Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(High Precision Glazed ZrO2 Zirconia Ceramic Rod)

Specifications of High Precision Glazed ZrO2 Zirconia Ceramic Rod

High Accuracy Glazed ZrO2 Zirconia Ceramic Rods are made for requiring commercial and technical applications. These rods are made from zirconium dioxide (ZrO2), a material understood for phenomenal strength, use resistance, and thermal stability. The surface area is polished to a smooth glaze, minimizing rubbing and boosting efficiency in high-stress settings.

The rods are readily available in diameters ranging from 1mm to 20mm. Sizes can be customized up to 300mm. Tight dimensional tolerances are maintained, commonly within ± 0.01 mm. This guarantees reputable fit and feature in accuracy settings up.

Zirconia ceramic offers high solidity, ranked at approximately 1200 HV. It withstands wear also under continual mechanical stress. The product holds up against temperature levels approximately 1500 ° C without losing structural honesty. Thermal shock resistance is superb, permitting quick temperature adjustments without splitting.

Chemical inertness makes these poles suitable for harsh environments. They resist acids, alkalis, and solvents. This property is important in chemical handling and medical applications. Electrical insulation properties are solid, with a dielectric toughness exceeding 10 kV/mm.

The glazed surface area reduces wetness absorption, keeping the product stable in damp conditions. Surface roughness is managed below Ra 0.1 μm after polishing. This smooth surface minimizes fragment generation in cleanroom settings.

Applications include accuracy bearings, semiconductor manufacturing devices, medical implants, and aerospace components. The poles are used in pump seals, reducing instruments, and sensing unit probes. Their biocompatibility fulfills ISO 13356 standards for clinical tools.

Custom-made sizes and shapes are offered. Additional machining solutions, such as threading or grooving, can be applied to fulfill certain style requirements. Material certifications and examination reports are offered to ensure compliance with sector requirements.

Manufacturing utilizes advanced sintering techniques to attain high density and marginal porosity. Each batch undertakes extensive quality look for measurements, surface quality, and mechanical residential or commercial properties. Packaging is made to prevent damages throughout shipping.

These rods work with automated handling systems. They integrate flawlessly right into high-speed production procedures. Preparations vary based upon order requirements, with conventional sizes shipped within 7-10 organization days.

(High Precision Glazed ZrO2 Zirconia Ceramic Rod)

Applications of High Precision Glazed ZrO2 Zirconia Ceramic Rod

High precision polished ZrO2 zirconia ceramic rods are commonly utilized in sectors calling for sturdiness and precision. These rods are made from zirconium dioxide, a product recognized for stamina and resistance to put on. The polished surface area adds smoothness, lowering friction and protecting against contamination. This makes them ideal for atmospheres where accuracy and sanitation matter.

In clinical devices, these rods play an essential duty. Their biocompatibility guarantees they are risk-free for implants and surgical devices. They withstand rust and chemicals, making them suitable for sanitation. Oral tools and joint replacements frequently utilize them due to their ability to hold up against body liquids and mechanical tension.

Industrial applications rely upon these poles for high-performance parts. They handle severe temperatures and pressure without degrading. Machinery parts like bearings, seals, and reducing tools gain from their solidity and low thermal growth. This minimizes downtime and maintenance prices in making procedures.

Electronic devices and optics also utilize polished zirconia rods. Their insulating buildings prevent electrical disturbance in delicate equipment. In fiber optics, their security makes sure signal accuracy. Laser systems and sensors use them for placement due to their dimensional accuracy and warm resistance.

Aerospace and vehicle markets worth these poles for critical parts. They are made use of in gas cells, sensors, and engine parts. Their lightweight nature and capability to run under stress and anxiety boost performance and reliability in high-speed or high-temperature problems.

The combination of mechanical stamina, thermal security, and chemical inertness makes glazed ZrO2 rods functional. Customized sizes and shapes are attainable through advanced manufacturing, meeting details demands throughout sectors. Their lengthy life span and minimal wear add to set you back savings and boosted performance sought after applications.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Precision Glazed ZrO2 Zirconia Ceramic Rod

What is High Precision Glazed ZrO2 Zirconia Ceramic Rod?

This ceramic rod is made from zirconium dioxide (ZrO2). It has a glazed surface for extra smoothness. The manufacturing process ensures tight size control. It suits applications needing exact dimensions.

Why pick this ceramic rod over others?

ZrO2 offers high strength and toughness. The glazed layer improves wear resistance. It resists high heat well. It handles tough environments without breaking down. These features make it last longer than many alternatives.

Where is this rod commonly used?

Industries like aerospace and medical devices rely on it. It works in cutting tools, sensors, and bearings. High-temperature furnaces use it for structural support. Its precision fits lab equipment and electronics.

How does it compare to alumina ceramic rods?

ZrO2 is tougher and less brittle. It bends more before breaking. Alumina has higher hardness but lower fracture resistance. ZrO2 performs better under sudden stress. The glaze adds extra protection against scratches.

Can this rod handle chemicals and moisture?

Yes. The material resists most acids, alkalis, and solvents. The glaze blocks water absorption. It stays stable in humid or wet conditions. This prevents corrosion or swelling over time.

(High Precision Glazed ZrO2 Zirconia Ceramic Rod)

REQUEST A QUOTE

RELATED PRODUCTS

4D Pro High – Transparency and High – Brightness Dental Zirconia Ceramic Block Comparable to Real Teeth

High Temperature Heat Resistant Insulating Zirconia Ceramic Tube Sleeve

Factory Production Zirconia Ceramic

Sintyron Custom Ceramic Zirconia Ceramic Ring

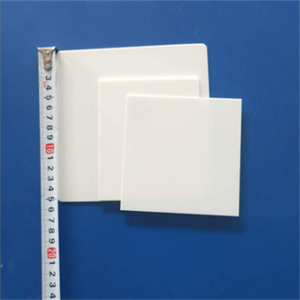

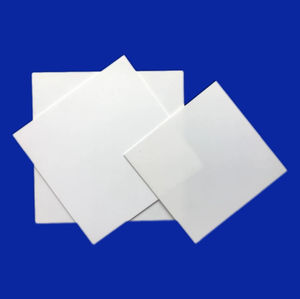

ZrO2 Zirconium Oxide Zirconia Ceramic Sheet