Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

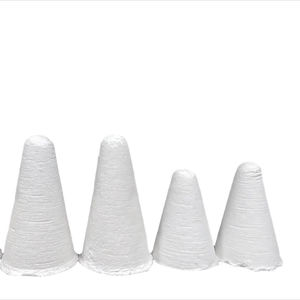

Overview of Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

Discover our robust selection of refractory materials and monolithic solutions, engineered to provide durable linings and structural integrity for high-temperature industrial processes.

Feature of Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

- Abrasion & Corrosion Resistance: Long-lasting performance in aggressive environments.

- High Mechanical Strength: Maintain structural stability under heavy loads and stress.

- Custom Formulations: Tailored castables, cements, and bricks for specific applications.

- Versatile Applications: Ideal for furnaces, kilns, incinerators, and reactors.

Specifications of Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

Reusable aluminum silicate ceramic lauer raw materials work well for making alumina die casting refractory ceramic parts. This material offers dependable performance and handles the casting process effectively. Its composition is mainly aluminum silicate. This gives it strong heat resistance properties. The material is designed for reuse. This saves money over time. You get consistent quality batch after batch.

The particle size distribution is controlled carefully. This ensures good flow when filling molds. It also helps create dense, strong ceramic parts after firing. The moisture content stays low. This prevents cracking or damage during drying and firing stages. It handles very high temperatures easily. This is essential for alumina die casting applications. The material withstands thermal shock well. Sudden temperature changes won’t cause failures.

A key benefit is its cut-process-friendly nature. Machining and cutting this material is straightforward. It produces clean edges and precise shapes without excessive tool wear. This reduces waste significantly. Less material is lost during shaping. Handling the material is simple before and during the die casting process. Its reusability is proven. Multiple cycles maintain its performance integrity. Chemical stability is high. It resists reactions with molten alumina effectively. This ensures the final cast parts remain pure and meet specifications. Expect reliable results for demanding refractory applications.

Applications of Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

Reusable aluminum silicate ceramic lauer raw materials are special. They help make alumina die casting better for tough ceramic parts. These parts handle extreme heat. Die casting uses molds filled with very hot, liquid metal. The molds need strong linings. These linings face intense heat and wear. Our aluminum silicate ceramic raw materials are perfect for this job. They are designed to be reused. This saves money and cuts waste. Factories like that. The material is also cut-process-friendly. Machining it is easier. You can cut and shape it without too much trouble. This saves time and tool costs. Tool wear is less. That means less downtime for changing tools. Production stays smooth. The material handles the high temperatures in alumina die casting very well. It resists thermal shock. Sudden temperature changes won’t easily crack it. This leads to longer-lasting molds and parts. It also resists corrosion from the molten metal. This keeps the cast parts pure and high quality. Using this material improves the overall efficiency of making refractory ceramic parts. It makes the die casting process more reliable. You get consistent results batch after batch. The reusability factor is a big plus. After one use cycle, the material can often be reprocessed and used again. This reduces the need for constant new raw materials. It lowers production costs significantly over time. We see this often in demanding foundry applications. Performance stays strong even under heavy use. The combination of heat resistance, easy machining, and reuse potential makes it a smart choice. It directly tackles the core challenges in alumina die casting for refractory parts.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Reusable Aluminum Silicate Ceramic Lauer Raw Materials Cut-Process-Friendly for Alumina Die Casting for Refractory Ceramic Parts

Reusable Aluminum Silicate Ceramic Lauer Raw Materials: Cut-Process-Friendly for Alumina Die Casting – FAQ

What makes these raw materials special?

These aluminum silicate ceramic lauer raw materials are reusable. They are also designed to be cut-process-friendly. This combination is key for making refractory ceramic parts. It saves money and improves manufacturing efficiency.

Why does reusability matter for alumina die casting?

Alumina die casting involves extreme heat and wear. Refractory parts fail quickly. Reusing these materials lowers replacement costs. It reduces waste. Production downtime decreases significantly. Your overall operating costs go down.

How does the cut-process-friendly design help?

The material handles cutting and shaping easily. Machining complex parts is simpler. Tool wear is reduced. Production speeds increase. You get precise ceramic components faster. Less material is wasted during machining. This saves time and money.

What temperature can these materials handle?

They withstand very high temperatures. This is essential for alumina die casting environments. The materials maintain strength and stability under intense heat. They resist thermal shock well. Your ceramic parts last longer in demanding conditions.

Are these materials good for all alumina die casting parts?

They are specifically designed for alumina die casting refractory components. Their properties match this application perfectly. They resist molten alumina corrosion. They handle thermal cycling stress. Performance is reliable for liners, nozzles, and other critical parts.

REQUEST A QUOTE

RELATED PRODUCTS

Refractory Ceramic Fiber Sleeve Insulation Ceramic Pipes & Tubes

Welding Cutting Bending Services Included Insulating Refractory Ceramic Mold Riser Sleeves With Straight Barrel Casting

High Aluminum Refractory Castable DIY Levels Ceramic Raw Materials Alumina Cement-Direct

Factory Composites Ceramic Sintering Powder Circular Of Used Refractory Kiln Cordierite Mullite Sagger

Refractory Porcelain Ceramic Crucible 20ml 30ml 50ml 150mm For Melting