Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

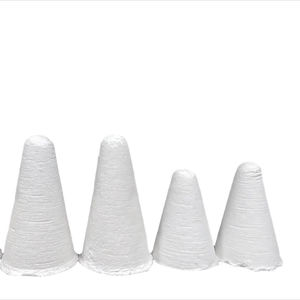

Overview of Refractory Mullite / Cordierite Ceramic Component For Heating

Discover our robust selection of refractory materials and monolithic solutions, engineered to provide durable linings and structural integrity for high-temperature industrial processes.

Feature of Refractory Mullite / Cordierite Ceramic Component For Heating

- Abrasion & Corrosion Resistance: Long-lasting performance in aggressive environments.

- High Mechanical Strength: Maintain structural stability under heavy loads and stress.

- Custom Formulations: Tailored castables, cements, and bricks for specific applications.

- Versatile Applications: Ideal for furnaces, kilns, incinerators, and reactors.

Specifications of Refractory Mullite / Cordierite Ceramic Component For Heating

This ceramic part handles intense heat. It’s made primarily from mullite and cordierite. These materials are minerals discovered in nature. They provide the ceramic its unique warmth resistance. The part is created for home heating tasks. It functions well inside furnaces and kilns.

The product resists extremely heats. It manages continuous consume to 1550 ° C. Short ruptureds of warm up to 1700 ° C are alright. This is its optimum functioning temperature level. It doesn’t thaw or compromise conveniently at these warms. The ceramic also takes care of abrupt temperature adjustments well. It will not fracture conveniently when heating up quickly or cooling off promptly. This home is called thermal shock resistance.

Warm doesn’t travel through this ceramic quick. That means it’s a great insulator. It keeps warm where you desire it. The product stays strong under stress at heats. Its strength stands up also when it’s really hot. The ceramic is likewise difficult. It resists getting worn down or scraped. It does not react much with various other chemicals. This makes it steady in challenging atmospheres. Acids and bases normally do not damage it much.

The ceramic doesn’t carry out electricity well. It’s an electric insulator. This is essential for some heating tasks. You can get this part in various shapes. Tubes, plates, and custom types are common. Criterion dimensions are available. Special dimensions can be made as well. The surface finish is normally smooth. This assists with performance and cleaning.

This ceramic operate in lots of high-heat situations. It benefits heating system linings. It’s used in kiln furnishings. It supports items being discharged. It works as insulation boards. It works as heating element supports. It functions as thermocouple protection tubes. Its primary job is managing severe warm reliably. It lasts a long time under tough problems.

Applications of Refractory Mullite / Cordierite Ceramic Component For Heating

Refractory mullite and cordierite ceramics manage severe warm well. They fix large issues in high-temperature home heating jobs. These products last much longer than lots of steels or various other porcelains under hard conditions. That saves cash and downtime.

Mullite ceramic is terrific for really heats. It remains solid and withstands chemical assault near 1800 ° C. Individuals utilize it for kiln furniture. This implies shelves and messages holding things inside commercial kilns. Mullite racks support hefty loads during shooting. Heating system cellular linings additionally utilize mullite. It protects warmth effectively inside metal melting or heat treatment heating systems. Thermocouple protection tubes are an additional essential use. Mullite guards the fragile temperature level sensing units in severe heating system ambiences.

Cordierite ceramic is different. Its large advantage is resisting thermal shock. This indicates it handles quickly temperature modifications without splitting. Cordierite doesn’t increase much when heated. This is essential for parts seeing fast warmth cycles. Kiln furnishings typically utilizes cordierite also. It functions especially well for rapid firing cycles like in floor tile production. Warm exchanger parts benefit from cordierite. Recuperating warm from hot exhaust gases requires products making it through continuous cooling and heating. Burner nozzles face straight flame get in touch with. Cordierite handles the extreme regional warm and thermal tension there. Semiconductor processing equipment needs ultra-clean, steady materials. Cordierite parts offer dependably in these essential home heating areas.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Mullite / Cordierite Ceramic Component For Heating

Here are key questions people ask about our refractory mullite and cordierite ceramic heating parts:

What temperature can these parts handle? Mullite parts withstand very high heat, easily over 1700°C. Cordierite handles lower temperatures, usually up to about 1200°C. Choose based on your furnace’s maximum operating temperature.

Do these ceramics resist thermal shock? Yes, both materials handle temperature changes well. Cordierite usually performs better under very rapid heating or cooling cycles. Mullite offers good shock resistance too, especially at its higher temperature range.

How long do these parts last? Lifespan depends heavily on use. Constant extreme temperatures, rapid cycling, and physical wear affect durability. Proper installation and avoiding mechanical stress help maximize part life. Expect good long-term service under normal conditions.

How do I clean these components? Avoid harsh chemical cleaners or abrasive scrubbing. Gentle brushing removes loose debris. Compressed air works well for dust. Check for embedded material needing careful removal. Keeping parts clean maintains efficiency.

Mullite or cordierite – which is better? It depends on your needs. Mullite is best for extreme, sustained high temperatures. Cordierite excels where rapid temperature changes happen frequently, even at slightly lower peak temperatures. Consider your specific heating process.

REQUEST A QUOTE

RELATED PRODUCTS

Refractory Fire Brick High Performance Dense 1800 Aluminum Firebrick 230 X 114 X 65 mm Refractory High Alumina Brick s

High Aluminum Refractory Castable DIY Levels Ceramic Raw Materials Alumina Cement-Direct

1000-1600 C Fire Resistant Refractory Thick 3~200 Mm Ceramic Fiber Board

Refractory Insulation 1430 Ceramic Fiber Module Aluminum Silicate Cotton Blocks For Kiln

Mullite-Cordierite Plate 1250c Refractory Cordierite Mullite Ceramic Plate for Ceramic Kiln