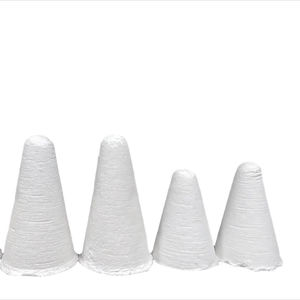

Overview of High Alumina Dense Castable Refractory Product

Discover our robust selection of refractory materials and monolithic solutions, engineered to provide durable linings and structural integrity for high-temperature industrial processes.

Feature of High Alumina Dense Castable Refractory Product

- Abrasion & Corrosion Resistance: Long-lasting performance in aggressive environments.

- High Mechanical Strength: Maintain structural stability under heavy loads and stress.

- Custom Formulations: Tailored castables, cements, and bricks for specific applications.

- Versatile Applications: Ideal for furnaces, kilns, incinerators, and reactors.

Specifications of High Alumina Dense Castable Refractory Product

This castable refractory product handles high heat well. It uses high-purity alumina materials. The alumina content is very high. This makes it strong against heat and wear. It works for very hot applications. People install it by pouring or pumping. Then it sets hard. It bonds tightly after drying and firing.

Its density is high. This means less holes inside. Fewer holes help resist chemical attacks better. It also improves strength. The cold crushing strength is good. This means it bears heavy loads without breaking. It handles sudden temperature changes alright. It resists heat damage over time.

You can shape it easily before it sets. It fits complex shapes well. This helps line furnaces or kilns perfectly. It sticks well to other refractories or metal shells. It works for backup layers and hot face linings both. It’s common in steel plants and petrochemical heaters.

Its performance depends on proper installation. Follow the maker’s mixing instructions exactly. Use the right amount of water. Cure it slowly at first. Heat it up gradually during drying. This prevents cracks. Always fire it to the recommended temperature. This makes it fully strong. It lasts longer that way.

This dense castable handles tough conditions. It withstands hot gases and slag. It works in areas needing strong, dense linings. It’s reliable for demanding industrial heat processes.

Applications of High Alumina Dense Castable Refractory Product

High alumina dense castable refractory is a special kind of fire-resistant material. People mix it with water, pour it into shapes, and let it harden. It handles extremely high temperatures very well. This makes it useful in many tough industrial places.

Boilers and furnaces often use this material. It lines the hot areas inside. The dense castable protects the outer steel shell from melting or warping. It withstands the constant heat from burning fuel. This helps the equipment last longer and run safely.

Steel plants rely heavily on this castable. It shapes troughs for moving molten metal. It forms protective linings around ladles holding liquid steel. It builds the inner walls of mixers blending hot metals. The material resists the intense heat and chemical wear from molten steel.

Foundries also use this product. It lines induction furnaces melting metals like iron. It protects areas where metal is poured. The castable handles the heat and prevents damage to furnace parts. This reduces downtime for repairs.

Power plants need it too. It lines areas inside waste incinerators burning trash. It protects parts in cement kilns making clinker. It withstands the high heat and harsh chemicals in these environments. This keeps the plants running smoothly.

Chemical plants use it for reactors and heaters. The dense castable resists high temperatures and some corrosive chemicals. It provides a stable lining inside process vessels. This is crucial for safe chemical production.

Installing it is straightforward. Workers mix the dry powder with clean water. They pour or pump the wet mixture into the needed space. They vibrate it gently to remove air bubbles. After it hardens, it forms a strong, solid lining. Proper curing ensures it reaches full strength.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Alumina Dense Castable Refractory Product

People ask about High Alumina Dense Castable Refractory often. Here are five common questions.

What is High Alumina Dense Castable Refractory? It’s a special kind of cement. It’s made from very hard materials. These materials include things like calcined alumina. It handles very high heat well. You mix it with water. Then you pour it or pump it into place. It sets hard.

Why pick this castable? It lasts a long time under heat. It resists damage from chemicals. It also handles sudden temperature changes okay. It forms a strong, dense lining. This lining protects furnaces and kilns. It keeps the heat inside well.

How do you install it? First, clean the surface well. Mix the dry powder with clean water. Follow the instructions for how much water. Mix it until smooth. Pour it or pump it into the mold or form. Use tools to shape it properly. You need to work quickly before it sets.

How hot can it get? This castable handles very high temperatures. It usually works well above 1500°C. The exact top temperature depends on the specific grade. Always check the manufacturer’s data sheet. Know the limits for your specific application.

How long does it take to cure and dry? It sets within a day usually. But it needs more time to dry fully. This drying removes all the moisture. Proper drying is crucial. It prevents cracks or explosions later. Follow the heating schedule exactly. Start slowly. Increase the temperature gradually.

REQUEST A QUOTE

RELATED PRODUCTS

Shandong Refractory Silicon Carbide Ceramic Sic Beam / Kiln Furniture Sic Heating Element For Casting Industry

High Alumina Refractory Brick Industrial Fire Bricks with Welding and Cutting Services Competitive

High Heat Resistance Refractory Mullite Ceramic Tube for Electrical Resistor Capacitor Insulator

Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

Refractory Porcelain Ceramic Crucible 20ml 30ml 50ml 150mm For Melting