Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

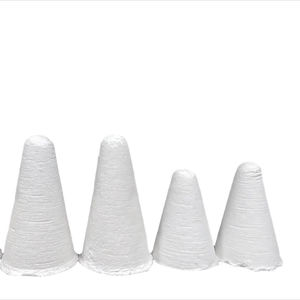

Overview of OEM Refractory Industrial High Temperature Resistance 99% Al2O3 Rod Cylinder Alumina Ceramic Tube

Discover our robust selection of refractory materials and monolithic solutions, engineered to provide durable linings and structural integrity for high-temperature industrial processes.

Feature of OEM Refractory Industrial High Temperature Resistance 99% Al2O3 Rod Cylinder Alumina Ceramic Tube

- Abrasion & Corrosion Resistance: Long-lasting performance in aggressive environments.

- High Mechanical Strength: Maintain structural stability under heavy loads and stress.

- Custom Formulations: Tailored castables, cements, and bricks for specific applications.

- Versatile Applications: Ideal for furnaces, kilns, incinerators, and reactors.

Specifications of OEM Refractory Industrial High Temperature Resistance 99% Al2O3 Rod Cylinder Alumina Ceramic Tube

This product is 99% alumina ceramic. It’s for industrial heat use. The material handles extreme warm well. Maximum continual temperature level is 1650 ° C. Short term optimal temperature level gets to 1700 ° C. This makes it ideal for furnaces, kilns, and reactors. The tubes, rods, and cylinders resist thermal shock properly.

Alumina ceramic deals high mechanical stamina. It stands up to hefty loads without breaking. The product is really hard. It withstands wear and abrasion with time. Chemical stability is exceptional. Acids and alkalis cause minimal damages. This durability is very important for severe industrial settings.

Electric insulation residential properties are great. The product functions well as electrical insulation in hot environments. Reduced electrical conductivity prevents existing leakage. This is vital for burner and sensor security. The surface coating is smooth. This lessens friction and contamination.

We create these components in numerous dimensions. Criterion sizes range from 5mm to 150mm. Typical sizes rise to 1000mm. Customized measurements are possible. Wall thickness depends upon the application. We manufacture poles, strong cyndrical tubes, and hollow tubes. All forms keep the core product buildings.

The alumina ceramic is dense. Density is typically 3.7 g/cm THREE. This contributes to its durability. Reduced porosity guarantees very little gas leaks in the structure. The shade is white. The surface is fine-grained. Dimensions are specific. Tolerances meet commercial demands. This product is reliable for demanding technological uses.

Applications of OEM Refractory Industrial High Temperature Resistance 99% Al2O3 Rod Cylinder Alumina Ceramic Tube

These alumina ceramic tubes deal with severe warmth. They are made from 99% pure light weight aluminum oxide. This pureness provides superb homes. They resist temperature levels far beyond what a lot of materials can take. They stay strong under thermal anxiety. They resist chemical attack extremely well. They are good electrical insulators. They are additionally really difficult and put on resistant.

Several sectors require such dependable materials. Steel plants and shops use these tubes continuously. They protect thermocouples inside molten steel. They line view openings for heater surveillance. They create crucibles for melting unique alloys. Televisions don’t thaw or infect the metal.

Chemical plants rely upon these ceramics too. They manage destructive gases and liquids at high warmth. They act as activator linings. They are utilized for heater nozzles. They guide hostile chemicals securely. The product does not respond easily.

Warm therapy furnaces benefit significantly. These tubes create vital furnace furnishings. They are made use of as setters, supports, and rollers. They bring components through hot zones. They hold up against repeated home heating and cooling down cycles. They maintain dimensional stability. This guarantees constant part quality.

Semiconductor production requires severe purity. These high-purity alumina tubes are important. They carry wafers throughout high-temperature procedures. They act as insulators in deposition devices. They develop components for diffusion furnaces. They stop contamination of sensitive electronics.

Various other applications exist. They shield burner properly. They form components for research laboratory test devices. They are used in high-temperature sensors. They develop resilient guides and bushings. Any kind of place requiring long life under intense warm and rough conditions is a potential usage. These tubes offer a trustworthy service. They minimize downtime. They lower substitute expenses. They improve process integrity. Their performance is shown popular commercial setups.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of OEM Refractory Industrial High Temperature Resistance 99% Al2O3 Rod Cylinder Alumina Ceramic Tube

What’s the highest temperature these alumina tubes handle?

These tubes work reliably up to 1800°C (3272°F). They manage extreme heat found in furnaces, kilns, and reactors. They resist thermal shock well. Sudden temperature changes cause less cracking.

Why is 99% Al2O3 important?

High alumina content means better performance. 99% Al2O3 gives maximum temperature resistance. It improves chemical stability. The material resists acids and alkalis better. It delivers superior mechanical strength compared to lower grades.

Where are these ceramic tubes typically used?

They serve many high-heat industrial jobs. Common uses include furnace linings, thermocouple protection sleeves, and heating element supports. They work in metal processing, glass manufacturing, and chemical plants. They insulate or protect parts in harsh environments.

How long do these alumina tubes last?

They last much longer than metal alternatives under extreme heat. Their high purity alumina structure resists wear and corrosion. They withstand erosion from hot gases and particles. This reduces frequent replacements and downtime. Maintenance costs decrease.

Can you make custom sizes and shapes?

Yes. We produce tubes to exact OEM specifications. Tell us the outer diameter, inner diameter, length, and any special features needed. We manufacture custom alumina rods and cylinders. We meet specific dimensional and tolerance requirements.

REQUEST A QUOTE

RELATED PRODUCTS

High Aluminum Refractory Castable DIY Levels Ceramic Raw Materials Alumina Cement-Direct

Refractory Ceramic Fiber Cotton Bulks for Thermal Insulation Ceramic Fiber Wool

High Heat Resistance Refractory Cordierite Mullite Ceramic Part For

Refractory Ceramic Fiber Sleeve Insulation Ceramic Pipes & Tubes

Refractory Insulation 1430 Ceramic Fiber Module Aluminum Silicate Cotton Blocks For Kiln