Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

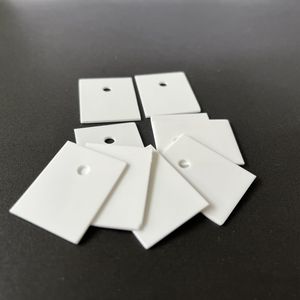

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

(Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder)

Specifications of Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder

Yttrium Stabilized Zirconium Silicate Steel Powder Layering Zirconia Toughened Fused Alumina ZTA Ceramic Powder is a high-performance material developed for innovative commercial applications. It integrates yttrium-stabilized zirconium silicate with zirconia-toughened alumina to create a sturdy ceramic composite. The powder features an exact chemical structure maximized for strength and thermal stability. Key elements include yttrium oxide, zirconium silicate, and light weight aluminum oxide. These aspects work together to enhance crack toughness and wear resistance.

The particle dimension distribution ranges from 0.5 to 10 microns. This guarantees consistent layering throughout application. Fine fragments enhance surface area finish. Coarser bits contribute to bulk density. The product keeps consistent flowability for simple handling in making procedures. It operates effectively in temperatures approximately 1600 ° C. High thermal shock resistance avoids cracking under quick temperature adjustments.

Mechanical properties include a Vickers solidity of 14-16 GPa. This makes it appropriate for unpleasant atmospheres. Flexural strength surpasses 500 MPa. Crack toughness gets to 6-8 MPa · m ¹/ ² due to zirconia phase makeover. The product resists chemical rust from acids, alkalis, and molten metals. This stability suits extreme commercial settings.

Applications consist of thermal obstacle finishes for gas turbines and aerospace parts. It serves as a wear-resistant layer in mining equipment and cutting devices. The powder is utilized in ceramic matrix compounds for auto engine parts. It enhances longevity in high-stress elements like bearings and seals. Electrical insulation residential or commercial properties make it optimal for electronic substratums.

Handling approaches include plasma splashing, sintering, and cold pressing. Compatibility with basic ceramic manufacturing methods makes sure wide usability. Personalized particle size and composition permit modifications for specific demands. The powder satisfies industry criteria for purity, with very little contamination degrees below 0.1%.

Storage requires completely dry problems to prevent dampness absorption. Product packaging makes use of moisture-resistant containers to maintain performance. Managing adheres to standard safety protocols for fine ceramic powders. The item is offered in bulk quantities for large-scale production.

(Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder)

Applications of Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder

Yttrium supported zirconium silicate steel powder layering zirconia toughened fused alumina (ZTA) ceramic powder is a high-performance material with diverse industrial usages. Its distinct blend of zirconia, alumina, and yttrium stablizing produces exceptional toughness, thermal resistance, and sturdiness. This makes it excellent for demanding atmospheres where integrity matters.

In aerospace and auto industries, the powder is utilized to coat engine components. It protects components like turbine blades and exhaust systems from severe heat and wear. The product’s thermal stability guarantees engines run efficiently under high tension. It lowers maintenance costs and extends equipment life expectancy.

The clinical field take advantage of this ceramic powder in implants and medical devices. Its biocompatibility and resistance to corrosion make it secure for lasting use in the body. Dental implants and joint substitutes made with this product program boosted longevity contrasted to standard options. People experience fewer complications gradually.

Industrial equipment counts on ZTA ceramic powder for wear-resistant components. Elements like seals, bearings, and reducing devices last longer when coated with this product. It deals with rough conditions in mining and manufacturing without deteriorating. This decreases downtime and improves performance.

Electronic devices makers use the powder in heat-resistant coatings for circuit card and semiconductors. It protects against overheating in high-power gadgets, ensuring stable efficiency. The material’s electrical insulation residential or commercial properties include added defense against brief circuits.

The energy field applies ZTA ceramic powder in oil and gas exploration tools. It stands up to extreme underground problems, including high pressure and harsh chemicals. Pierce bits and shutoffs coated with this powder maintain performance in difficult environments.

Environmental technology makes use of the product in catalytic converters and purification systems. Its thermal resilience aids break down pollutants in exhaust gases. Filters made with ZTA ceramic powder trap fine fragments more effectively, boosting air top quality.

This ceramic powder’s flexibility stems from its adjustable make-up. Adjusting the proportion of zirconia, alumina, and yttrium enables customizing properties for particular needs. Industries remain to find new applications as product science developments.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder

Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina (ZTA) Ceramic Powder is a high-performance material. It combines zirconia’s toughness with alumina’s hardness. Here are answers to common questions.

What is this ceramic powder used for?

It is used in industries needing strong, heat-resistant materials. Applications include aerospace parts, automotive components, cutting tools, and wear-resistant coatings. It protects surfaces exposed to extreme temperatures or friction.

How does it improve durability?

The yttrium stabilization prevents cracks in zirconia. Alumina adds hardness. The mix creates a material that resists breaking under stress. This makes parts last longer in harsh conditions.

Is it safe to handle?

Proper safety steps are needed. Wear gloves and masks to avoid inhaling particles. Store it in sealed containers away from moisture. Follow local rules for disposal to prevent environmental harm.

Can it be used in 3D printing?

Yes. It works with advanced manufacturing methods like additive manufacturing. The fine powder layers evenly. It is sintered at high temperatures to form dense, strong structures.

What sizes and grades are available?

The powder comes in different particle sizes. Options range from sub-micron to larger grains. Custom blends adjust zirconia-alumina ratios for specific needs. Suppliers provide technical support for choosing the right grade.

This ceramic powder is trusted for demanding applications. Its mix of strength and heat resistance meets industrial standards. Proper handling ensures safety and performance.

(Yttrium Stabilized Zirconium Silicate Metal Powder Layering Zirconia Toughened Fused Alumina Zta Ceramic Powder)

REQUEST A QUOTE

RELATED PRODUCTS

Dental Lab Stain And Glaze Zirconia Crowns Ceramic Glaze Powder Paste Glaze Paste

Zirconia Ceramic Zirconium Cylindrical Shape Grinding Media Zirconium Oxide ZrO2 Ceramic Grinding Cylinder

Refractory White Zirconia Powder Fused Yttria Stabilized Zirconium Oxide Powder for Ceramic Coating Thermal Spray

Industrial Grade 99.9% 50nm Nano Size Zirconia Zirconium Oxide Powder Used As Ceramics Coating and Refractory

Colorful Zirconia MSZ Yellow White Black Blue Zirconium Oxide Ceramic Insulation Plunger Rod