Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

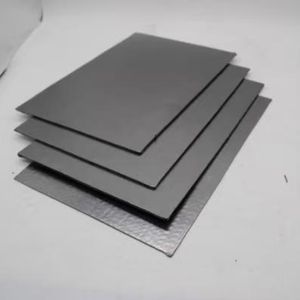

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

(Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing)

Specification of Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing

The Personalized Silicon Carbide Ring (SSIC/SIC Ceramic Sealing) is made for high-performance sealing popular atmospheres. Made from costs silicon carbide ceramic, it offers exceptional longevity. The product combines high solidity, superb thermal conductivity, and resistance to severe temperatures. It operates effectively in problems varying from -50 ° C to 1600 ° C. This makes it suitable for applications where steels or polymers fall short.

The ring is engineered for chemical stability. It resists deterioration from acids, alkalis, and abrasive media. This ensures long-term reliability in aggressive industrial setups. Modification options consist of tailored dimensions, surface area finishes, and tolerance degrees. Details geometries can be produced to match distinct machinery or system needs.

Silicon carbide’s low thermal development minimizes contortion under quick temperature adjustments. This decreases leakage threats in high-pressure systems. The product’s wear resistance prolongs service life, lowering substitute regularity. It is perfect for pumps, shutoffs, and mechanical seals in chemical handling, oil and gas, or power generation sectors.

The manufacturing process makes use of innovative sintering methods. This accomplishes high-density structures with minimal porosity. Surface area grinding ensures precise monotony and smoothness for ideal securing call. Optional layers enhance performance in specialized scenarios.

Secret specs include a thickness of 3.1-3.2 g/cm THREE, Vickers firmness over 2500 HV, and fracture durability of 4.0 MPa · m 1ST/ ². The ring maintains structural stability under mechanical stress and anxiety. Electrical insulation properties stop current leak in electrically active settings.

Custom-made Silicon Carbide Bands work with a lot of liquids and gases. They outperform traditional materials like tungsten carbide or alumina porcelains. Customized orders need comprehensive criteria such as inner/outer sizes, density, and surface area roughness. Lead times vary based upon style complexity.

The item satisfies global requirements for industrial porcelains. Quality checks include dimensional verification, firmness testing, and leak resistance tests. Mass orders obtain affordable prices. Technical support is available for integration difficulties or material selection support.

(Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing)

Applications of Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing

Customized silicon carbide rings (SSIC/SIC ceramic sealing) offer critical duties throughout industries needing high-performance products. These parts master extreme environments as a result of their special residential or commercial properties. Silicon carbide provides extraordinary solidity, thermal stability, resistance to use, and chemical corrosion. These traits make it excellent for applications where metals or polymers stop working.

In aerospace, silicon carbide rings deal with high-temperature jet engine elements. They maintain architectural integrity under extreme warm and mechanical stress and anxiety. Their low thermal expansion lowers leakage threats in gas and hydraulic systems. This integrity enhances security and efficiency in aircraft procedures.

The vehicle sector uses these rings in turbocharger systems and exhaust administration. They stand up to rapid temperature level changes and abrasive problems. This improves engine efficiency and minimizes maintenance demands. Electric car battery production likewise takes advantage of their electric insulation residential or commercial properties.

Chemical handling plants count on silicon carbide seals for pumps, valves, and reactors. They resist assault from acids, antacid, and solvents. This prolongs devices life expectancy and avoids hazardous leakages. Their longevity guarantees constant procedure in hostile chemical settings.

Power production systems, including nuclear and solar power, utilize these rings for sealing and insulation. In atomic power plants, they endure radiation exposure without deteriorating. Solar thermal applications leverage their capacity to withstand concentrated heat fluxes. This sustains efficient power conversion and long-lasting system integrity.

Semiconductor manufacturing needs ultra-pure materials for contamination control. Silicon carbide’s inertness stops reactions with handling gases or plasmas. It makes certain precise wafer handling and chamber securing throughout chip fabrication.

Personalization permits these rings to satisfy exact specs for size, geometry, and surface coating. Engineers adjust them for one-of-a-kind pressure ratings, thermal cycles, or chemical direct exposures. This versatility ensures optimum performance in specialized applications.

Silicon carbide’s mix of mechanical stamina and environmental resistance makes it a preferred choice for advanced securing solutions. Industries prioritize it to improve functional safety, decrease downtime, and lower long-term expenses.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing

Customized silicon carbide rings (SSIC/SIC) are used in many industries. Here are five common questions. What makes silicon carbide rings better than other materials? Silicon carbide has high hardness. It resists wear better than metals or plastics. It handles extreme temperatures. It works in environments up to 1600°C. It also resists corrosion. Acids and alkalis don’t damage it easily. This makes it last longer in tough conditions. Can these rings be made to fit specific machines? Yes. Manufacturers adjust sizes and shapes. They match exact measurements from clients. Custom designs include special grooves or coatings. This ensures the ring fits perfectly. It improves sealing performance. How do silicon carbide rings handle high-pressure situations? The material’s structure is very dense. It doesn’t crack under pressure. It keeps seals tight even with rapid pressure changes. This reliability prevents leaks in pumps or valves. Do these rings need special maintenance? No. Silicon carbide doesn’t degrade quickly. Regular cleaning removes debris. No lubrication is needed. This reduces downtime. It saves costs over time. How do I choose the right type of silicon carbide ring? Consider the operating conditions. Temperature and pressure matter. Chemical exposure matters too. Check if static or rotating parts need sealing. Discuss requirements with the supplier. They recommend the best grade. Custom options solve unique challenges.

(Customized Silicon Carbide Ring SSIC SIC Ceramic Sealing)

REQUEST A QUOTE

RELATED PRODUCTS

Hot ing Cheap F4-F6000 Honeycomb Ceramic Filter Dust Removal Powder Siliconcarbide Black Silicon Carbide Powder for Blasting

1625C U W I Type Silicon Carbide Ceramic Heating Element Rods for Muffle Furnace

High Purity Silicon Carbide Fine Ball Customize Ceramic SiC Ball

Square / Hexagonal / Cylinder / Rectangle / Single-curved / Cut-angle Boron Carbide / Alumina / Silicon Carbide Ceramic Plate

0.4mm-100mm G10 Ceramic Balls Silicon Carbide Ball Sic For Bearings 2mm Sic Balls