Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

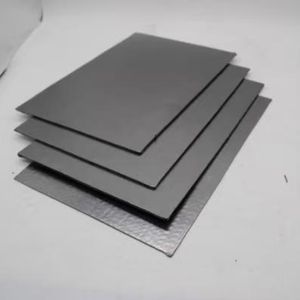

Overview of Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic

Silicon Carbide (SiC) ceramics are renowned for their outstanding mechanical properties, including high hardness, strength at elevated temperatures, and excellent thermal shock resistance. These materials are pivotal in cutting-edge industrial applications, from abrasives to aerospace components, due to their unique combination of properties.

Features of Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic

High Hardness: Exceptional wear resistance.

Thermal Shock Resistance: Can withstand rapid temperature changes.

Chemical Stability: Resistant to most chemicals.

High Thermal Conductivity: Efficient heat dissipation.

Low Density: Lightweight for its strength.

(Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic)

Specification of Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic

This silicon carbide ceramic ring is a high-performance insulating part. It manages extreme problems reliably. Made from pure sintered silicon carbide, it provides extraordinary solidity. This product is nearly as difficult as diamond. It stands up to wear exceptionally well. You obtain long life span even in rough setups.

Heat resistance is superior. This ring runs continually at 1600 ° C(2912 ° F). Brief bursts get to even 1800 ° C (3272 ° F). Thermal shock resistance is superb. Abrupt temperature level adjustments will not split it. It heats up and cools rapidly without damage. This security is crucial for demanding processes.

Chemical resistance is exceptional. Acids, alkalis, and molten salts cause minimal result. It stands up to rough furnace ambiences. Deterioration is rarely a trouble. This makes it suitable for chemical processing and metallurgy.

Electric insulation properties are solid. It provides trusted insulation at high voltages. It functions well in high-frequency applications. Reduced thermal expansion guarantees stable dimensions. Size remains consistent under extreme heat.

These rings serve essential functions. They function as furnace linings, assistance light beams, and heating element insulators. They are utilized in kiln furniture, heater nozzles, and thermocouple security tubes. Semiconductor making depends on them. Foundries and warmth treatment stores utilize them thoroughly. They are important in aerospace part testing. Their resilience decreases downtime and replacement expenses.

(Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic)

Applications of Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic

Silicon carbide ceramic rings are insulating elements made from a special material. This material is silicon carbide, frequently called SiC. It is a technical ceramic. These rings provide exceptional homes for tough jobs. They take care of really high temperatures easily. Several other materials stop working under such warmth. SiC rings stay solid and stable. They give leading degree electric insulation also. This protects against unwanted present circulation. It keeps equipment safe.

Their hardness is an additional essential advantage. SiC is incredibly tough. This makes the rings very resistant to use. They last a very long time also in harsh problems. They stand up to chemical attack well too. Lots of extreme acids and bases don’t damage them. This chemical stability is essential in lots of procedures.

These buildings make SiC rings important sought after markets. Semiconductor making uses them heavily. They shield wafer handling equipment. They shield sensitive parts from severe warm and plasma. Heater home builders depend on them. SiC rings function as high-temperature insulation liners. They separate warm zones securely. They sustain heating elements safely.

Power electronics profit substantially. SiC rings protect high-power gadgets. They take care of warm effectively in converters and inverters. This enhances device reliability and life-span. Industrial heater utilize these rings. They shield components in heaters and kilns. They guarantee effective warmth transfer happens. They stop electric shorts accurately.

The aerospace field values SiC rings. Jet engines and rocket parts encounter extreme heat. SiC rings offer insulation where needed. They hold up against the punishing setting. Chemical processing plants utilize them. They take care of corrosive fluids and high temperatures. They maintain honesty where metals corrode. Automotive applications are expanding. Electric lorries need durable power electronics. SiC rings aid handle heat and electrical power in these systems.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic

What makes silicon carbide rings different from other ceramics?

Silicon carbide handles extreme heat very well. It moves heat away fast. This stops equipment from overheating. It stays strong under high temperatures. Other ceramics crack or wear out quicker here.

Where are these rings usually used?

You see them in high-heat industrial jobs. They insulate electric furnaces and kilns. They work in semiconductor making equipment. They protect parts in steel processing lines. Any place needing heat control uses them.

How hot can these rings safely get?

They manage temperatures up to 1600°C continuously. Short bursts can hit 1750°C. This is much hotter than many metals or plastics handle. They keep their shape and strength near their limit.

Do these rings break easily under stress?

No, they are very tough. Silicon carbide resists thermal shock extremely well. Sudden temperature changes won’t shatter them. They also resist wear and chemical corrosion. This gives them a long working life.

Is installing these rings difficult?

Handle them carefully during setup. Avoid sharp impacts or drops. They are hard but can chip if hit wrong. Make sure surfaces fit flush. Follow the maker’s torque specs for any bolts. Proper installation prevents early failure.

(Tenical Ceramic Ring Silicon Carbide Insulating Component Sic Ceramic)

REQUEST A QUOTE

RELATED PRODUCTS

SIC Mechanical Seal Ring Stationary SSiC Silicon Carbide Ceramic Ring

Silicon Carbide Ceramic Tube SIC Bushing

SIC Industrial Ceramic Sinter High Temperature Graphite Heating Elements 2400 Degree Silicon Carbide Vacuum Sintering Furnace

High Quality Super Hexagon Silicon Carbide Ceramic Tile Plate

0.4mm-100mm G10 Ceramic Balls Silicon Carbide Ball Sic for Bearings Sic Ceramic Grinding Ball