Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

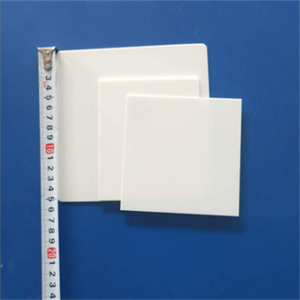

(Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls)

Specifications of Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls

Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls are engineered for demanding industrial applications. These ceramic balls combine micro silica and zirconia to achieve exceptional performance. The material composition ensures high wear resistance and durability. This makes them ideal for environments with heavy abrasion or impact.

The ceramic balls feature a high purity level of over 99.5%. This minimizes contamination in sensitive processes. They maintain structural integrity under extreme temperatures. The maximum operating temperature reaches 1600°C. Thermal shock resistance prevents cracking during rapid temperature changes.

Hardness is a critical attribute. These balls score above 8.5 on the Mohs scale. This surpasses most metals and traditional ceramics. The high hardness reduces surface wear during prolonged use. A low friction coefficient further enhances longevity. This is vital for machinery requiring smooth operation.

Surface finish options include polished and matte. Polished surfaces reduce friction in precision equipment. Matte finishes improve grip in mixing or grinding applications. Custom sizes range from 0.5mm to 50mm in diameter. Standard tolerances ensure consistent performance across batches.

Chemical inertness is another advantage. The ceramic balls resist acids, alkalis, and solvents. This suits them for chemical processing or pharmaceutical industries. Electrical insulation properties prevent conductivity-related issues.

Applications span multiple sectors. They are used in bearings, valves, pumps, and grinding mills. The mining industry relies on them for ore processing. Electronics manufacturers use them in precision components. Food-grade variants meet hygiene standards for processing equipment.

Density ranges between 3.8 and 4.2 g/cm³. This balances weight and strength for dynamic systems. Fracture toughness exceeds 6 MPa·m¹/². This reduces breakage risks under high stress.

Customization is available for specific needs. Options include unique dimensions, surface treatments, or material blends. Bulk orders maintain cost efficiency for large-scale operations. Packaging ensures safe transit to prevent damage.

These ceramic balls comply with international quality standards. Certifications include ISO 9001 and RoHS. Testing protocols validate performance metrics before delivery.

(Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls)

Applications of Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls

Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls serve critical roles across industries. These ceramic balls are crafted from advanced materials. Their high purity ensures minimal contamination. This makes them ideal for sensitive applications. The ivory white color reflects their refined composition. These balls excel in extreme conditions. They resist wear, heat, and corrosion effectively.

In grinding and milling processes, these ceramic balls are widely used. They crush materials efficiently. Their hardness reduces particle wear during operations. This extends equipment life. Maintenance costs drop as a result. Industries like mining and chemicals rely on them. They handle abrasive substances without degrading.

Chemical processing plants use these balls as catalyst supports. Their stability ensures consistent reactions. Harsh acids or alkalis do not damage them. This reliability boosts production efficiency. High-temperature environments like kilns also benefit. The balls withstand intense heat without cracking. Thermal shock resistance keeps them intact during rapid temperature changes.

The electronics industry values their insulating properties. They prevent electrical interference in delicate components. Their smooth surface minimizes friction. This reduces energy consumption in moving parts. Automotive manufacturers use them in bearings and valves. They enhance performance under heavy loads.

Pharmaceutical applications demand high purity. These ceramic balls meet strict hygiene standards. They avoid contaminating medical products. Food processing equipment uses them for similar reasons. Their non-reactive nature ensures product safety.

Durability makes these balls cost-effective over time. They outlast traditional metal alternatives. Replacement frequency decreases. Downtime is minimized. Industries save resources while maintaining output. Their versatility spans sectors from energy to aerospace.

Micro Silica Zirconia Ceramic Balls adapt to evolving industrial needs. They address challenges in harsh environments. Performance remains consistent under stress. These qualities make them essential in modern manufacturing.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls

Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls are used widely in tough industrial settings. Here are five common questions about them. What are these ceramic balls made of? They are made from zirconia, micro silica, other high-purity materials. This mix gives them extreme hardness, excellent wear resistance. They work well in machinery parts, chemical processing equipment. Their ivory white color shows high material purity.

Why pick these ceramic balls over metal or other ceramics? These balls are harder than steel, most ceramics. They resist corrosion better. They handle high temperatures, heavy friction without cracking. This cuts downtime, lowers replacement costs. Industries like mining, grinding use them for long-lasting performance.

Where can these ceramic balls be used? They fit in pumps, valves, bearings, any high-wear equipment. Chemical plants use them for mixing corrosive liquids. Mining machines use them to crush hard materials. They suit places needing materials that last under stress, high heat.

Can these balls be customized in size? Yes. Standard sizes range from 1mm to 50mm diameters. Custom sizes are possible. Provide details like dimensions, tolerance levels. Manufacturers adjust production to meet specific needs.

How do you maintain these ceramic balls? They need little maintenance. Clean them with mild detergents, soft brushes. Avoid harsh chemicals, abrasive tools. Check for chips, cracks regularly. Replace damaged balls quickly to keep equipment running smoothly. Their wear resistance means less frequent checks compared to other materials.

(Micro Silica Zirconia Industrial Ceramic Ivory White High Purity Wear Ceramic Balls)

REQUEST A QUOTE

RELATED PRODUCTS

Various Zirconia Ceramic Saw Cutting Blades

Refractory Industry Nano Ceramic Zirconia Ceramic Powder Zirconium Dioxide Zro2 Zirconia Blasting Media

Ceramic Tooth Zirconia Powder Color Zirconia /ZrO2/Zirconium Oxide for A2 Series Dental Block

Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality

Direct ing Textile Machine Accessories ZrO2 Ceramic Ring ‘s Valve Sealing Rod Zirconia Ceramic Material