Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

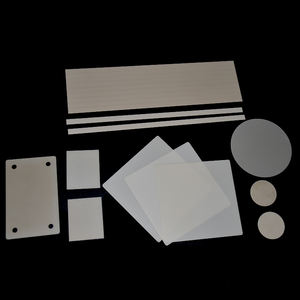

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process)

Specifications of Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process

Nano Ceramic YSZ Yttrium Supported Zirconia Powder is made for advanced industrial applications. This high-purity material includes zirconia supported with yttrium oxide. The make-up makes certain phenomenal thermal stability and mechanical strength. The powder is perfect for the completely dry pressing procedure. This approach includes condensing the powder right into mold and mildews under high pressure. The result is dense, uniform ceramic elements with marginal defects.

The powder has a bit dimension ranging from 50 to 100 nanometers. Little bit dimension enhances sintering performance. This causes higher final product density. The purity level surpasses 99.9%. Contaminations like silica and alumina are snugly regulated. Reduced pollutant levels prevent weakening of the ceramic structure. The yttrium material is commonly 3-8 mol%. This maintains the zirconia in its tetragonal stage. The phase improves crack durability and use resistance.

Dry pressing uses automated hydraulic or mechanical presses. Stress used ranges from 100 to 300 MPa. Uniform pressure distribution is critical. It prevents fractures or thickness variations. Binders are occasionally added to improve environment-friendly stamina. Binders burn off during sintering. This leaves no residue in the final product.

Sintering happens at temperatures between 1400 ° C and 1600 ° C. The procedure attains over 95% theoretical thickness. Finished items show marginal contraction. Dimensional accuracy is kept within limited tolerances. This makes the material suitable for accuracy elements.

Key applications include dental implants, cutting devices, and oxygen sensing units. The powder’s thermal insulation residential or commercial properties profit aerospace finishes. Its biocompatibility supports clinical device manufacturing. Customized bit dimension circulations are readily available. This fulfills details consumer needs.

The completely dry pushing procedure reduces material waste. It is cost-effective for automation. Constant top quality is made sure with extensive screening. Specifications like bit morphology and flowability are monitored. Batch-to-batch harmony is ensured.

Storage conditions require a dry, trendy setting. Moisture exposure have to be stayed clear of. Appropriate handling prevents contamination. Packaging utilizes moisture-resistant secured containers. Shelf life prolongs up to 12 months under excellent conditions.

Technical assistance is offered procedure optimization. Custom formulas attend to one-of-a-kind commercial difficulties. The product complies with global quality standards. Qualifications consist of ISO 9001 and RoHS.

(Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process)

Applications of Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process

Nano ceramic YSZ (Yttrium Stabilized Zirconia) powder is extensively utilized in sophisticated manufacturing due to its distinct residential properties. The completely dry pushing procedure shapes this powder into high-performance components. This approach involves condensing the powder into mold and mildews under high pressure. It produces thick, consistent structures optimal for demanding applications.

One significant use of YSZ powder remains in oxygen sensors for automobile systems. These sensors check exhaust gases to optimize gas efficiency. The material’s security at high temperatures makes sure precise analyses. It also resists deterioration in extreme atmospheres. This makes it reputable for lasting usage in automobiles.

YSZ-based elements are important in solid oxide fuel cells (SOFCs). These cells create electricity via electrochemical responses. The powder’s high ionic conductivity permits efficient ion transportation at elevated temperatures. Dry pressing generates slim, resilient electrolyte layers. These layers are necessary for keeping cell efficiency and long life.

The clinical area take advantage of YSZ’s biocompatibility. Dental implants and prosthetics made with this product incorporate well with human cells. The completely dry pressing approach makes sure precise shaping for customized clinical devices. The result is strong, wear-resistant items that satisfy rigorous wellness standards.

In aerospace, YSZ layers protect turbine blades from severe warm. The powder’s reduced thermal conductivity avoids damage during procedure. Dry pushing types these layers right into limited, crack-free layers. This extends the life expectancy of engine elements.

Industrial tools like reducing inserts utilize YSZ for improved toughness. The material’s hardness reduces wear during machining. Dry pushing enables automation of complex forms with constant high quality. This lowers manufacturing expenses while preserving performance.

The electronic devices market applies YSZ in substratums and insulators. Its electrical resistance and thermal security suit high-power devices. Dry-pressed parts guarantee very little flaws in sensitive digital systems.

This powder is additionally used in accuracy optics. Components like lenses and mirrors call for smooth surfaces. The completely dry pushing procedure achieves great details without post-processing. This saves time and sources in manufacturing.

Nano ceramic YSZ powder sustains innovations across several industries. The dry pressing method fulfills the demand for trusted, high-quality parts. Industries rely on this mix for advanced technological services.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process

Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process FAQs

What makes the dry pressing method good for YSZ powder?

Dry pressing works well for YSZ powder because it compacts the material tightly. This creates strong, dense ceramic parts. The process uses high pressure without adding liquids. This saves time by skipping drying steps. It also reduces cracks or flaws in the final product.

Why does particle size matter in dry pressing?

Smaller particles pack closer together during pressing. This improves the material’s strength and smoothness. Uniform particle size stops uneven gaps from forming. These gaps weaken the ceramic. Nano-sized YSZ powder gives better results than larger grains.

How does pressing temperature affect the outcome?

Higher temperatures soften the powder slightly. This helps particles stick together under pressure. Too much heat can make the powder stick to the mold. Room temperature works for most dry pressing. Special cases might need controlled heating.

Are there limits to dry pressing for YSZ ceramics?

Dry pressing struggles with complex shapes. Simple, flat designs work best. Intricate parts might need extra steps like machining after pressing. The method also requires precise pressure control. Uneven force causes weak spots or breaks.

What safety steps are needed when handling YSZ powder?

YSZ powder is fine and easy to breathe in. Use masks and gloves to avoid skin or lung contact. Keep the powder dry. Moisture makes it clump and ruins pressing. Store it in sealed containers. Clean tools after use to prevent contamination.

(Nano Ceramic YSZ Yttrium Stabilized Zirconia Powder Dry Pressing Process)

REQUEST A QUOTE

RELATED PRODUCTS

Custom ZrO2 Disc Polished Zirconia Ceramic Plate Zirconia Sheet Board

Factory Zirconia Ceramic Parts Precision Ceramic Parts Zirconium Ceramic

Zirconia Heating Elements Double Spiral Heater Heating Element Ceramic Sic Carbide Heater

ZrO2 Factory Top Grade Thin Wall Zirconia Ceramic Tube

0.2mm 0.3mm 5mm 10mm 15mm 20mm G5 G10 Polished Zro2 Zirconium Oxide Zirconia Ceramic Bearing Grinding Balls and Beads