Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

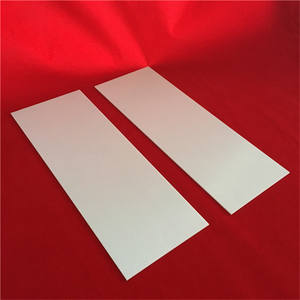

(Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade)

Specifications of Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade

This cutting blade is made from high-quality zirconia (ZrO2) ceramic. It is designed for heavy-duty cutting tasks. The trapezoid shape improves stability during operation. It reduces vibration and enhances precision. The material offers excellent wear resistance. This ensures long-lasting performance even under tough conditions. The blade maintains sharpness over time. It minimizes the need for frequent replacements.

The zirconia ceramic structure provides high hardness. It ranks above traditional steel blades in durability. The blade resists corrosion and chemical damage. It works well in wet or dry environments. It handles high heat well. This prevents warping or degradation during extended use. The trapezoid design allows smooth material feed. It reduces friction and heat buildup. This helps protect both the blade and the workpiece.

This blade suits cutting hard materials. Examples include metals, composites, and reinforced plastics. It is ideal for industrial applications. Industries like construction, metalworking, and electronics benefit from it. The edge stays sharp after repeated use. This lowers downtime for blade changes. The ceramic material is non-conductive. It adds safety when working with electrical components.

Custom sizes and thicknesses are available. Common dimensions range from 50mm to 300mm in diameter. Thickness options vary between 0.5mm and 3mm. The blade fits standard cutting machines. Compatibility includes CNC equipment and handheld tools. Installation is straightforward. No special modifications are needed.

Maintenance requirements are minimal. Clean the blade regularly to remove debris. Avoid impacts on hard surfaces. Store it in a dry place when not in use. Proper care extends service life further. The blade’s toughness makes it cost-effective. It outperforms traditional options in lifespan and efficiency.

Users report consistent cutting results. The blade reduces material waste. It delivers clean edges without burrs. This improves the quality of finished products. Performance remains reliable across different speeds. It handles both high and low RPM settings. The design balances cutting aggressiveness with control. Operators achieve accurate cuts with minimal effort.

Safety features include reduced spark generation. This lowers fire risks in flammable environments. The lightweight design eases handling. It reduces operator fatigue during long tasks. The blade’s composition meets industrial safety standards. It is free from hazardous materials.

Warranty coverage depends on the supplier. Most offer guarantees against manufacturing defects. Bulk purchasing options are available for large-scale operations. Prices vary based on size and quantity. The blade’s durability ensures a strong return on investment.

(Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade)

Applications of Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade

The Excellent Wear Resistance Zirconia ZrO2 Ceramic Trapezoid Cutting Blade is designed for demanding industrial applications. This blade uses advanced zirconia ceramic material. The high hardness and toughness make it ideal for cutting tasks requiring precision and durability. The trapezoid shape enhances stability during operation. It reduces vibration and improves cutting accuracy.

This blade excels in environments where wear resistance is critical. It resists abrasion better than traditional metal blades. It maintains sharp edges longer. This reduces the need for frequent replacements. Industries like textiles, automotive, and electronics benefit from its performance. It cuts materials such as carbon fiber, fiberglass, reinforced plastics, and thin metals effectively.

Zirconia ceramic’s chemical inertness prevents corrosion. The blade performs well in harsh conditions. Exposure to acids, alkalis, or high temperatures does not degrade its structure. This ensures consistent performance over time. The material’s low thermal conductivity minimizes heat buildup during cutting. It protects sensitive materials from damage caused by excessive heat.

The trapezoid design distributes cutting force evenly. This reduces stress on the blade’s edges. It extends the blade’s lifespan. Users achieve cleaner cuts with minimal material waste. The blade fits standard cutting equipment. No special modifications are required for installation.

Cost efficiency is a key advantage. Longer service life lowers downtime and maintenance costs. Reduced replacement frequency saves resources. The blade’s lightweight nature decreases operator fatigue during prolonged use. It is suitable for high-volume production lines.

Applications include precision cutting in aerospace components, electronic circuit boards, and composite materials. It handles intricate shapes without chipping or cracking. The combination of wear resistance and structural integrity makes it reliable for repetitive tasks. Its versatility supports diverse industrial needs.

The blade’s performance is tested under rigorous conditions. It meets standards for industrial safety and efficiency. Users report improved productivity and reduced operational costs. This product is a practical solution for industries prioritizing quality and durability in cutting tools.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade

What makes the Excellent Wear Resistance Zirconia ZrO2 Ceramic Trapezoid Cutting Blade last longer than regular blades? The blade uses zirconium dioxide (ZrO2), a material known for hardness and toughness. The high-density structure resists friction and wear during cutting. This reduces material loss over time. It maintains sharpness longer than metal or standard ceramic blades.

How does the material composition improve performance? ZrO2 ceramic is the primary component. It includes additives like yttrium oxide for stability. The mix increases fracture resistance and thermal shock tolerance. The blade handles high-speed cutting without cracking. It stays effective in high-temperature environments.

Why is the trapezoid shape important? The trapezoid design spreads cutting force evenly across the blade edge. This prevents uneven wear and reduces chipping risks. The shape allows tighter cutting angles. It fits narrow spaces better than circular blades. Precision improves for detailed cutting tasks.

What materials can this blade cut effectively? It works on metals, ceramics, tiles, plastics, and composite materials. The wear-resistant edge stays sharp when cutting hard, abrasive surfaces. Avoid using it on materials harder than zirconia, like diamond-coated surfaces. Check compatibility before cutting unfamiliar materials.

How should users maintain the blade for maximum lifespan? Clean the blade after each use to remove debris. Avoid harsh chemicals that might weaken the ceramic. Inspect for chips or cracks before reuse. Store in a dry place to prevent moisture damage. Replace the blade if cutting efficiency drops noticeably.

(Excellent Wear Resistance Zirconia Zro2 Ceramic Trapezoid Cutting Blade)

REQUEST A QUOTE

RELATED PRODUCTS

Customizable High-precision Colored Industrial Ceramics.Alumina Ceramic.zirconia Ceramic

Industrial Grade Zirconia Powder High Purity ZrO2 Fused Stabilized Zirconium Powder for Ceramic

Ceramic Rod/zirconia Ceramic/smooth Ceramic

High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From

High Purity Zirconium Oxide Powder (zro2) Nano Ceramic Zirconia Powder for Electrostatic Coatings