Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

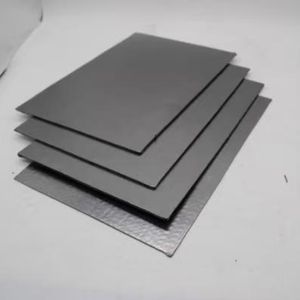

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications)

Specifications of B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications

B-Si3N4 beta silicon nitride (CAS 12033-89-5) is a high-grade ceramic basic material developed for demanding refractory applications. This sophisticated substance integrates silicon nitride (Si3N4) with zirconia (ZrO2) to improve mechanical stamina, thermal security, and resistance to harsh settings. Its distinct residential properties make it perfect for markets needing sturdy products under extreme problems.

The material includes a high pureness degree going beyond 99%, decreasing contaminations that could compromise performance. Bit sizes range from 0.5 to 2.0 micrometers, ensuring consistent blending and thick sintering. This fine bit distribution improves structural honesty in completed items. A mass thickness of 3.2– 3.4 g/cm four contributes to superior wear resistance, extending service life in abrasive setups.

B-Si3N4 maintains security at temperature levels up to 1600 ° C, standing up to deformation and thermal shock. This makes it ideal for parts subjected to fast home heating or cooling cycles. It shows superb chemical inertness, enduring deterioration from acids, alkalis, and molten metals. Such resistance is critical in metallurgical or chemical processing tools.

Applications include heater linings, kiln furnishings, and crucibles for steel melting. It is likewise used in protective finishings for generators, engine components, and commercial tools. The product’s integrity in high-stress atmospheres supports its usage in aerospace, auto, and power sectors.

Processing B-Si3N4 involves basic ceramic production methods like pushing, extrusion, or shot molding. Compatibility with these techniques allows cost-efficient manufacturing of intricate shapes. The raw product is provided as a great powder, all set for blending with binders or additives based upon details requirements.

Storage space recommendations consist of keeping the powder in a completely dry, awesome atmosphere to stop wetness absorption. Correct handling guarantees constant performance during construction. Producers prioritize this material for its equilibrium of sturdiness, heat resistance, and versatility to industrial procedures.

(B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications)

Applications of B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications

Beta silicon nitride (B-Si3N4) incorporated with zirconia ceramic resources (CAS 12033-89-5) works as a high-performance option for requiring refractory applications. This composite product masters severe environments due to its unique homes. It remains steady at high temperatures, making it optimal for markets such as steelmaking, glass production, and metal processing. The mix of beta silicon nitride and zirconia guarantees lasting performance under thermal stress.

The product withstands oxidation and deterioration well. This is critical in heaters, kilns, and activators where direct exposure to hostile chemicals or gases is common. Its chemical inertness stops deterioration, prolonging the life-span of refractory linings. This minimizes maintenance costs and downtime for commercial tools.

Mechanical strength is one more vital benefit. B-Si3N4-zirconia compounds deal with hefty tons without fracturing or flawing. This resilience is essential for maintaining frameworks solid in high-wear areas like heater hearths or molten metal containers. The product’s durability ensures integrity in constant procedures.

Thermal shock resistance sticks out. Quick temperature level changes frequently damage typical refractories. This composite takes in abrupt shifts without damaging. It does reliably in processes needing fast heating or cooling down cycles, such as aerospace part manufacturing or semiconductor processing.

The material operates in diverse markets. Steel plants use it for ladles and tundishes. Glass manufacturers apply it in melting tanks. Chemical plants depend on it for reactor cellular linings. Its adaptability fulfills stringent efficiency criteria across markets.

Customizable grades deal with details needs. Adjusting the proportion of beta silicon nitride to zirconia tailors residential properties like thermal conductivity or firmness. This versatility supports specialized applications without jeopardizing efficiency.

CAS 12033-89-5 recognizes the raw product, making certain high quality and consistency. Makers trust this formula for critical refractory systems where failure is not a choice.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications

Beta silicon nitride (B-Si3N4) with CAS 12033-89-5 is a high-performance ceramic raw material. It is widely used in refractory applications. Below are answers to common questions about this product.

What is B-Si3N4?

B-Si3N4 is a ceramic compound made of silicon and nitrogen. It has a beta-phase crystal structure. This structure gives it high thermal stability. It works well in extreme temperatures.

Why use B-Si3N4 in refractory materials?

B-Si3N4 resists heat and wear. It keeps strength at temperatures over 1200°C. It handles thermal shocks without cracking. This makes it ideal for furnace parts or kiln linings.

How does B-Si3N4 compare to other ceramics?

B-Si3N4 lasts longer than alumina or zirconia in high-heat settings. It bonds better with zirconia. This improves toughness. It also resists oxidation better than many metals.

What industries use B-Si3N4 refractories?

Steelmaking and glass production rely on B-Si3N4. It is used in molten metal handling. Aerospace and automotive sectors use it for heat-resistant components.

How should B-Si3N4 raw materials be stored?

Store B-Si3N4 powder in dry conditions. Moisture causes clumping. Use sealed containers. Avoid direct sunlight. Handle with protective gear to prevent inhalation.

(B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications)

REQUEST A QUOTE

RELATED PRODUCTS

230W 300W Silicon Nitride Si3N4 Ceramic Igniter Black Quartz Crystal Heater Ighter Quartz Igniter

624CE Silicon Nitride Ceramic Bearing 624CE RS Factory Manufacturing Insulation Smooth Long Idling Ceramic Bearing 4*13*5mm

Superior Hardness Industrial Ceramics Si3N4 Silicon Nitride Ceramic Cutting Tool/ Blade/Knife

High Wear Resistant Silicon Nitride Ceramic Tube With 4 Holes

Zirconia and Silicon Nitride Ceramic Bearing 608 688 R188 6202