Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(High Purity Nano Zirconia Ceramic Powder)

Specifications of High Purity Nano Zirconia Ceramic Powder

High pureness nano zirconia ceramic powder is made for advanced industrial applications. The product offers remarkable efficiency because of its exact specs. The pureness degree exceeds 99.9%, reducing contaminations that could impact efficiency. Particle size varies between 20 and 50 nanometers, making sure uniform distribution in composite materials. This great bit dimension enhances sintering task, resulting in dense ceramic frameworks after handling.

The powder exists in multiple crystalline phases, consisting of tetragonal, monoclinic, and cubic. Stage structure can be customized to meet specific application needs. The tetragonal stage supplies high crack sturdiness, ideal for architectural parts. The monoclinic phase boosts wear resistance, suitable for cutting devices. The cubic stage uses remarkable oxygen ion conductivity, useful in fuel cells.

Surface steps 15– 30 m TWO/ g, advertising sensitivity in chemical processes. High surface permits reliable catalytic support and faster response prices. The mass thickness stays in between 0.8 and 1.2 g/cm FIVE, making certain very easy handling throughout production. After sintering, the material attains a density over 6.0 g/cm ³, adding to mechanical toughness.

Thermal stability extends up to 2400 ° C, making it suitable for high-temperature settings. The reduced thermal expansion coefficient lowers stress and anxiety under rapid temperature changes. Chemical resistance is superb, enduring acids, antacid, and destructive gases. This makes certain lasting sturdiness in harsh problems.

Applications extend aerospace, clinical gadgets, electronics, and energy sectors. In aerospace, it reinforces elements exposed to severe warmth. Medical implants gain from its biocompatibility and put on resistance. Electronics suppliers utilize it as a shielding layer in semiconductors. Coatings made from this powder protect surfaces from abrasion and deterioration. It likewise serves as a catalyst carrier in chain reactions.

Custom-made particle dimension circulations and phase proportions are available. The powder goes through stringent quality assurance, including X-ray diffraction and electron microscopy. This guarantees consistency throughout sets. Product packaging alternatives include moisture-resistant containers to preserve product integrity during storage space and transport.

(High Purity Nano Zirconia Ceramic Powder)

Applications of High Purity Nano Zirconia Ceramic Powder

High purity nano zirconia ceramic powder is an innovative material with several uses throughout various markets. Its little bit dimension and high pureness make it appropriate for applications requiring strength, warmth resistance, and chemical security.

In electronics, this material is used to make elements like sensors and capacitors. It works well in circuits since it stands up to electrical energy and manages high warm. Mobile phone and computers benefit from its capability to maintain parts stable under stress.

The clinical field uses nano zirconia ceramic powder for implants and dental items. It is secure for the body and lasts long. Oral crowns and joint substitutes made from it are solid and do not put on down easily. This decreases the requirement for constant substitutes.

Industrial tools and layers often include this product. Cutting tools covered with nano zirconia remain sharp longer and deal with high temperatures. This enhances efficiency in production. It is also contributed to engine parts in cars and trucks and planes to decrease wear and extend life-span.

Energy storage space systems like fuel cells and batteries utilize nano zirconia ceramic powder. It assists move ions effectively, enhancing efficiency. Photovoltaic panel and wind turbines use it to secure parts from severe problems, guaranteeing stable energy production.

Aerospace applications rely on this material for heat shields and engine elements. It holds up against extreme temperature levels throughout flights. Its lightweight helps in reducing fuel use while keeping safety requirements.

Study remains to locate new usages for high pureness nano zirconia ceramic powder. Its versatility and integrity make it a crucial material in fixing contemporary engineering difficulties. Industries value it for boosting item performance and longevity.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Nano Zirconia Ceramic Powder

High Purity Nano Zirconia Ceramic Powder is a fine, advanced material with particles sized between 1-100 nanometers. It is made using chemical synthesis methods like sol-gel or hydrothermal processes. The powder has high thermal stability, mechanical strength, and chemical resistance. It is used in industries needing durable, heat-resistant materials.

What industries use this powder?

It is common in electronics, medical devices, aerospace, and energy. Electronics manufacturers use it for sensors and capacitors. Medical fields apply it in dental implants and prosthetics. Aerospace relies on it for engine parts and thermal coatings. Energy sectors use it in fuel cells and solar panels.

What makes it better than traditional ceramics?

The nano-sized particles give it higher density and smoother surfaces. This improves strength and wear resistance. It handles extreme temperatures better. Chemical stability prevents corrosion. These traits make it last longer in harsh conditions.

Is it safe to handle?

The powder is non-toxic but requires careful handling. Inhalation risks exist due to tiny particles. Use protective gear like masks and gloves. Work in ventilated areas. Follow safety guidelines for nanomaterials. Store it in sealed containers away from moisture.

Can the powder be customized?

Yes. Particle size, purity, and surface treatments are adjustable. Specific needs like doping with other elements are possible. Customization ensures compatibility with different manufacturing processes. Suppliers often work with clients to meet exact requirements.

How does purity affect performance?

Higher purity reduces impurities that weaken the material. This improves sintering quality and final product durability. Applications needing reliability, like medical implants, demand purity above 99.9%. Lower grades may suit less critical uses.

(High Purity Nano Zirconia Ceramic Powder)

REQUEST A QUOTE

RELATED PRODUCTS

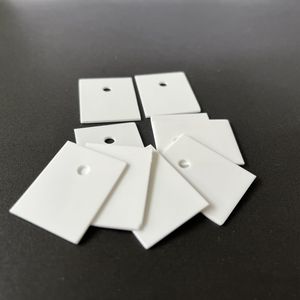

High Strength Flat Pad Customized Processing Zirconia Insulation Ceramic Ring Wear-resistant Insulation Ceramic Seal Ring

ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates

High Purity Zirconium Oxide Powder (zro2) Nano Ceramic Zirconia Powder for Electrostatic Coatings

Factory Direct Silicon Carbide/Zirconia /Al2O3 Alumina Ceramic Foam Filter Ceramic Filter Foam Ceramic Plate for Foundry

Customized Pen Point Tube Rod Zro2 Zirconia Ceramic Structural Parts for Metallurgy