Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

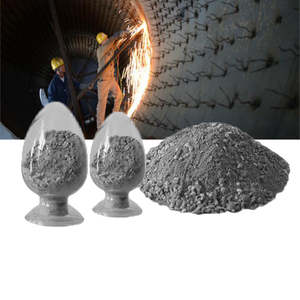

Overview of High Density 325Mesh 600Mesh Bulk Industrial Ceramic Glaze Refractory Clay Raw for Papermaking Coating

Discover our robust selection of refractory materials and monolithic solutions, engineered to provide durable linings and structural integrity for high-temperature industrial processes.

Feature of High Density 325Mesh 600Mesh Bulk Industrial Ceramic Glaze Refractory Clay Raw for Papermaking Coating

- Abrasion & Corrosion Resistance: Long-lasting performance in aggressive environments.

- High Mechanical Strength: Maintain structural stability under heavy loads and stress.

- Custom Formulations: Tailored castables, cements, and bricks for specific applications.

- Versatile Applications: Ideal for furnaces, kilns, incinerators, and reactors.

Specifications of High Density 325Mesh 600Mesh Bulk Industrial Ceramic Glaze Refractory Clay Raw for Papermaking Coating

This bulk industrial ceramic glaze refractory clay is high density material. It comes in two common mesh sizes: 325 mesh and 600 mesh. These numbers tell you about the fineness. The particles are very small. The 600 mesh powder is finer than the 325 mesh powder. Both sizes are good for many industrial jobs.

The clay is a refractory material. This means it can handle very high heat without changing. It keeps its shape and strength. This is important in kilns and furnaces. The high density gives it this heat resistance. The material packs tightly together. This makes it strong and durable under stress.

This clay is a key ingredient in ceramic glazes. It helps the glaze stick to the pottery. It affects the final finish and color. The fine mesh sizes mix easily into glaze formulas. They create smooth, even coatings. The high density provides stability during firing. It prevents defects like cracking or bubbling.

It is also used in papermaking coatings. Adding this clay to the coating mix improves the paper surface. It makes the paper smoother. It improves how ink sits on the paper. It also makes the paper brighter and more opaque. The fine particles fill tiny spaces well. The high density helps in creating a strong coating layer. This clay is reliable and consistent. Paper mills get good results batch after batch.

The product is sold in bulk quantities. It is cost-effective for large operations. The raw material is processed carefully. It is mined and refined to meet strict standards. Impurities are removed. This ensures high purity and performance. Users get a clean, reliable product. It performs well in demanding applications. The material is ready for mixing into glazes or paper coatings.

Applications of High Density 325Mesh 600Mesh Bulk Industrial Ceramic Glaze Refractory Clay Raw for Papermaking Coating

This industrial ceramic glaze clay comes in two mesh sizes: 325 and 600. It’s a bulk refractory clay raw material. It works well for papermaking coatings. Paper mills use coatings to make paper look better and print better. This clay helps achieve that. Fine clay particles fill the spaces between paper fibers. This creates a smoother surface. A smooth surface is good for printing. It lets ink sit evenly on the paper. Sharp images and clear text result. This clay also improves the paper’s whiteness. It boosts brightness too. It increases opacity. Opacity means you can’t see through the paper. These properties are important for high-quality printing. The clay particles are very fine. They bind well with other coating ingredients. These ingredients include binders and additives. The mixture forms a uniform slurry. Mills apply this slurry to the paper surface. They use special coating machines. The clay’s refractory nature is key. It handles the drying process well. High heat is used to dry coated paper. The clay doesn’t break down. It keeps the coating stable. It ensures consistent performance. Paper mills value reliability. This clay provides that. Using 325Mesh or 600Mesh clay offers choices. Finer mesh gives an even smoother finish. It depends on the paper grade needed. Both sizes enhance coating efficiency. They help reduce coating weight sometimes. This saves material costs. It maintains quality. The clay is easy to disperse in water. This simplifies the coating preparation. It mixes well without clumping. Production runs stay smooth. Fewer problems happen. The clay is a practical choice. It delivers the required coating properties. Paper producers get good results. They make better coated paper products. Customers appreciate the final paper quality. It meets demanding print job requirements.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Density 325Mesh 600Mesh Bulk Industrial Ceramic Glaze Refractory Clay Raw for Papermaking Coating

What is this ceramic glaze refractory clay for papermaking coating?

This material is a specially prepared clay powder. It comes in fine mesh sizes like 325 and 600. Manufacturers use it to coat paper surfaces. The coating improves paper quality. It makes paper smoother, brighter, and better for printing.

Why are there different mesh sizes like 325 and 600?

Mesh size indicates particle fineness. A 600 mesh is finer than a 325 mesh. Finer particles create a smoother coating layer. Smoother coating improves paper finish and printability. The choice depends on the desired paper quality. Some grades need finer particles.

How is this clay used in paper coating?

Papermakers mix the clay powder with water and binders. This forms a coating slurry. The slurry is applied to paper surfaces. It can be applied during the papermaking process. After application, the coated paper is dried. The dried coating becomes part of the paper surface.

What benefits does this clay offer in paper coating?

This clay provides excellent brightness and opacity. It helps create a smooth, uniform surface. A smooth surface accepts ink well during printing. The clay also improves paper gloss. Good gloss makes printed images look sharp and vibrant.

How is the clay supplied?

We supply this refractory clay in bulk quantities. It is packed securely in large bags. These bags are designed for industrial handling. Bulk supply is cost-effective for large paper mills. It reduces packaging waste too.

REQUEST A QUOTE

RELATED PRODUCTS

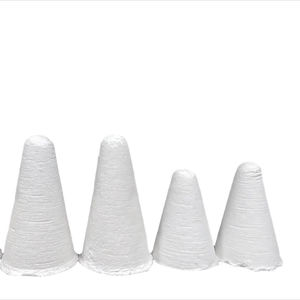

High Temperature Alumina Refractory Brick Curved Fire Bricks Tapered Skewed Arc Fire Clay Brick for Oven Kiln

Factory Direct Whole Industrial Grade White Pyrophyllite Stone Powder Ceramic Refractory Material SIO2

Refractory Industrial Electrical Insulation 95% Al2O3 Alumina Ceramic Tubes Aluminum Oxide Insulator

Silicon Carbide Refractory Panel Silicon Carbide Refractory Brick Panel As Kiln Shelves

High Aluminum Refractory Castable DIY Levels Ceramic Raw Materials Alumina Cement-Direct