Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding)

Specifications of Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding

Gas Stress Sintering Silicon Nitride Ceramic Dowel Pins for Automobile Welding are developed for high-performance applications. These pins are made from silicon nitride ceramic product processed with gas pressure sintering. This method ensures high density and architectural uniformity. The pins are excellent for severe settings because of their remarkable thermal and mechanical homes.

Trick requirements include a diameter range of 3 mm to 20 mm. Length options vary from 10 mm to 100 mm. Custom-made dimensions are available for specialized needs. The product make-up is 99% pure silicon nitride. This assures resistance to oxidation and chemical deterioration. Operating temperature levels can reach up to 1200 ° C without loss of strength. Thermal shock resistance allows rapid heating or cooling without splitting.

The pins include a hardness degree of 90 HRA. This makes them appropriate for unpleasant conditions. Compressive strength goes beyond 2500 MPa. They maintain dimensional stability under heavy loads. Surface roughness is controlled listed below Ra 0.4 μm. This reduces friction and use throughout operation. Tight resistances of ± 0.01 mm make sure exact positioning in welding components.

Electric insulation residential or commercial properties avoid current leak in welding systems. The non-magnetic nature stays clear of disturbance with sensitive tools. Chemical inertness withstands acids, alkalis, and solvents usual in vehicle settings. These pins are compatible with automatic welding robotics and hand-operated setups.

Applications consist of finding and straightening elements in welding jigs. They safeguard parts during high-temperature welding procedures. Use instances include engine setting up, exhaust systems, and framework construction. The ceramic material eliminates steel contamination threats. This boosts weld high quality and consistency.

Benefits over metal dowel pins consist of longer life span. They do not rust or deteriorate in damp problems. Decreased upkeep reduces production downtime. Weight savings enhance efficiency in automated lines. Compatibility with high-speed welding procedures enhances efficiency.

Checking procedures consist of three-point bending tests and microstructural analysis. Each batch undergoes extensive quality checks. Accreditations satisfy ISO 9001 and auto sector requirements. Packaging alternatives consist of anti-static containers to avoid surface damage. Technical support is readily available for setup support.

These dowel pins address obstacles in contemporary car welding. They supply reliability sought after thermal and mechanical problems. Performance information sustains their usage in electrical vehicle manufacturing. Adjustable remedies satisfy certain welding procedure needs.

(Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding)

Applications of Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding

Gas stress sintering silicon nitride ceramic dowel pins are vital in auto welding procedures. These pins handle extreme problems usual in automobile production. The product’s high-temperature resistance permits it to do dependably in welding environments where steel parts get to intense warm. This minimizes deformation risks during welding operations.

The pins make sure accurate positioning of components. Automotive welding needs tight tolerances for security and performance. Silicon nitride’s hardness and reduced thermal development maintain components lined up accurately also under thermal anxiety. This avoids imbalance concerns that might endanger weld high quality.

Resilience is another vital advantage. Gas stress sintering creates a thick ceramic framework immune to put on and rust. Unlike metal pins, silicon nitride does not degrade from repeated exposure to warmth, sparks, or chemical byproducts. This extends life span and lowers substitute prices.

Electric insulation homes issue in welding applications. Silicon nitride does not perform electrical power. This prevents unexpected existing circulation throughout resistance welding or arc welding procedures. It enhances safety and security for devices and operators.

The lightweight nature of ceramic dowel pins streamlines handling in automated welding systems. Minimized weight lowers stress and anxiety on robotic arms and fixtures. This enhances functional efficiency in high-speed production lines.

Automakers make use of these pins in welding jigs, components, and robot assembly units. They are common in body-in-white welding for straightening car frameworks and panels. Laser welding systems likewise take advantage of their heat resistance and precision.

Silicon nitride’s compatibility with cleanroom atmospheres suits electrical lorry battery module welding. The product does not create particles or respond with sensitive battery components. This preserves tidiness in critical setting up stages.

Cost-effectiveness expands in time due to marginal upkeep needs. The pins stand up to staying with thaw steel splatter. This lowers downtime for cleansing or changes. Their dependability supports consistent outcome in mass production setups.

Customized sizes and shapes are possible with innovative sintering methods. Makers customize pin dimensions to certain welding setups. This adaptability addresses varied auto layout demands.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding

Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pins for Automobile Welding: 5 FAQs

What makes silicon nitride ceramic suitable for dowel pins in welding?

Silicon nitride ceramic resists high heat and wear. Automobile welding creates extreme temperatures. Metal pins often warp or degrade. Ceramic stays stable. Its hardness prevents scratches during alignment. This improves welding precision.

How does gas pressure sintering improve the ceramic’s quality?

Gas pressure sintering applies heat and pressurized gas to the material. This method removes tiny gaps inside the ceramic. The result is a denser, stronger pin. Dense structures handle stress better. This reduces cracks or breaks during heavy use.

Why choose ceramic dowel pins over metal ones?

Metal pins expand under heat. This causes misalignment in welding fixtures. Ceramic pins expand less. They keep their shape. Ceramic also lasts longer. It doesn’t rust or corrode like metal. Maintenance costs drop over time.

Can these pins handle repeated thermal shocks?

Yes. Silicon nitride cools and heats quickly without damage. Welding processes involve rapid temperature changes. Ceramic pins survive these cycles. Metal pins may weaken after repeated shocks. Ceramic stays reliable.

Are custom sizes or shapes available for specific welding setups?

Manufacturers offer customization. Gas pressure sintering allows precise control during production. Pins can match unique fixture designs. Custom options ensure compatibility with different automobile parts. Specifications like diameter or length are adjustable.

This product suits high-precision welding applications. Its durability and heat resistance address common issues in automotive manufacturing. Users report fewer replacements and improved welding accuracy.

(Gas Pressure Sintering Silicon Nitride Ceramic Dowel Pin for Automobile Welding)

REQUEST A QUOTE

RELATED PRODUCTS

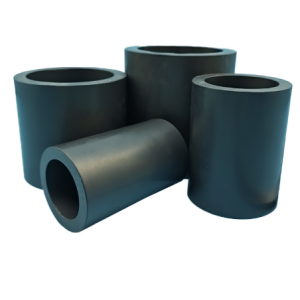

Silicon Nitride Tube High Hardness And High Strength Si3N4 Tube

B-Si3N4 Beta Silicon Nitride Si3N4 Zirconia Ceramic Raw Materials with CAS 12033-89-5 for Refractory Applications

0.8mm Silicon Nitride Si3N4 Ceramic Diff Balls

Factory Direct Wear Resistance Ceramic Beads 0.4-0.6mm Silicon Nitride Industrial Ceramic Balls

Best Quality High Hardness 3.175mm 5.556mm 6.35mm 7.935mm 9.525mm Zirconia Silicon Nitride Ceramic Balls