Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Carbide Ceramics

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Silicon Carbide Ceramics

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

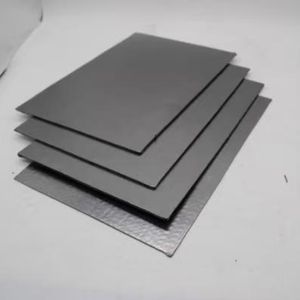

(MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment)

Specification of MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment

The MBR Membrane Layer High Change Silicon Carbide Apartment Sheet Ceramic Membrane is created for advanced water treatment applications. This membrane layer combines silicon carbide’s longevity with a high-flux layout to improve filtering effectiveness. It manages demanding environments properly. The level sheet structure guarantees secure efficiency in wastewater therapy, industrial processes, and reuse systems.

The membrane utilizes silicon carbide as the core material. This product provides exceptional mechanical strength. It withstands corrosion, high temperatures, and abrasive substances. The membrane operates in pH arrays from 0 to 14. It stands up to temperatures as much as 80 ° C. These features make it suitable for extreme commercial wastewater therapy.

The high-flux layout enhances water leaks in the structure. It minimizes energy intake throughout filtration. The consistent pore structure makes certain consistent splitting up of suspended solids, microorganisms, and organic matter. The average pore size is 0.1 microns. This obstructs impurities successfully while permitting clean water to go through.

Installment and maintenance are streamlined. The level sheet components fit into typical MBR systems. They need marginal cleaning cycles. Chemical resistance prolongs the membrane’s lifespan. It prevents regular substitutes. Operators save expenses in time.

Technical specs consist of a filtration location of 25-50 square meters per component. The transmembrane stress arrays from 0.1 to 0.3 MPa. Flow rates differ based upon application needs. The membrane’s thickness is 6-8 mm. It makes certain architectural integrity under high-pressure conditions.

Applications cover metropolitan wastewater therapy, food and drink processing, pharmaceutical production, and chemical manufacturing. It removes pollutants from oily wastewater, hefty metal-laden streams, and high-salinity options. The membrane sustains lasting water reuse objectives.

Key advantages consist of lasting security, low fouling rates, and compatibility with hostile cleaner. The rigid ceramic structure protects against membrane layer contortion. It preserves performance under continual operation. These attributes make it a dependable selection for industries focusing on effectiveness and resilience.

The product meets international requirements for water treatment products. It undertakes rigorous quality testing. Each batch is inspected for problems. Clients get constant, high-performance membranes customized to commercial needs.

(MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment)

Applications of MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment

The MBR membrane layer high-flux silicon carbide flat sheet ceramic membrane layer is a crucial option for contemporary water therapy. This item uses innovative silicon carbide material. It integrates stamina with high filtration performance. The level sheet layout raises surface area. This enables faster handling of huge water volumes. It works well in challenging problems like heats or harsh settings.

This membrane layer is utilized commonly in industrial and metropolitan water therapy. It treats wastewater from factories, getting rid of unsafe materials properly. It handles heavy tons of raw material and little fragments. It is suitable for industries like chemicals, pharmaceuticals, and food processing. These markets require rigorous water top quality requirements. The membrane layer fulfills these by filtering germs, viruses, and put on hold solids.

The ceramic framework provides resilient efficiency. It resists wear and chemical damages. This reduces downtime and maintenance prices. The high change rate suggests much less power is needed to press water via the system. This saves functional expenditures. The membrane’s pore size is specific. It guarantees constant water quality without clogging concerns.

This modern technology supports water reuse tasks. It turns wastewater right into secure water for irrigation or industrial processes. It assists areas encountering water shortages. The system is very easy to clean. Normal backwashing or air scouring maintains it effective. Its modular layout allows adaptable installation in existing arrangements.

The membrane layer works in cardio and anaerobic bioreactors. It improves treatment capability in small spaces. It is a reliable option for updating old plants. The silicon carbide product outshines conventional polymer membranes. It lasts longer under rough conditions. Its thermal stability suits high-temperature applications.

Operators benefit from lower replacement expenses. The membrane’s resilience reduces waste. It straightens with sustainability goals. The product satisfies global standards for water safety and security. It is a practical investment for reliable, environmentally friendly therapy systems.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment

What is the MBR membrane high flux silicon carbide flat sheet ceramic membrane? This membrane is a filtration tool for water treatment. It uses silicon carbide material. The flat sheet design helps remove impurities from water. It works by allowing clean water to pass through tiny pores. Contaminants get trapped on the surface. This process is efficient for treating wastewater.

Why choose this ceramic membrane over traditional options? Traditional membranes clog easily. This silicon carbide membrane resists fouling better. High flux means it processes water faster. It handles harsh chemicals and high temperatures. This reduces downtime for cleaning. Maintenance costs drop over time.

How is the membrane cleaned? Regular cleaning keeps it working well. Backwashing pushes water backward to remove debris. Chemical cleaning uses mild acids or alkalis. Sodium hypochlorite solutions clear organic buildup. Always follow manufacturer guidelines. Proper cleaning extends the membrane’s life.

What is the membrane’s lifespan? It lasts longer than polymer membranes. Typical use gives 5-8 years of service. Actual lifespan depends on water quality. Harsh conditions or poor maintenance shorten it. Checking performance regularly helps spot issues early. Replacing damaged sheets quickly avoids bigger problems.

Is this membrane cost-effective? The upfront cost is higher than standard options. Long-term savings balance this. Less frequent replacements cut costs. Lower energy use and maintenance add to savings. It suits industries needing reliable water treatment. High efficiency justifies the initial investment.

(MBR Membrane High Flux Silicon Carbide Flat Sheet Ceramic Membrane for Water Treatment)

REQUEST A QUOTE

RELATED PRODUCTS

RBSIC/SISIC Silicon Carbide Ceramic Screw Thread Tube SISIC Roller for Ceramic Kiln

Advanced Industrial Grade MXene Ti3SiC2 Titanium Silicon Carbide Powder MAX Phase Ceramic Material

High Strength Industrial Ceramic Porous Metal Filtration Black Silicon Carbide Ceramic Foam Filter Plate

Customized Mirror Polished Silicon Carbide (RBSIC/SSIC) Ceramic Seal Ring for High Temperature Mechanical Seals

Tactical Vest Aluminum/Silicon Carbide Plate Hard Armor IIIA/III/IV Ceramic Personal Defense Strike Face Hard Tactical Plate