Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

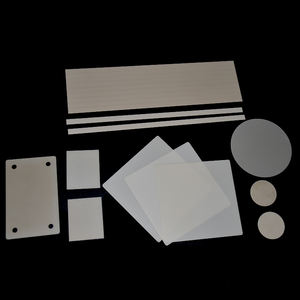

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From )

Specifications of High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From

High pureness zirconia ceramic powder is developed for industrial ceramics made use of in grinding media. It offers extraordinary security and performance in high-stress settings. The powder includes over 99.9% zirconium oxide, ensuring marginal contaminations. This high purity lowers contamination threats throughout grinding processes. The material’s dense structure boosts wear resistance, prolonging the life expectancy of grinding media.

Zirconia ceramic powder preserves security under extreme mechanical stress. It resists fracturing and breaking even during long term procedures. The powder’s uniform bit size circulation ensures constant sintering outcomes. This uniformity improves the final product’s mechanical strength and integrity.

The material excels in chemical resistance. It endures acidic and alkaline settings without weakening. This building is critical for sectors such as drugs or chemicals. Grinding media made from this powder remain inert, stopping reactions with refined materials.

Thermal security is another essential function. The powder retains architectural integrity at temperature levels approximately 800 ° C. It resists thermal shock, making it appropriate for high-temperature applications. This stability lessens deformation or failing threats during rapid temperature level changes.

Resilience is focused on in the powder’s style. Grinding media created from it show reduced wear prices, minimizing substitute regularity. This decreases operational prices for markets such as mining or electronic devices. The high crack toughness protects against unexpected malfunctions, making certain continuous operations.

Adjustable particle sizes are offered to meet certain commercial demands. Fine-tuning fragment dimensions enhances grinding performance for different materials. The powder’s compatibility with different creating methods allows versatile manufacturing.

This zirconia ceramic powder is suitable for requiring applications. Its mix of pureness, strength, and security supports reliable performance. Industries gain from minimized downtime and improved item high quality. The powder’s properties make it a preferred selection for sophisticated grinding services.

(High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From )

Applications of High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From

High purity zirconia ceramic powder is a key material in industrial porcelains. It uses superb performance in grinding media applications. The security of this product makes it ideal for demanding settings. Grinding media made from high purity zirconia ceramic powder stand up to wear efficiently. This extends the lifespan of tools and minimizes replacement prices. The powder’s high thickness and hardness stop contamination during grinding. This makes certain regular item top quality in markets such as drugs and electronic devices.

Zirconia ceramic powder reveals strong thermal stability. It keeps efficiency under heats. This is essential in procedures involving warmth, such as metal processing or chain reaction. The material’s resistance to rust adds worth. It functions well in acidic or alkaline problems without degrading. This makes it ideal for rough industrial settings.

The uniform fragment size of high pureness zirconia powder enhances producing precision. It permits even sintering throughout production. This causes ceramics with minimal issues and high structural integrity. Grinding media made this way take care of hefty lots without fracturing. They remain secure under mechanical stress, making sure reputable procedure.

Industries like mining, layers, and aerospace use zirconia-based grinding media widely. In mining, it squashes difficult materials effectively. In layers, it generates great, uniform particles for smooth finishes. Aerospace applications count on its durability for accuracy components. The material’s convenience fulfills diverse industrial requirements.

High purity zirconia ceramic powder is cost-efficient gradually. Its longevity reduces upkeep and downtime expenditures. The material’s eco-friendly nature straightens with sustainability goals. It generates much less waste contrasted to standard options. This supports cleaner production processes.

The mix of wear resistance, thermal stability, and chemical inertness makes high pureness zirconia ceramic powder a leading option. Its role in boosting grinding media efficiency is unrivaled. Industries benefit from enhanced efficiency and product quality.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From

High purity zirconia ceramic powder is popular in industrial ceramics. People often ask these questions about its use in grinding media stability.

What makes high purity zirconia powder good for grinding media? The powder has almost no impurities. This makes it strong under pressure. It resists cracking and lasts longer in harsh grinding conditions.

Why does high purity matter for stability? High purity ensures the material stays uniform. Uniformity stops weak spots from forming. Grinding media stays stable during repeated use. It keeps its shape and doesn’t wear down fast.

Which industries use this powder for grinding media? Industries needing precise results use it. Examples include pharmaceuticals, electronics, and chemicals. It works in equipment grinding materials to fine sizes. High purity prevents contamination of sensitive products.

Can the powder be customized for specific needs? Yes. Adjustments like particle size or additives are possible. Custom mixes fit different machines or materials. This solves unique challenges in grinding processes.

How does zirconia compare to other ceramic materials? Zirconia is tougher than alumina or silicon carbide. It wears slower under stress. Even with high heat or pressure, it stays stable. This reduces replacement costs and downtime.

(High Purity Zirconia Ceramic Powder for Industrial Ceramics for Grinding Media Stability Feature Direct From )

REQUEST A QUOTE

RELATED PRODUCTS

Custom Industrial High Precision High Hardness Polish Zirconia Ceramic Parts Zirconium Oxide Ceramic

High Strength HT/ST White CADCAM Zirconia Dental Ceramic Block Zirconium Blank

Supply Cold Isostatic Pressing Zirconia ceramic Machined Parts Sleeve

Zirconium Dioxide Zro2 Zirconia Powder Zirconium Oxide Ceramic Powder Per Ton

Zirconium Powder Ceramic Industries Grade Monoclinic Zirconia Powder For Insert