Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Silicon Nitride Ceramics

Silicon Nitride Ceramics are high-performance materials known for their excellent mechanical properties, including strength, toughness, and resistance to wear, corrosion, and thermal shock, making them ideal for demanding applications in various industries.

Features of Silicon Nitride Ceramics

Exceptional hardness and wear resistance.

Superior mechanical strength and fracture toughness.

Excellent thermal stability and resistance to thermal shock.

High corrosion resistance in aggressive environments.

Low density contributing to lightweight components.

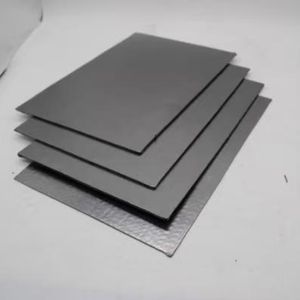

(Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate)

Specifications of Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate

Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Porcelain Disc Plate is designed for high-performance industrial applications. The product integrates stamina, durability, thermal stability. It suits atmospheres requiring resistance to severe heat, wear, deterioration.

The plates come in conventional dimensions. Usual density arrays from 3mm to 50mm. Diameters range 10mm to 500mm. Custom-made measurements are available. Shade is usually grayish-black. Surface area finish is smooth, with roughness below 0.8 μm. Tolerances are tight, ensuring precision in machining.

Silicon nitride (Si3N4) ceramic has low thickness. It considers around 3.2 g/cm ³. This makes it lighter than steel. It reduces element weight in equipment. The solidity is high, measuring 85-90 HRA. It withstands abrasion properly. Flexural toughness exceeds 600MPa. Fracture toughness is 6-7 MPa · m ONE/ ². These buildings protect against cracking under stress.

Thermal stability is a key function. Home plates handle temperatures approximately 1200 ° C in air. In inert atmospheres, they hold up against 1800 ° C. Thermal development is reduced, minimizing shape adjustments during heating. Thermal conductivity is moderate, around 20-30 W/m · K. This equilibriums warm circulation. Thermal shock resistance is excellent. Fast temperature shifts trigger no damage.

Electrical insulation homes are strong. Volume resistivity mores than 10 ¹⁴ Ω · cm at room temperature level. It continues to be steady even at heats. This avoids existing leak. The product resists oxidation. It does well in corrosive gases or molten metals.

Applications consist of aerospace components, vehicle engine parts, metal developing tools. It works as welding rollers, furnace fixtures, semiconductor processing components. The plates are made use of in pump seals, bearings, cutting tools. They replace metal alloys in high-wear circumstances.

Customization choices include openings, grooves, finishes. Machining services guarantee exact fits. Home plates are tested for high quality. Each batch goes through checks for fractures, thickness, dimensions. Product packaging makes use of anti-static materials. Handling guidelines prevent chipping.

Silicon nitride ceramic plates provide long service life. They lower downtime in commercial systems. Performance stays constant under mechanical or thermal stress. Upkeep expenses stay low. Compatibility with harsh chemicals is ensured.

(Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate)

Applications of Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate

Refractory ceramic plates made from silicon nitride (Si3N4) are made use of in numerous industries due to their solid efficiency under difficult conditions. These plates take care of high heat well, making them perfect for heaters, kilns, and metal handling tools. They keep their shape and toughness also at temperatures over 1200 ° C, so they last much longer than traditional products like steel or alumina.

In commercial equipment, silicon nitride layers job as wear-resistant components. They minimize rubbing in bearings, cutting tools, and engine elements. Their solidity and low thermal expansion mean they endure hefty loads and repeated use without splitting. This reduces downtime and upkeep expenses in making setups.

The electronics industry makes use of these plates for their electric insulation and thermal conductivity. They help cool down high-power tools like LED components and semiconductor chips. Their capability to transfer warmth while obstructing electric present enhances gadget reliability and lifespan.

Clinical devices also gains from silicon nitride plates. They are biocompatible, so they work safely in implants and medical tools. Their resistance to chemicals and germs makes them appropriate for sanitation processes.

Aerospace and energy markets depend on these plates for parts revealed to extreme stress and anxiety. They are utilized in generator blades, heat exchangers, and elements for solar or nuclear systems. Their light-weight nature and toughness help improve performance sought after atmospheres.

Silicon nitride ceramic discs are personalized in size and shape. They are made with advanced sintering procedures to guarantee thickness and purity. This adaptability permits them to fulfill certain requirements throughout different applications.

These plates are a functional selection for sectors needing products that combine heat resistance, mechanical stamina, and chemical stability. Their convenience supports innovation in technology and design without compromising efficiency.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate

What is a Si3N4 ceramic plate?

A Si3N4 ceramic plate is made from silicon nitride. This material combines high strength with light weight. It handles extreme heat and resists wear. These plates work in tough conditions like high temperatures or heavy mechanical stress. Industries use them where metals or other ceramics fail.

How much heat can these plates handle?

Silicon nitride plates handle up to 1,200°C (2,192°F) continuously. Short-term exposure can go higher. The material keeps its shape and strength under heat. This makes it ideal for furnaces, welding tools, or engines. It cools down fast without cracking.

Where are these plates commonly used?

They appear in metal processing, aerospace, automotive, and electronics. Examples include furnace linings, cutting tools, turbine components, and semiconductor equipment. Their heat resistance and durability suit high-stress environments. They also reduce energy loss in thermal systems.

Are Si3N4 plates durable?

Yes. Silicon nitride outperforms alumina or zirconia in toughness. It resists scratches, impacts, and chemical corrosion. These plates last longer in abrasive or corrosive settings. Maintenance costs drop because replacements happen less often.

Can I get custom sizes or shapes?

Manufacturers offer custom dimensions, thicknesses, and surface finishes. Precision machining ensures tight tolerances. Specific needs like holes or grooves are possible. Custom designs match unique equipment or industrial processes.

(Refractory Ceramic Plate Si3N4 Plates Silicon Nitride Ceramic Disc Plate)

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Gray Silicon Nitride Ceramic Rings Bending Processed Guide Rings for Fishing Rod for Refractory Structure Ceramic

Custom Silicon Nitride Ceramic Rod Polished High Purity Silicon Carbide Nitride Si3N4 Ceramic Rod

0.4mm-100mm G5-G40 Ceramic Balls Silicon Nitride Ball Si3n4 For Bearings Ceramic Bead Si3n4 Ball

Hard High Polished Si3N4 Silicon Nitride Ceramic Long bar Rod

1.0-1.2mm Silicon Nitride Ball Beads Industrial Ceramic Si3N4 Ball Wear Resistance