Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

(High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm)

Specifications of High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm

High Solidity Silicon Nitride Si3N4 Ceramic Rounds provide premium efficiency popular commercial applications. These accuracy ceramic spheres can be found in several sizes: 6mm, 6.35 mm (1/4 inch), 7mm, 7.144 mm (9/32 inch), and 7.938 mm (5/16 inch). The material makes sure remarkable longevity because of its high hardness rating of roughly 15-16 Grade point average on the Vickers range. This residential or commercial property makes them resistant to put on, reducing replacement frequency in equipment.

Silicon nitride ceramic balls keep secure performance under severe conditions. They operate successfully in temperature levels ranging from -40 ° C to 1,200 ° C. This thermal stability protects against contortion or fracturing throughout quick temperature shifts. The material’s low density (3.2-3.3 g/cm TWO) reduces rotational inertia, improving performance in high-speed bearings.

These ceramic spheres stand up to chemical corrosion from acids, antacid, and solvents. This makes them suitable for harsh settings like chemical processing equipment or marine applications. Their electrical insulation homes avoid present leak in electric systems, enhancing safety and security.

Surface area coating top quality meets rigorous criteria, with roughness worths below 0.02 microns. This minimizes rubbing in precision bearings, prolonging part life expectancy. Each batch goes through extensive screening for dimensional precision, sphericity, and compressive strength.

Typical applications consist of aerospace bearings, automobile turbochargers, clinical gadgets, and high-performance equipment. Compared to steel balls, silicon nitride variations lower weight by 60% while providing higher tiredness resistance.

Custom-made sizes and resistances are offered for specialized requirements. The product follows international criteria such as ISO 3290 for bearing parts. Product packaging choices include anti-static containers to avoid surface area contamination during transport.

Material pureness surpasses 99%, with minimal porosity to make certain structural integrity. X-ray evaluation and ultrasonic screening confirm inner uniformity. These quality checks guarantee trusted performance in mission-critical systems.

The ceramic spheres work in mix with steel or ceramic races. Proper installation guidelines are offered to optimize efficiency. Technical support assists with material selection based upon tons capacity, speed, and ecological elements.

Supply includes basic grades for basic usage and high-precision grades for specialized applications. Lead times vary based upon order volume and personalization requirements. Bulk pricing discount rates apply for industrial-scale purchases.

(High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm)

Applications of High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm

High hardness silicon nitride Si3N4 ceramic rounds in dimensions like 6mm, 6.35 mm, 7mm, 7.144 mm, and 7.938 mm are extensively made use of in industries calling for severe longevity and precision. These spheres are made from sophisticated ceramic materials. They offer high stamina, use resistance, and thermal stability. These properties make them excellent for requiring applications.

In automobile systems, Si3N4 ceramic spheres are made use of in bearings for turbochargers and gas injection systems. Their low thickness decreases rubbing. This improves gas efficiency. They manage high-speed rotations without degrading. This extends element life. The 6.35 mm and 7mm dimensions are common below.

Aerospace applications depend on these ceramic balls for crucial parts like turbine engines and navigating systems. They carry out well in high-temperature environments. They withstand thermal shock. This ensures dependability during fast temperature level adjustments. The 7.144 mm and 7.938 mm dimensions fit accuracy aerospace parts.

Industrial machinery makes use of Si3N4 spheres in pumps, compressors, and grinding devices. Their hardness lowers wear in rough problems. This reduces maintenance prices. The 6mm and 7mm sizes are preferred for machinery bearings. They maintain dimensional stability under heavy lots.

Clinical tools gain from these ceramic balls because of their biocompatibility and corrosion resistance. They are made use of in dental devices and medical tools. The smooth surface area lessens particle generation. This is important for sterilized atmospheres. Dimensions like 6.35 mm and 7mm satisfy rigorous medical standards.

Electronics making usages Si3N4 rounds in accuracy adapters and sensing units. Their electric insulation residential properties avoid short circuits. They hold up against extreme chemicals. This makes them suitable for semiconductor processing devices. Smaller sized sizes like 6mm guarantee precision in fragile settings up.

These ceramic spheres are likewise utilized in energy industries like wind generators and atomic power plants. They sustain high stress and radiation direct exposure. This decreases downtime. The 7.938 mm size is typically chosen for large-scale energy systems.

High hardness silicon nitride ceramic spheres supply long-lasting efficiency across sectors. Their versatility in size and residential or commercial properties supports technology in innovation and design.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm

High Hardness Silicon Nitride Si3N4 Ceramic Balls are precision components used in industrial applications. Below are answers to common questions about these products.

1. What are High Hardness Silicon Nitride Ceramic Balls?

These balls are made from silicon nitride, a ceramic material known for extreme hardness. They resist wear, heat, and corrosion. The material is non-metallic, making them ideal for environments where metal parts fail. Common uses include bearings, valves, and pumps.

2. Why choose silicon nitride balls over steel or zirconia?

Silicon nitride offers better performance in harsh conditions. They are lighter than steel, reducing friction. They handle higher temperatures than zirconia. Their hardness prevents deformation under heavy loads. They last longer in abrasive or high-speed applications.

3. What sizes are available?

Standard diameters include 6mm, 6.35mm, 7mm, 7.144mm, and 7.938mm. Custom sizes are possible. These sizes fit common industrial equipment like bearings and grinding mills. Precision grinding ensures consistent roundness and surface finish.

4. How do these balls perform in high-temperature environments?

Silicon nitride maintains strength at temperatures up to 1,200°C. They do not expand or soften like metals. This stability prevents machinery failure in furnaces, engines, or aerospace systems. Thermal shock resistance allows sudden temperature changes without cracking.

5. Are these ceramic balls suitable for corrosive chemicals?

Yes. Silicon nitride resists acids, alkalis, and solvents. They outperform metals in chemical processing or marine settings. No rust or degradation occurs. This makes them reliable for pumps, valves, or medical devices exposed to aggressive fluids.

These ceramic balls reduce downtime and improve efficiency in demanding applications. They are tested for quality, ensuring they meet industry standards for hardness, density, and fracture toughness. Proper handling avoids chipping during installation.

(High Hardness Silicon Nitride Si3N4 Ceramic Balls 6mm 6.35mm 7mm 7.144mm 7.938mm)

REQUEST A QUOTE

RELATED PRODUCTS

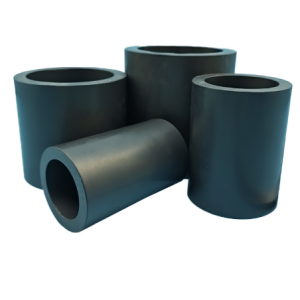

Wear Resistant Customized Si3n4 Silicon Nitride Ceramic Bushing

Industrial Square Silicon Nitride Ceramic Block Plate Si3N4 Sheet

Custom Silicon Nitride Ceramic Cutter Custom Ceramic Pieces Special Ceramic Pieces Silicon Nitride Welding Ruler

Wear and Corrosion Resistant Black Ceramic for Industry Silicon Nitride Ceramic Piston

High Pressure Resistant Si3N4 Silicon Nitride Ceramic Plunger for Welding