Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

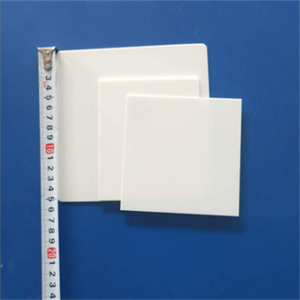

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics)

Specifications of Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics

Australia Imported Material Zirconia Powder Porcelain Zirconium Powder Sand is a high-quality material developed for innovative ceramic applications. It is sourced from relied on providers in Australia, making sure consistent performance and dependability. This zirconia powder is ideal for commercial and creative ceramic manufacturing, offering superb durability and heat resistance.

The powder has a purity degree of 99.5% or greater, minimizing impurities that can impact final product quality. Its bit dimension varies from 0.1 to 50 microns, permitting precise control over appearance and thickness in ceramics. The consistent particle circulation improves sintering performance, causing more powerful finished products.

This zirconium powder sand is chemically secure. It stands up to corrosion and oxidation also under heats, making it ideal for extreme atmospheres. The product has a high melting factor of approximately 2715 ° C, making certain structural honesty in high-heat applications like heating system linings or aerospace components.

The product is compatible with numerous shaping approaches, including dry pushing, injection molding, and slip spreading. It bonds well with other ceramic materials, enabling personalized blends for particular task requirements. The powder’s reduced wetness content minimizes fracturing during drying and firing procedures.

Product packaging choices include 25 kg secured bags or mass containers, all created to prevent contamination. Storage space recommendations highlight keeping the powder in a completely dry, awesome setting to preserve its residential properties. Custom packaging is available for large orders.

Applications extend dental porcelains, industrial finishings, refractory materials, and electronic parts. In oral use, the powder ensures biocompatibility and visual charm for crowns and implants. For commercial uses, it enhances wear resistance in equipment parts.

Technical specifications include a density of 5.68 g/cm ³ and a solidity of 8.5 on the Mohs scale. The product fulfills worldwide standards for hefty metal material, ensuring safety and security in consumer products. Batch screening assurances regular quality throughout all shipments.

The powder is available in both calcined and uncalcined forms, satisfying different manufacturing stages. Consumer assistance assists with technical inquiries, aiding users enhance material usage for their particular processes. Preparations differ based on order quantity, with basic deliveries dispatched within 7 business days.

(Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics)

Applications of Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics

Australian imported zirconia powder ceramic zirconium powder sand offers numerous markets. This material works well in innovative ceramic production. Suppliers use it to produce solid, heat-resistant components. High-purity zirconia powder guarantees steady efficiency in severe problems. Its chemical stability makes it optimal for rough settings.

The electronic devices market depends on this powder for protecting parts. Components like sensors or circuit boards gain from its longevity. Zirconia’s low thermal conductivity helps handle heat in devices. This decreases failure risks in high-temperature applications.

Aerospace and automotive industries use zirconia-based porcelains for engine components. The product endures intense warmth and wear. This prolongs the lifespan of wind turbines or exhaust systems. Its resistance to rust makes it suitable for parts revealed to chemicals.

Clinical fields apply zirconia powder in dental implants and prosthetics. The material’s biocompatibility stops being rejected in the body. It simulates all-natural teeth in look and toughness. Surgeons utilize zirconia devices for their accuracy and sterility.

Musicians and engineers choose zirconium sand for refractory layers. It shields surface areas in heating systems or reactors. The sand’s great grain allows smooth application. This develops even layers that resist cracking under stress and anxiety.

Australian resources guarantee top notch resources. Stringent quality assurance ensures uniformity in bit size and pureness. Providers examine each batch for contaminants. This satisfies international criteria for industrial use.

The powder’s flexibility sustains customized remedies. Makers readjust grain dimension or additives for details needs. This flexibility fits small laboratories and huge factories.

Zirconia porcelains decrease upkeep expenses gradually. Their longevity offsets first financial investment. Industries save sources by reducing substitutes.

Environmental applications consist of filters for contamination control. Zirconia-based filters catch hazardous fragments in discharges. This help compliance with ecological regulations.

The material’s non-reactive nature suits food handling tools. It prevents contamination in production lines. Heat-resistant zirconia parts manage sterilisation processes.

International demand expands as markets look for trustworthy materials. Australian zirconia powder stands out for top quality and versatility. Its role in advancement drives progress throughout sectors.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics

What is Australia Imported Zirconia Powder Ceramic Zirconium Powder Sand?

This material is a high-quality ceramic powder sourced from Australia. It is made from zirconium dioxide (ZrO2). The powder is fine, pure, and heat-resistant. It is used mainly in ceramics, dental products, and industrial applications. Its stability under high temperatures makes it ideal for demanding environments.

What are the common uses of this zirconia powder?

The powder is used to create strong ceramic parts like tiles, tableware, and decorative items. Dental labs use it for crowns and bridges due to its durability. Industrial applications include coatings for machinery parts exposed to heat or wear. It is also added to glass and enamel to improve strength.

How does this powder compare to other ceramic materials?

Zirconia powder has higher fracture toughness than many ceramics. It resists cracks better under stress. Its thermal stability allows it to handle rapid temperature changes without damage. Unlike some materials, it does not corrode easily. This makes it last longer in harsh conditions.

Is this material safe to handle?

The powder is safe when handled correctly. Wear protective gear like masks and gloves to avoid inhaling particles or skin contact. Store it in a dry, cool place away from moisture. Follow local disposal guidelines to prevent environmental harm.

Where can I buy genuine Australian-imported zirconia powder?

Purchase directly from certified suppliers or industrial material distributors. Check for quality certifications like ISO standards. Some online platforms specialize in ceramic raw materials. Verify the supplier’s reputation and request product test reports before buying.

(Australia Imported Material Zirconia Powder Ceramic Zirconium Powder Sand for Ceramics)

REQUEST A QUOTE

RELATED PRODUCTS

Good Size Dental Powder for 3D Printing Yttrium Stabilized Zirconia ZrO2 Ceramic

Dental Ceramic Zirconia Block CAD/CAM Open System 98mm Disk Dental Laboratory Materials

94.7% ZrO2 5.2% Y2O3 Yttrium Stabilized Zirconia Ceramic Tetragonal Phase, Used for Oxygen Sensors and Fine Ceramics

Dental Lab Stain And Glaze Zirconia Crowns Ceramic Glaze Powder Paste Glaze Paste

Zirconia Heating Elements Double Spiral Heater Heating Element Ceramic Sic Carbide Heater