Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

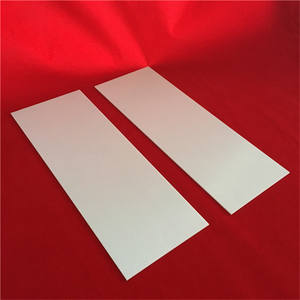

(High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk)

Specifications of High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk

High Solidity Zirconia Porcelain Block With Hole is a long lasting industrial product developed for requiring applications. Made from zirconium dioxide (ZrO2), it offers remarkable firmness, use resistance, and thermal security. The block features a precision-drilled opening, enabling very easy integration right into mechanical systems requiring placement, mounting, or liquid circulation.

The product composition makes sure high chemical inertness, making it resistant to acids, antacid, and harsh environments. It operates efficiently in temperature levels as much as 1500 ° C, preserving structural honesty under extreme warmth. The dense, non-porous surface lessens friction, reducing wear in high-contact applications like bearings, shutoffs, or reducing devices.

Requirement measurements range from 10mm to 200mm in size, width, and thickness, with opening sizes adjustable between 1mm and 50mm. Tolerances are tightly managed, usually within ± 0.05 mm, making sure compatibility with precision equipment. Personalized dimensions and opening configurations are readily available to satisfy certain job needs.

The ceramic block’s high crack strength prevents cracking under mechanical anxiety, outperforming standard materials like alumina or silicon carbide. Its reduced thermal conductivity decreases warmth transfer, perfect for insulation parts. Electric insulation properties make it suitable for electronic or high-voltage atmospheres.

Surface surfaces vary from as-sintered to brightened, with roughness degrees (Ra) in between 0.1 µm and 1.6 µm. Polished options lower abrasion in relocating parts. The hole sides are chamfered to avoid damaging during setup.

Applications consist of aerospace elements, chemical handling equipment, medical gadgets, and semiconductor manufacturing. It changes steel components in high-wear situations, prolonging service life and lowering upkeep costs.

Quality assurance includes strenuous testing for density (≥ 6.0 g/cm TWO), firmness (≥ 1200 HV), and flexural toughness (≥ 800 MPa). Each set goes through dimensional checks and visual inspections.

The item works with typical machining processes for post-processing. It is packaged in anti-static materials to prevent contamination. Lead times differ based on modification, with typical dimensions shipped within 5-7 service days.

This zirconia ceramic block integrates advanced product residential properties with functional layout, dealing with obstacles in extreme functional settings. Its reliability and versatility make it a preferred choice for designers seeking lasting performance services.

(High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk)

Applications of High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk

High solidity zirconia ceramic blocks with holes, zirconia ceramic blocks, and ZrO2 ceramic pieces are innovative materials made use of in different industries. These items are made from zirconium dioxide (ZrO2), a material known for its outstanding sturdiness, heat resistance, and chemical stability. Their high firmness makes them appropriate for applications where wear resistance and lasting performance are important.

The ceramic blocks with holes are frequently utilized in commercial equipment. They work as elements in pumps, valves, and bearings. The openings allow fluids or gases to travel through while preserving structural honesty. Their resistance to rust and high temperatures makes them excellent for harsh atmospheres like chemical handling plants or high-temperature heaters.

Zirconia ceramic bricks are widely made use of in electronic devices and production. They serve as protecting products in circuits, sensors, and burner. Their low thermal conductivity protects against heat loss, boosting energy efficiency. In steel developing, these blocks work as durable molds or cutting devices. Their smooth surface decreases rubbing, ensuring precision in shaping steels or plastics.

ZrO2 ceramic portions are used in clinical tools and aerospace. In health care, their biocompatibility makes them suitable for oral implants and medical devices. They withstand microbial development and withstand repeated sterilization. Aerospace markets utilize them for elements like wind turbine blades or thermal barrier. Their lightweight nature and capability to manage severe stress and anxiety improve airplane efficiency.

These ceramics are valued for their mechanical strength. They hold up against hefty tons without breaking. Their density and tight molecular framework avoid contamination in sensitive procedures. Personalized shapes and opening patterns are offered to satisfy specific needs.

The material’s thermal shock resistance permits fast temperature changes without damage. This is essential in applications like semiconductor production or glass manufacturing. Chemical inertness guarantees compatibility with acids, antacid, and solvents.

Manufacturing procedures consist of precision sintering and grinding. This makes sure constant top quality and exact dimensions. Custom-made finishings or surface therapies can be included in enhance functionality.

High firmness zirconia ceramics use reliability in demanding problems. They reduce downtime and upkeep costs. Industries gain from extended equipment lifespan and enhanced functional efficiency.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk

High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk is a durable material for industrial use. Here are 5 FAQs. What is this ceramic block used for? It is used in machinery parts, wear-resistant components, high-temperature equipment, and precision tools. The holes allow easy installation or fluid flow in systems like pumps or valves. The material’s hardness reduces wear and extends part life.

Why choose zirconia over other ceramics? Zirconia has higher toughness and strength. It resists cracks better than alumina or silicon carbide. The high hardness (over 1200 HV) makes it suitable for heavy friction environments. It also handles thermal shock better. This reduces breakage risks in sudden temperature changes.

Can it work in high-temperature conditions? Yes. It withstands temperatures up to 2000°C in inert environments. In oxygen-rich settings, it works up to 600°C. This makes it ideal for furnaces, engines, or aerospace parts. The low thermal expansion keeps dimensions stable under heat.

What sizes and hole specifications are available? Blocks come in standard sizes like 50x50x20mm or 100x100x30mm. Holes range from 1mm to 20mm in diameter. Custom sizes and hole patterns are possible. Precision grinding ensures tight tolerances for exact fits in machinery.

How is maintenance handled? The material requires minimal upkeep. It resists corrosion from chemicals, acids, and alkalis. Cleaning involves wiping with a dry cloth or mild solvent. Avoid harsh abrasives to prevent surface scratches. Regular checks for cracks or wear are enough for long-term use.

(High Hardness Zirconia Ceramic Block With Hole Zirconia Ceramic Brick ZrO2 Ceramic Chunk)

REQUEST A QUOTE

RELATED PRODUCTS

Customizable High-precision Colored Industrial Ceramics.Alumina Ceramic.zirconia Ceramic

High Temperature Yellow High Hardness Strength Magnesium Stabilised Zirconia CeramicPin Magnesia Stabilized Zirconium Rod

Customize High-Tech New Silicon Carbide Advanced Precision Industrial Alumina Zirconia Macor Structural Ceramic Mechanical Parts

Big Capacity Zirconium Oxide Ceramic Ball Milling Tank Zirconia Planetary Ball Mill Jar With Lid

Industrial Ceramic Manufacture Zirconium Oxide Part Zirconia Ceramics Sleeve