Discover Premium Ceramic Products | Durability & Elegance United | Advanced Ceramics

PRODUCT PARAMETERS

Description

Overview of Zirconium Dioxide Ceramics

Zirconium Dioxide Ceramics, known for their toughness and ability to withstand extreme temperatures, are widely used in medical, automotive, and industrial applications due to their unique properties.

Features of Zirconium Dioxide Ceramics

Exceptional fracture toughness

High thermal expansion

Excellent resistance to wear and corrosion

Biocompatibility for medical implants

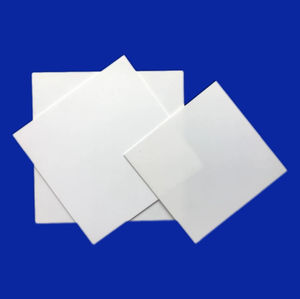

(ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates)

Specifications of ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates

ZrO2 boards are zirconium oxide ceramic plates created for high-temperature industrial applications. These setter plates handle extreme warmth and extreme conditions in kilns, furnaces, and sintering procedures. The product is made from high-purity zirconia, ensuring stability and sturdiness. It withstands thermal shock, indicating it won’t fracture when temperature levels alter rapidly. This makes it suitable for duplicated heating and cooling down cycles.

The boards have a dense structure with reduced porosity. This avoids contamination during production. They are chemically inert, so they don’t respond with metals, chemicals, or various other materials. These residential or commercial properties make them reputable for refining sensitive parts like digital porcelains or sophisticated alloys.

ZrO2 boards come in common sizes like 200x200mm or 300x300mm. Density varieties from 5mm to 25mm. Custom measurements are available for details demands. The surface area is smooth and level, ensuring even warm distribution. This minimizes warping or issues in ended up products.

These plates run in temperature levels up to 1600 ° C. They outperform standard materials like alumina or cordierite. Their high mechanical toughness withstands bending or breaking under heavy lots. This expands their service life, decreasing substitute costs.

ZrO2 boards are utilized in electronic devices, aerospace, and metallurgy. They sustain parts throughout firing, sintering, or heat therapy. Their thermal insulation properties boost power efficiency in commercial procedures. Very little wear gradually makes certain regular results batch after set.

Upkeep is basic. Clean home plates with non-abrasive tools to remove deposit. Prevent sudden temperature modifications throughout cooling to avoid stress and anxiety. Appropriate handling guarantees long-lasting performance.

The product is readily available in single plates or mass orders. Product packaging shields versus damages during shipping. Technical support aids consumers pick the best specifications for their needs.

(ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates)

Applications of ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates

ZrO2 boards, or zirconium oxide refractory sheets, offer critical duties in high-temperature industrial procedures. These ceramic plates handle severe warm, stand up to chemical corrosion, and keep structural stability under stress and anxiety. Industries like metallurgy, ceramics, and electronic devices rely on them for requiring applications.

In metallurgy, ZrO2 boards line heaters and kilns. They hold up against temperature levels over 2000 ° C without deteriorating. Their low thermal conductivity minimizes warmth loss, improving power efficiency. They likewise resist responses with liquified metals, making them perfect for crucibles and casting molds.

Ceramic production makes use of zirconia setter layers as kiln furniture. These plates sustain ceramic parts throughout firing. They stop warping or contamination of delicate items. Their high thermal shock resistance permits rapid home heating and cooling cycles without breaking. This speeds up manufacturing while preserving product top quality.

The electronic devices industry uses ZrO2 sheets as protecting components in high-temperature gadgets. They different components in gas cells, sensing units, and semiconductors. Their electrical insulation properties stop brief circuits. They likewise stand up to wear in unpleasant environments, expanding equipment life-span.

Zirconia setter plates are crucial in manufacturing sophisticated materials. They take care of processes like sintering, where powdered products fuse under warm. Home plates make certain even warm distribution, crucial for constant item results. Their non-reactive surface area prevents unwanted chemical communications throughout manufacturing.

Aerospace and automotive fields utilize these porcelains for thermal barrier and engine elements. They protect sensitive parts from extreme temperature levels. Their light-weight nature minimizes general system weight, enhancing performance.

ZrO2 boards require very little upkeep as a result of their sturdiness. They outlast traditional products like alumina or silicon carbide. This reduces downtime and substitute prices. Their adaptability makes them appropriate for custom remedies in specialized markets.

These plates are machined to exact dimensions for particular applications. Resistances as tight as 0.1 mm guarantee correct fit in complicated arrangements. Customized forms and openings accommodate unique manufacturing requirements.

Zirconia porcelains are picked for environments where failing is not an option. Their dependability in extreme conditions supports continuous industrial operations. Industries prioritize them for essential procedures demanding accuracy and durability.

Company Introduction

Advanced Ceramics founded on October 17, 2014, is a high-tech enterprise committed to the research and development, production, processing, sales and technical services of ceramic relative materials and products.. Since its establishment in 2014, the company has been committed to providing customers with the best products and services, and has become a leader in the industry through continuous technological innovation and strict quality management.

Our products includes but not limited to Silicon carbide ceramic products, Boron Carbide Ceramic Products, Boron Nitride Ceramic Products, Silicon Carbide Ceramic Products, Silicon Nitride Ceramic Products, Zirconium Dioxide Ceramic Products, Quartz Products, etc. Please feel free to contact us.(nanotrun@yahoo.com)

Payment Methods

T/T, Western Union, Paypal, Credit Card etc.

Shipment Methods

By air, by sea, by express, as customers request.

5 FAQs of ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates

What is ZrO2 Board Zirconium Oxide Refractory Sheet?

ZrO2 Board is a ceramic material made from zirconium oxide. It handles extreme heat well. It stays stable in temperatures up to 2400°C. This makes it ideal for industrial furnaces, kilns, or labs. Its low thermal conductivity helps save energy.

Why use zirconia ceramic setter plates?

Zirconia setter plates support items during high-temperature processes. They resist warping, cracking, and chemical reactions. These plates protect products from contamination. They last longer than traditional materials like alumina. Factories save money by reducing replacements.

How heat-resistant are these plates?

ZrO2 plates work in temperatures up to 2400°C. They keep their shape and strength even under rapid heating or cooling. This stability prevents damage during repeated use. They outperform metals or other ceramics in extreme conditions.

Are zirconia setter plates durable?

Yes. Zirconia’s toughness resists wear, impact, and thermal shock. These plates handle heavy loads without cracking. They survive harsh environments longer than alternatives. Their lifespan reduces downtime and maintenance costs.

How to maintain zirconia ceramic plates?

Clean plates after each use to remove debris. Avoid sudden temperature changes when heating or cooling. Store them in dry areas to prevent moisture absorption. Inspect for cracks or wear regularly. Proper care ensures consistent performance.

(ZrO2 Board Zirconium Oxide Refractory Sheet Zirconia Ceramic Setter Plates)

REQUEST A QUOTE

RELATED PRODUCTS

High Toughness Zro2 Zirconia Ceramic Plate Zirconium Oxide Ceramic Board

Al2O3 95% 99% 99.5% 99.6% 99.8% alumina zirconia ZTA ceramic piece sheet substrate high quality

Zirconium Dioxide Nozzle CNC Machining Zirconia Spray Nozzle Hot Zirconia Jet Nozzle Ceramic Parts

Aidite Dental Lab Full Ceramic Crown Zirconia Material Superfect Zir Dental Zirconia Blocks 3Dpro Zirconia

Dental High Quality Zirconia Ceramic Powder VM9 All-ceramic Ceramic Powder Dental Laboratory Consumables